Bismuth tungstate@MIL-100 (Fe) composite material, preparation method and application thereof

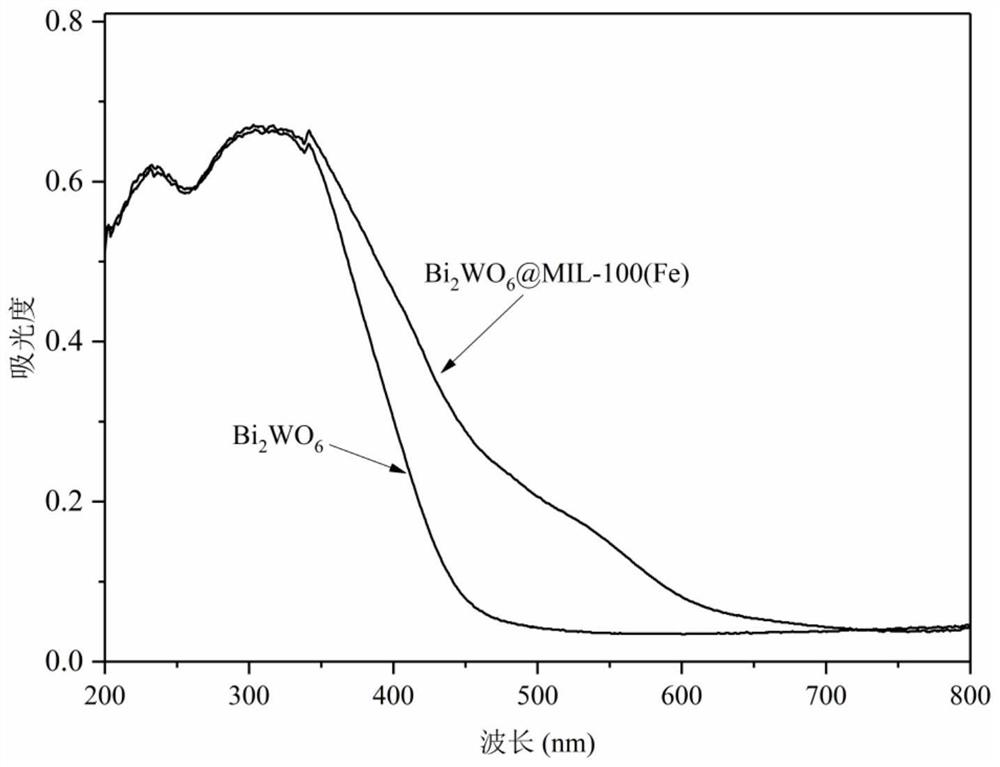

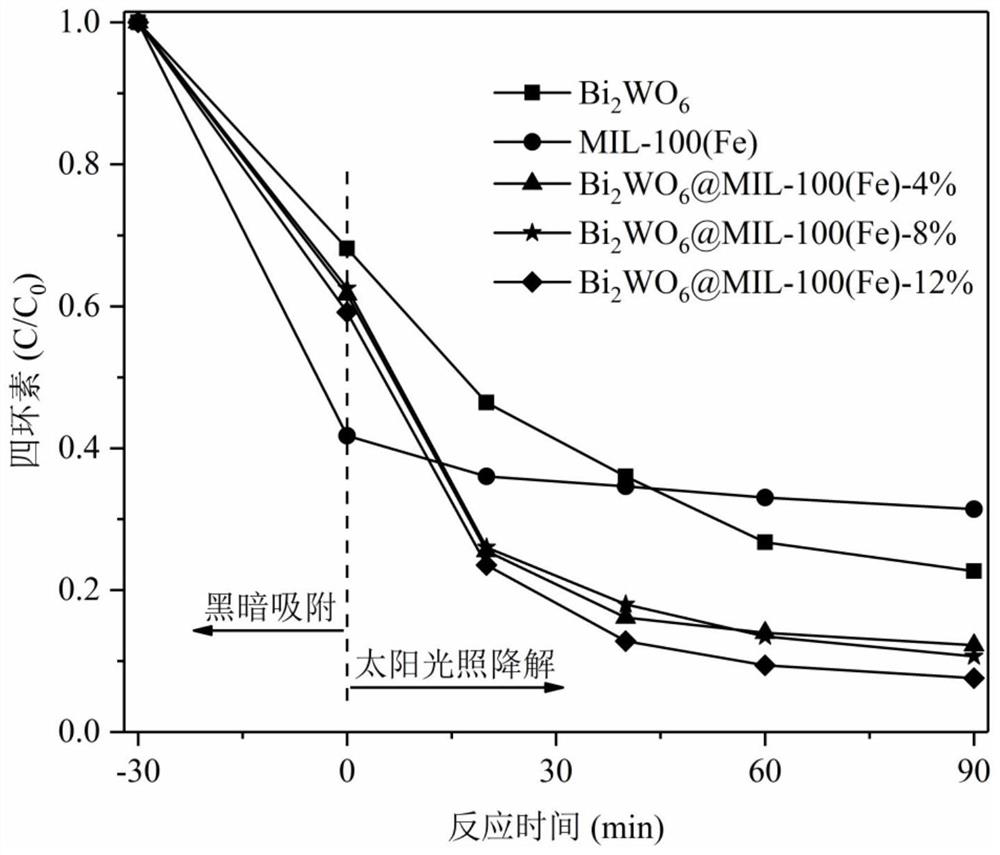

A composite material, bismuth tungstate technology, applied in chemical instruments and methods, catalyst activation/preparation, special compound water treatment, etc., can solve the problems of reducing photocatalytic activity, affecting photocatalytic effect, etc. The effect of photocatalytic activity and high removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of MIL-100(Fe) by hydrothermal method: Weigh 0.36mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) was dissolved in 36mL deionized water, then added 0.24mmol trimesic acid (C 9 h 6 o 6 ) and 3.24mL hydrofluoric acid (HF, 40wt%), stirred magnetically at room temperature for 1 hour, then transferred the above mixed solution to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, and placed it in a blast drying oven at 160 Continuous heating at ℃ for 12h. After the hydrothermal reaction is over, wait for the reaction kettle to cool down naturally, obtain the precipitate in the mixed solution by centrifugation, then pour the precipitate into 150mL water and ethanol in turn, and stir continuously for at least 2 hours in a water bath at 60°C to completely remove impurities , followed by suction filtration to obtain a solid powder product, which was dried in a vacuum oven at 70° C. for 12 hours, and the final product obtained was MIL-100...

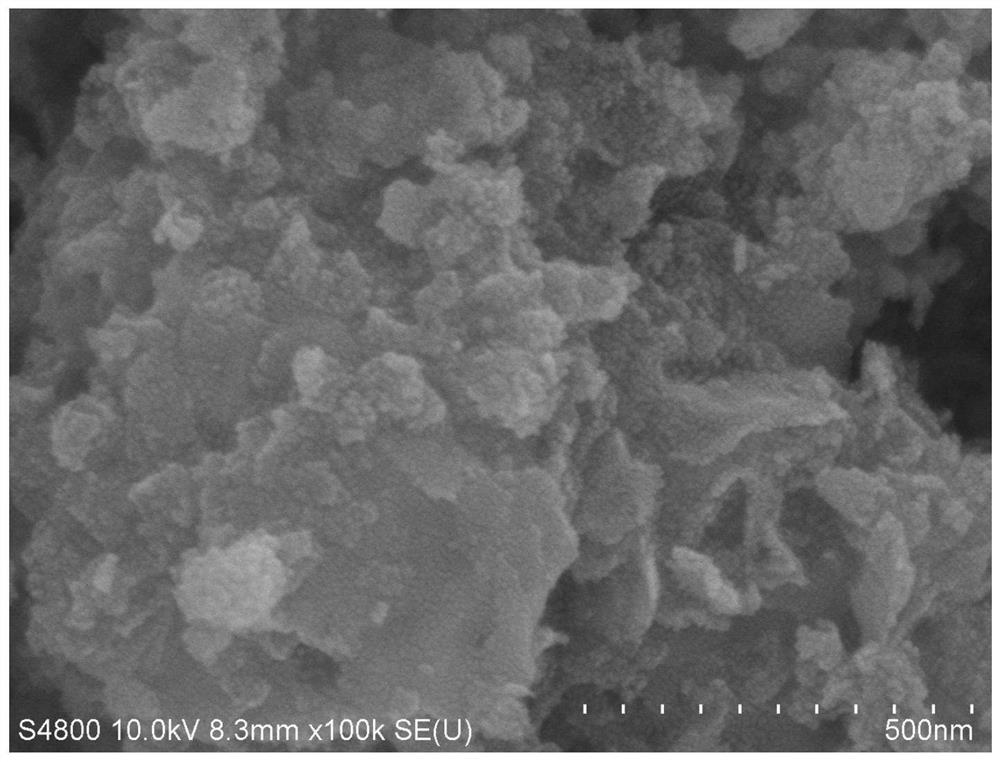

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, and the special features are:

[0027] (1) This step is the same as in Example 1

[0028] (2) Weigh 90mg cetyltrimethylammonium bromide (C 19 h 42 BrN) was completely dissolved in 80mL of deionized water, and then 165mg of sodium tungstate (Na 2 WO 4 2H 2 O), magnetically stirred at room temperature until the solution was clear. Then get 30mg of MIL-100(Fe) powder obtained in step (1) and add it to the previous solution, ultrasonically disperse it for 30min, then weigh 485mg of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) added to the above mixture. After stirring at room temperature for 1 h, the above mixture was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and placed in a blast drying oven at 120°C for continuous heating for 24 h. After the hydrothermal reaction is over, wait for the reaction kettle to cool naturally, obtain the precipitate in the mixed solution by centr...

Embodiment 3

[0031] This embodiment is basically the same as Embodiment 1, and the special features are:

[0032] (1) This step is the same as in Example 1

[0033] Weigh 50mg cetyltrimethylammonium bromide (C 19 h 42 BrN) was completely dissolved in 80mL of deionized water, and then 165mg of sodium tungstate (Na 2 WO 4 2H 2 O), magnetically stirred at room temperature until the solution was clear. Then get 15mg of MIL-100(Fe) powder obtained in step (1) and add it to the previous solution, ultrasonically disperse it for 30min, then weigh 485mg of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) added to the above mixture. After stirring at room temperature for 1 h, the above mixture was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and placed in a blast drying oven at 120°C for continuous heating for 24 h. After the hydrothermal reaction is over, wait for the reaction kettle to cool naturally, obtain the precipitate in the mixed solution by centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com