Running board bottom surface coating, preparation method thereof and running board

A running board and bottom surface technology, which is applied in the direction of epoxy resin coating, coating, etc., can solve the problems of running board bending, stress imbalance between the bottom surface and the top surface of the running board, etc., and achieve the advantages of not being easy to bend, stress balance, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

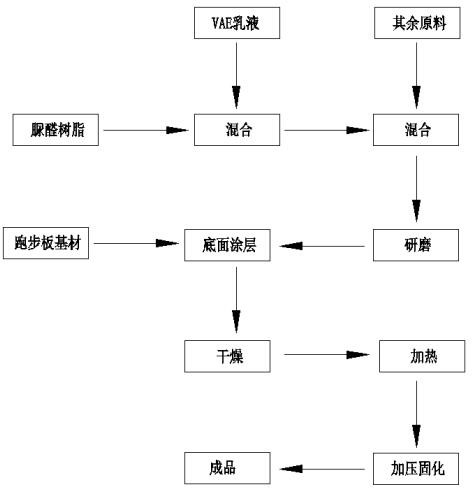

Method used

Image

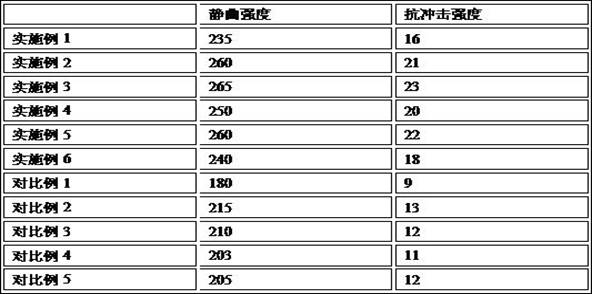

Examples

Embodiment 1

[0023] A running board bottom surface coating is composed of the following components by weight: 70 parts of urea-formaldehyde resin, 20 parts of VAE emulsion, 6 parts of calcium stearate, 0.5 part of calcium persulfate, 0.5 part of ammonium chloride, and 3 parts of pigment.

[0024] The preparation method of the coating of the above-mentioned embodiment, weighs urea-formaldehyde resin, VAE emulsion, calcium stearate, calcium persulfate, ammonium chloride and pigment according to the above-mentioned parts by weight, first mixes the urea-formaldehyde resin with the VAE emulsion, then adds the remaining raw materials together Grinding and dispersing evenly in a three-roller mill obtains the bottom surface coating of the running board;

[0025] A running board is formed by heat curing the above-mentioned coatings of the embodiment coated on the bottom surface of the running board by rollers, wherein the temperature of the heat curing is 300° C. and the time is 15s.

Embodiment 2

[0027] A running board bottom surface coating is composed of the following components by weight: 60 parts of urea-formaldehyde resin, 30 parts of VAE emulsion, 3 parts of calcium stearate, 0.1 part of calcium persulfate, 1.5 parts of ammonium chloride and 5.4 parts of pigment.

[0028] The preparation method of the coating of the above-mentioned embodiment, weighs urea-formaldehyde resin, VAE emulsion, calcium stearate, calcium persulfate, ammonium chloride and pigment according to the above-mentioned parts by weight, first mixes the urea-formaldehyde resin with the VAE emulsion, then adds the remaining raw materials together Grinding and dispersing evenly in a three-roller mill obtains the bottom surface coating of the running board;

[0029] A running board is formed by heat curing the above-mentioned coatings of the embodiment coated on the bottom surface of the running board by rollers, wherein the temperature of the thermal curing is 160° C. and the time is 30s.

Embodiment 3

[0031] A running board bottom surface coating is composed of the following components by weight: 62.5 parts of urea-formaldehyde resin, 25 parts of VAE emulsion, 5 parts of calcium stearate, 0.3 parts of calcium persulfate, 1 part of ammonium chloride, and 6.2 parts of pigments.

[0032] The preparation method of the coating of the above-mentioned embodiment, weighs urea-formaldehyde resin, VAE emulsion, calcium stearate, calcium persulfate, ammonium chloride and pigment according to the above-mentioned parts by weight, first mixes the urea-formaldehyde resin with the VAE emulsion, then adds the remaining raw materials together Grinding and dispersing evenly in a three-roller mill obtains the bottom surface coating of the running board;

[0033] A running board is formed by heat curing the above-mentioned paint of the embodiment coated on the bottom surface of the running board by a roller, wherein the temperature of the heat curing is 180° C. and the time is 25s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com