High polymer double-fiber grating micro-detection system and preparation method thereof

A dual-fiber grating and detection system technology, applied in measuring devices, using optical devices to transmit sensing components, converting sensor outputs, etc., can solve problems such as complex links, glass optical fibers that are easily broken, and susceptible to electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

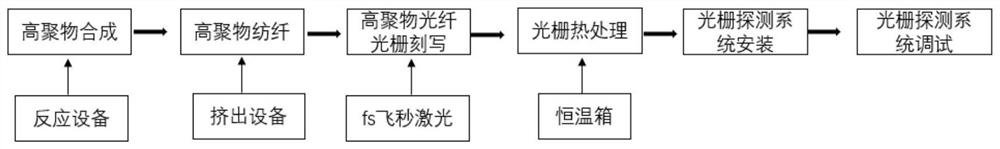

[0048] see figure 1 , the preparation method of polymer double fiber grating micro-detection system of the present invention, described preparation method comprises the following steps:

[0049] (1) Polymer optical fiber:

[0050] S1: Preparation of six copolymers with different refractive indices;

[0051] S101: Add monomer M8A: perfluoro-2-methyl-4,5-methylether-1,3-dioxolane, monomer M8C: perfluoro-2-methyl-4 into the reactor - Ethyl-1,3-dioxolane, initiator;

[0052] S102: stirring and purging with nitrogen gas, after the cleaning is completed, the reactor is heated under reduced pressure to carry out the polymerization reaction;

[0053] S103: After the reaction is completed, the reactant is dissolved with the solvent hexafluorobenzene, and then precipitated with the solvent chloroform, and after repeated dissolution and precipitation, the copolymer F is obtained;

[0054] The copolymer F obtains the copolymer F1, the copolymer F2, the copolymer F3, the copolymer F4, ...

Embodiment 1

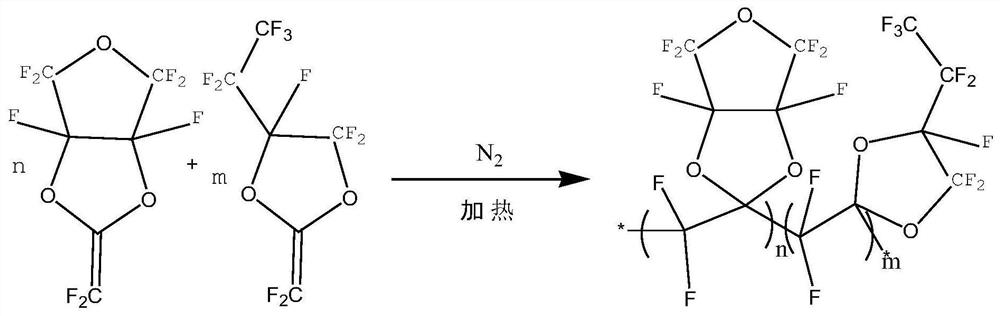

[0065] Such as image 3 As shown, the synthesis of copolymer F1

[0066] Copolymer F1 is synthesized according to the free radical polymerization route, and free radicals are provided by thermal decomposition of perfluorobenzoyl peroxide PFDBPO.

[0067] S101: Add n moles of monomer M8A: perfluoro-2-methyl-4,5-methyl ether group-1,3-dioxolane, m moles of monomer M8C: perfluoro-2- Methyl-4-ethyl-1,3-dioxolane, initiator, wherein n:m=20-95:5-80; the initiator includes perfluorodibenzoyl peroxide, the initiator The mass percentage is 0.1%;

[0068] That is, in a small reactor with good airtightness, add 258.4 grams (0.95mol) of M8A monomer and 14.7 grams (0.05mol) of M8C monomer, and then add 0.273 grams of initiator;

[0069] S102: Stir and clean with nitrogen gas. After cleaning, the reactor is depressurized to 0.3-0.8 atmospheric pressure, and heated to 70-90°C for polymerization reaction. The reaction time is 25-35h;

[0070] In this embodiment, the reaction pressure of t...

Embodiment 2

[0074] Such as image 3 As shown, the synthesis of copolymer F2

[0075] Copolymer F2 is synthesized according to the free radical polymerization route, and free radicals are provided by thermal decomposition of perfluorodibenzoyl peroxide PFDBPO.

[0076] The difference between the present embodiment and the first embodiment is: the molar mass of the M8A monomer and the M8C monomer. In this embodiment, the M8A monomer is 217.6 grams (0.8 mol), the M8C monomer is 18.8 grams (0.2 mol), and the initiator is 0.236 grams After the polymerization reaction, the copolymer F2 is obtained, and the conversion rate of the copolymer F2 is calculated to be 79%, and the thermogravimetric analysis method TGA is used to record the thermal decomposition temperature Td of the copolymer F2 in air ≥ 300 ° C, indicating that the copolymerization Material F2 has high thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com