Lithium battery negative plate loaded with temperature-resistant composite layer and preparation method

A technology for negative pole pieces and lithium batteries, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as thermal runaway and lithium battery thermal runaway, and achieve improved temperature resistance, good safety and usability, The effect of high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

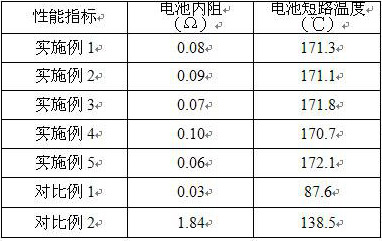

Examples

Embodiment 1

[0042] (1) Mix 90kg of carbon material, 2.5kg of polyvinylidene fluoride, and 3kg of Super-P evenly, prepare a slurry, and then coat it on the surface of copper foil, then dry it, collect it, and obtain the negative electrode sheet;

[0043] (2) Add 15kg of polyvinylidene fluoride-hexafluoropropylene copolymer into 40kg of acetone and 60kg of N,N-dimethylformamide mixed solvent, then stir at 345°C for 75 minutes until completely dissolved to obtain a mixed solution;

[0044] (3) Put 22kgLi 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , 3kg of polyethylene oxide, and 2kg of graphene oxide powder were added to 125 kg of the obtained mixed solution to configure suspension A, then the suspension A was stirred at 65°C for 1.5 hours, and then sprayed on the surface of the negative electrode sheet under high pressure , and then dried in a vacuum oven for 35 minutes to remove the solvent to obtain a negative electrode sheet with a porous conductive layer with an average film thickness of 25 μm;...

Embodiment 2

[0047] (1) Mix 85kg of silicon-carbon composite material, 3kg of polyvinylidene fluoride, and 4kg of Super-P evenly, prepare a slurry, and then coat it on the surface of copper foil, then dry it, collect it, and obtain the negative electrode sheet;

[0048] (2) Add 13kg of polyvinylidene fluoride-hexafluoropropylene copolymer into 35kg of acetone and 65kg of N,N-dimethylformamide mixed solvent, then stir at 40°C for 90 minutes until completely dissolved to obtain a mixed solution;

[0049] (3) Put 20kgLi 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , 2kg polyethylene oxide, and 1.5kg graphene oxide powder were added to 140 kg of the obtained mixed solution, and configured as suspension A, then the suspension A was stirred at 60°C for 2 hours, and then sprayed on the surface of the negative electrode sheet under high pressure , and then dried in a vacuum oven for 32 minutes to remove the solvent to obtain a negative electrode sheet with a porous conductive layer with an average film thic...

Embodiment 3

[0052] (1) Mix 95kg of carbon material, 2kg of polyvinylidene fluoride, and 2kg of Super-P evenly, prepare a slurry, and then coat it on the surface of copper foil, then dry it, collect it, and obtain the negative electrode sheet;

[0053] (2) Add 18kg of polyvinylidene fluoride-hexafluoropropylene copolymer into 45kg of acetone and 55kg of N,N-dimethylformamide mixed solvent, and then stir at 50°C for 60 minutes until completely dissolved to obtain a mixed solution;

[0054] (3) Put 25kgLi 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , 4kg of polyethylene oxide, and 2.5kg of graphene oxide powder were added to 110 kg of the obtained mixed solution to form a suspension A, then the suspension A was stirred at 70°C for 1 hour, and then sprayed on the surface of the negative electrode sheet under high pressure , and then dried in a vacuum oven for 38 minutes to remove the solvent to obtain a negative electrode sheet with a porous conductive layer with an average film thickness of 28 μm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com