Lithium ion battery negative electrode polymer binder and preparation method and application thereof

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle performance deterioration, loss of electrical contact, volume change, etc., to improve cycle stability and maintain structural stability , enhance the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

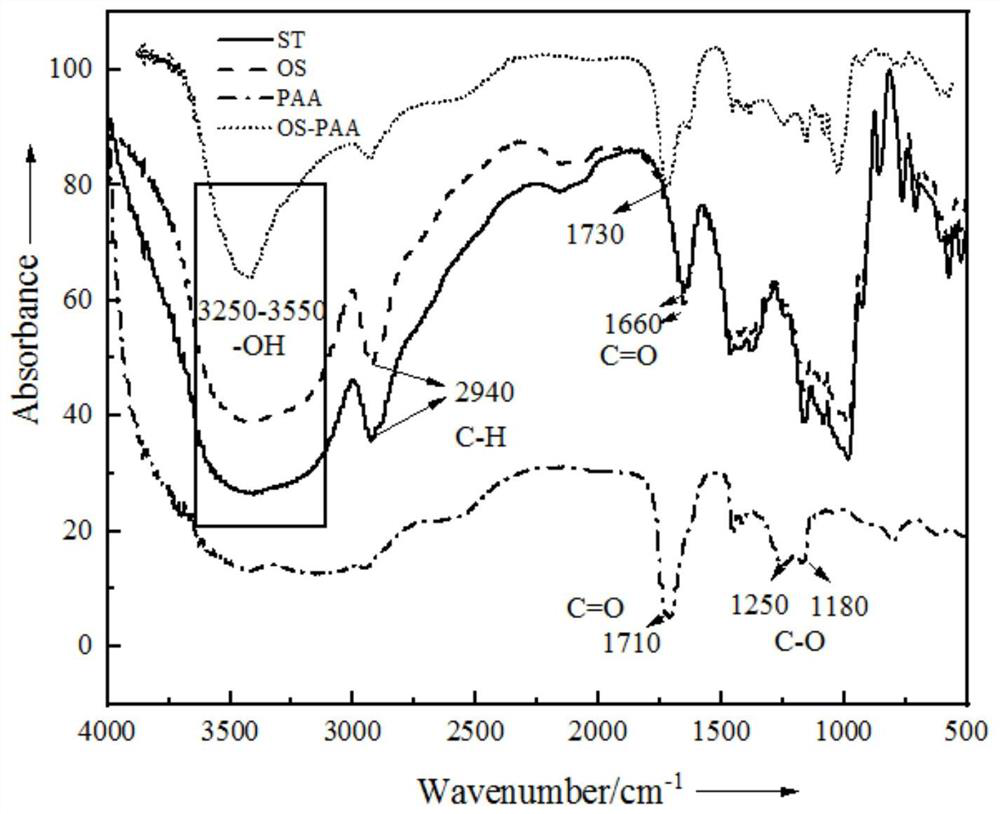

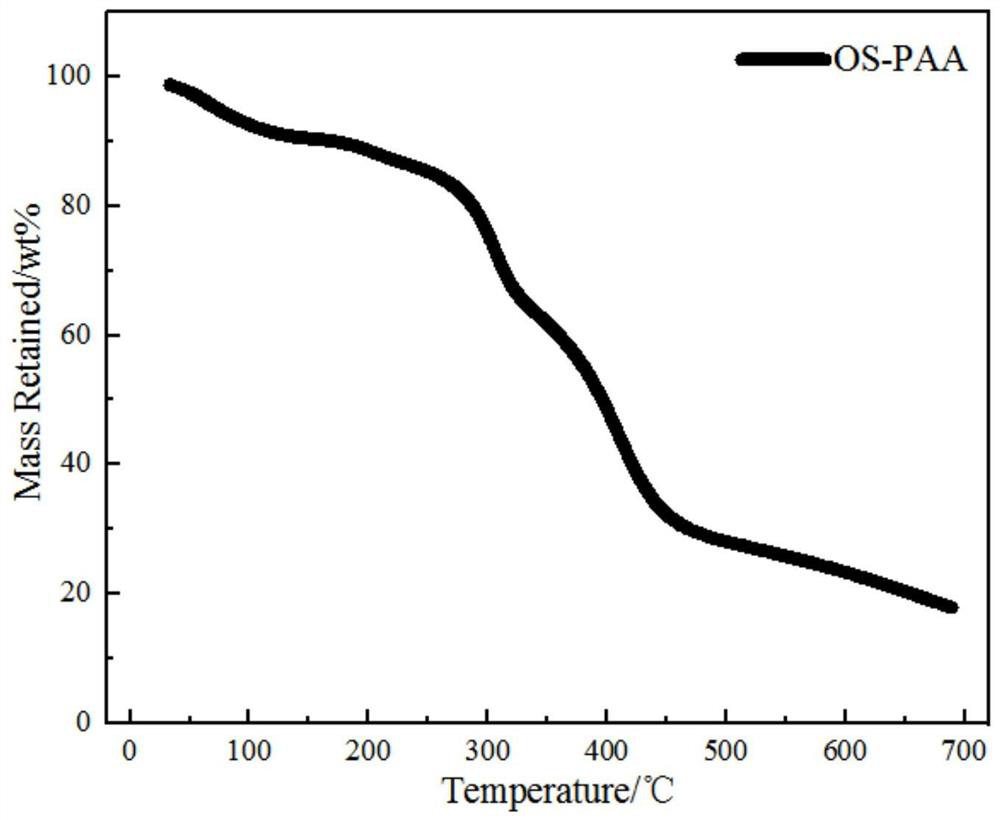

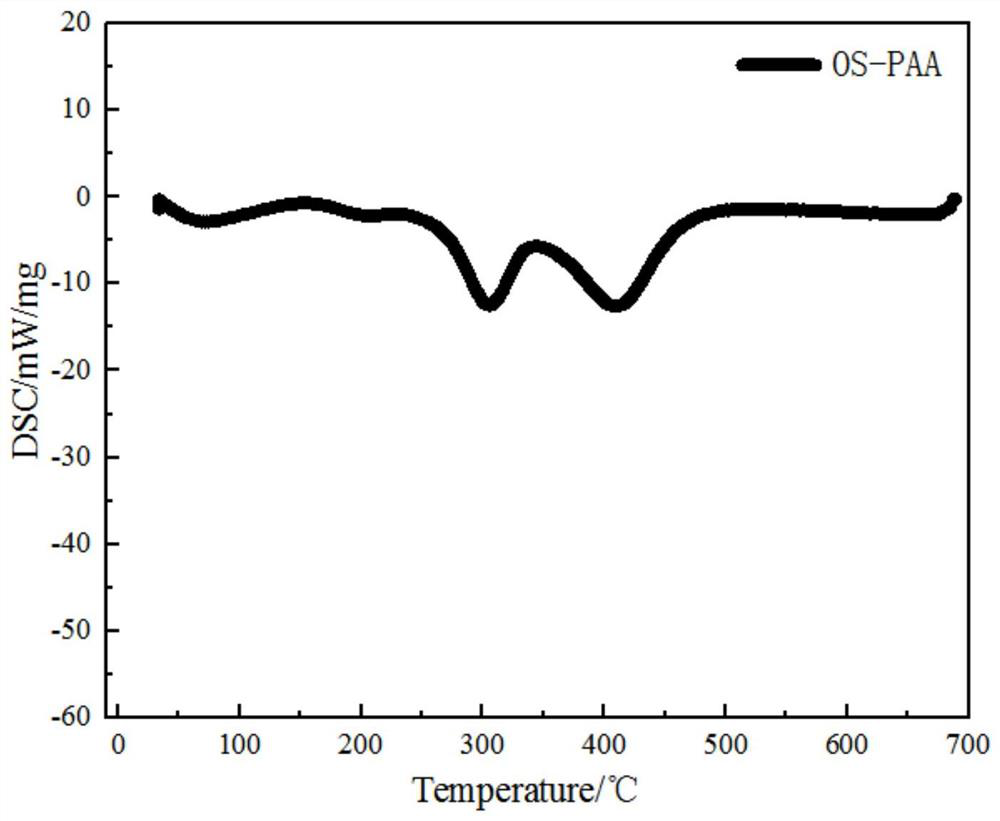

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of preparation method of polymer binder, and it comprises the following steps:

[0039] a. Add 10 g of starch to 40 mL of deionized water, stir with a magnetic stirrer for 10 min, add 5% NaOH dropwise, adjust the pH to 8, and adjust the temperature of the water bath to 40°C.

[0040] b. Add 0.001g of anhydrous copper sulfate, slowly add 4mL of 30% hydrogen peroxide dropwise, react at a water bath temperature of 40°C for 30min, then add 0.02g of sodium bisulfite, and stir for 10 minutes. Slowly add 5% dilute hydrochloric acid dropwise to adjust the pH of the solution to 5.5-6.0. Suction filtration and dehydration, wash with deionization, put into oven, drying temperature is 40°C, and dry for 6h. The solid was pulverized and ground to obtain a solid powder.

[0041] c. Put 1g of oxidized starch into a three-necked flask, add 50mL of deionized water, stir for 2h, then add 1g of polyacrylic acid, under the protection of Ar gas, adjus...

Embodiment 2

[0049] This example provides a preparation method of the negative electrode binder for lithium ion batteries, which is basically the same as that in Example 1, except that in step (a), the alkaline pH is set to 7.

Embodiment 3

[0051] This example provides a method for preparing a negative electrode binder for lithium ion batteries, which is basically the same as that in Example 1, except that the alkaline pH in step (a) is set to 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com