A noble metal single-atom catalyst for electrolysis of water and oxygen evolution, its preparation method and application

A technology of precious metals and electrolysis of water, applied in chemical instruments and methods, physical/chemical process catalysts, electrolytic components, etc., can solve problems such as poor stability, agglomeration of precious metal elements, weak interaction, etc., to achieve tight combination and improve catalytic reaction kinetics Learning and promoting the effect of electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Dissolve the following raw materials in deionized water, mix well, and prepare stock solution:

[0061] Ferric Nitrate Nonahydrate 0.12%

[0062] Nickel nitrate hexahydrate 0.09%

[0063] Thiourea 0.025%

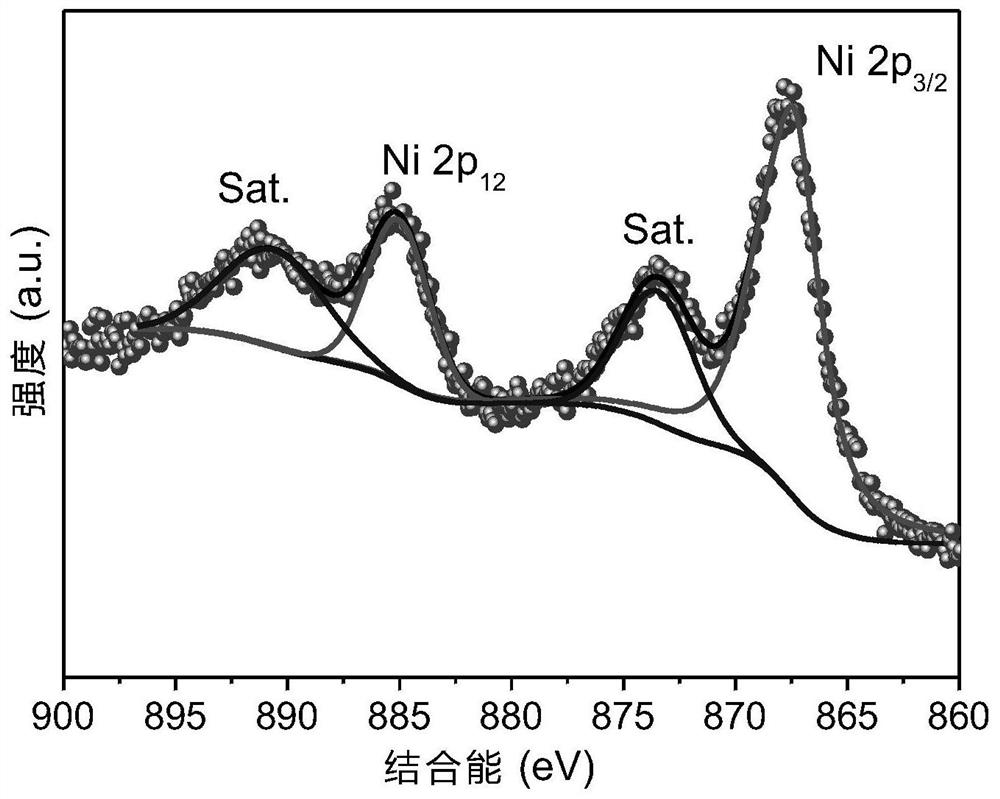

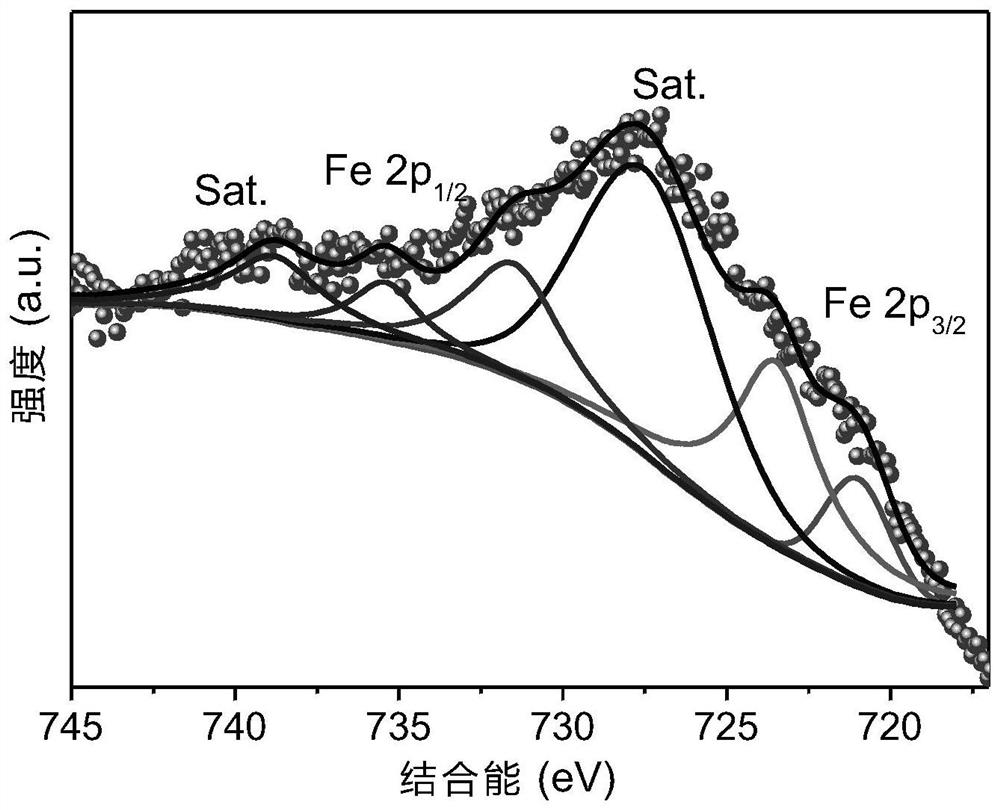

[0064] (2) Take a part of the stock solution and add iridium trichloride hydrate with a mass percentage ratio of 0.018% to prepare an electrosorption solution for preparing a sulfide catalyst supporting monoatomic iridium.

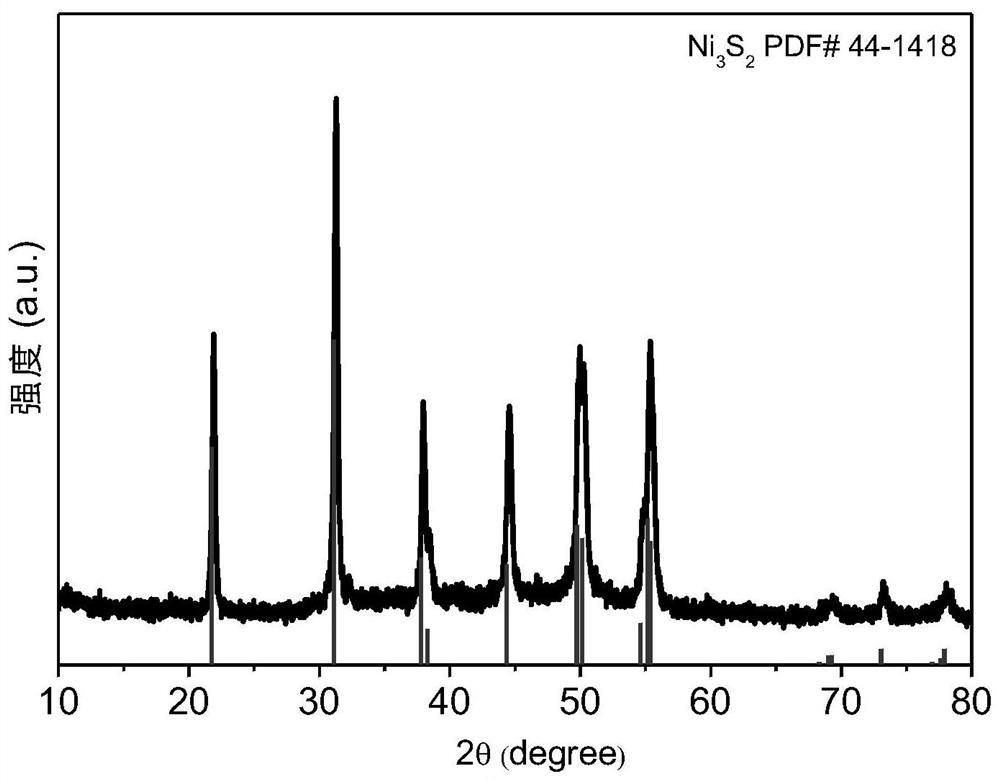

[0065] (3) With nickel foam as the working electrode, carbon rod as the counter electrode, and Hg / HgO electrode as the reference electrode, put it into the stock solution prepared in step (1), and electrodeposit it by cyclic voltammetry, and the scanning range is -1.2V ~0.2V, scan rate is 10mV / s, cycle number is 6 times. Deposition of nickel iron sulfide substrates on nickel foam.

[0066] (4) With the nickel-iron sulfide substrate prepared in step (3) as the working electrode, the carbon rod as the counter electrode, and the Hg / HgO electr...

Embodiment 2

[0069] (1) Dissolve the following raw materials in deionized water, mix well, and prepare stock solution:

[0070] Ferric chloride hexahydrate 0.12%

[0071] Nickel chloride hexahydrate 0.09%

[0072] Thiourea 0.025%

[0073] (2) Take a part of the stock solution and add iridium trichloride hydrate with a mass percentage ratio of 0.018% to prepare an electrosorption solution for preparing a sulfide catalyst supporting monoatomic iridium.

[0074] (3) With nickel foam as the working electrode, carbon rod as the counter electrode, and Hg / HgO electrode as the reference electrode, put it into the stock solution prepared in step (1), and electrodeposit it by cyclic voltammetry, and the scanning range is -1.2V ~0.2V, scan rate is 10mV / s, cycle number is 6 times. Deposition of nickel iron sulfide substrates on nickel foam.

[0075] (4) With the nickel-iron sulfide substrate prepared in step (3) as the working electrode, the carbon rod as the counter electrode, and the Hg / HgO elec...

Embodiment 3

[0078] (1) Dissolve the following raw materials in deionized water, mix well, and prepare stock solution:

[0079] Ferric Nitrate Nonahydrate 0.5%

[0080] Nickel nitrate hexahydrate 0.4%

[0081] Thiourea 0.1%

[0082] (2) Take a part of the stock solution and add iridium trichloride hydrate with a mass percentage ratio of 0.018% to prepare an electrosorption solution for preparing a sulfide catalyst supporting monoatomic iridium.

[0083] (3) With nickel foam as the working electrode, carbon rod as the counter electrode, and Hg / HgO electrode as the reference electrode, put it into the stock solution prepared in step (1), and electrodeposit it by cyclic voltammetry, and the scanning range is -1.2V ~0.2V, scan rate is 10mV / s, cycle number is 6 times. Deposition of nickel iron sulfide substrates on nickel foam.

[0084] (4) With the nickel-iron sulfide substrate prepared in step (3) as the working electrode, the carbon rod as the counter electrode, and the Hg / HgO electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com