Preparation method of N-doped graphene/graphene nanobelt composite aerogel

A graphene nanoribbon and composite airgel technology, applied in the field of composite materials, can solve the problems of high cost, complicated preparation process, and inability to obtain commercial application, achieve high porosity, simple preparation process, and reduce agglomeration force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

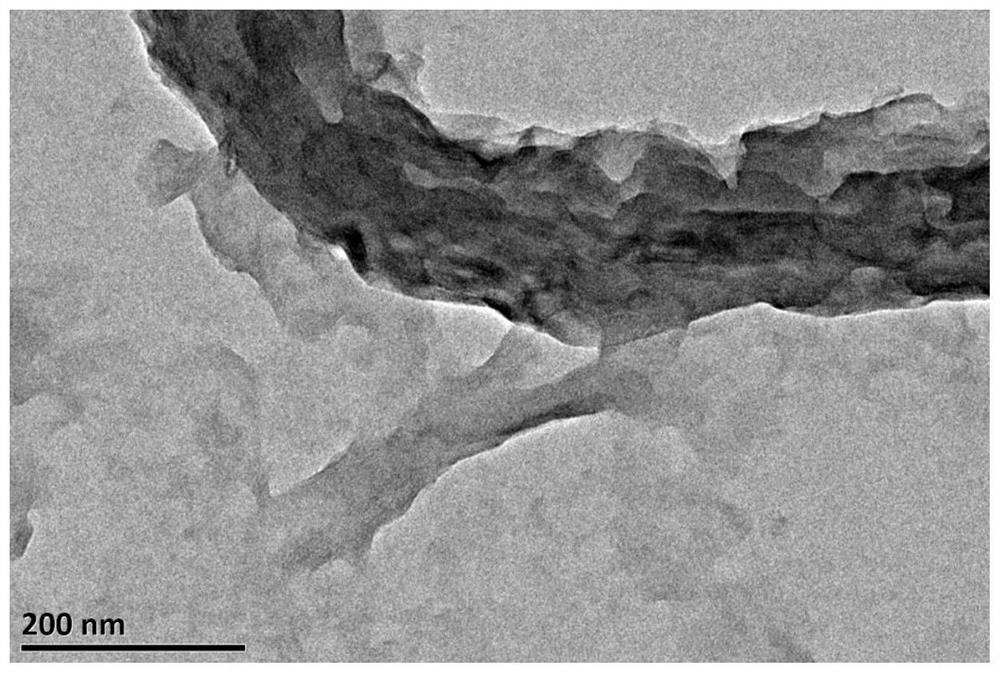

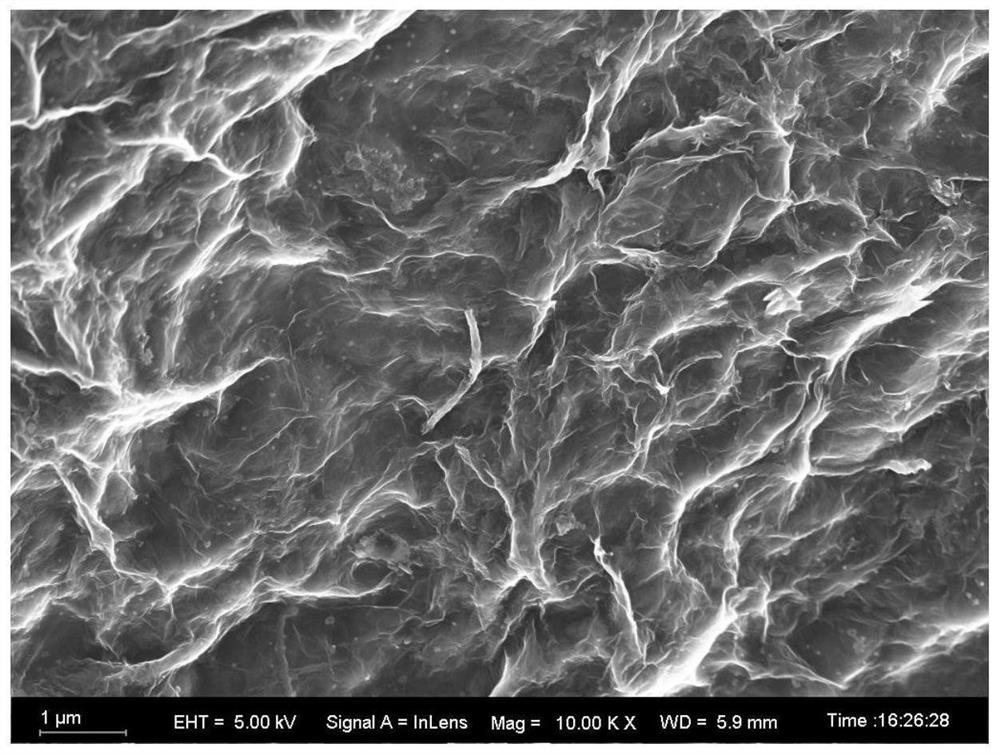

[0029] Specific embodiment one: what this embodiment records is a kind of preparation method of N-doped graphene / graphene nanoribbon composite airgel, described method comprises the following steps:

[0030] Step 1: preparing a graphene oxide dispersion and a graphene oxide nanoribbon dispersion with a concentration ≥ 10 mg / ml;

[0031] Step 2: Pre-reduction to construct a three-dimensional skeleton: Dilute the two dispersions obtained in Step 1 to 10 mg / ml, mix them with a reducing agent, pour them into a molding mold and heat and reduce them in a closed environment to obtain a sol;

[0032] Step 3: freezing and strengthening the three-dimensional porous network structure: transfer the sol obtained in step 2 into a freezer for rapid freezing and shaping;

[0033] Step 4: Thawing: Take out the sample in Step 3 together with the forming mold and heat and thaw it on the heating table. After the ice crystals completely disappear, the composite hydrogel is obtained;

[0034] Step...

specific Embodiment approach 2

[0036] Specific embodiment two: the preparation method of the N-doped graphene / graphene nanoribbon composite aerogel described in specific embodiment one, in step one, described graphene oxide dispersion liquid is by putting graphite in concentrated sulfuric acid, phosphoric acid The mixture is synthesized by reacting with potassium permanganate; the graphene oxide nanoribbon dispersion is obtained by longitudinally cutting carbon nanotubes. The advantage is that the prepared graphene oxide and nanobelts are rich in oxygen-containing functional groups, which play a positive role in the preparation and performance of materials.

specific Embodiment approach 3

[0037] Specific embodiment three: the preparation method of N-doped graphene / graphene nanoribbon composite aerogel described in specific embodiment one, described step two is specifically: the two kinds of dispersion liquids that step one obtains are diluted to 10mg respectively / ml Mix and stir at the speed of 100-3000r / min for 10-1200min; after adding the reducing agent, stir at a high speed of 100-3000r / min for 1-24h, then ultrasonically disperse at the frequency of 50KHz for 1-24h, and repeat the stirring and ultrasonic operation for 1-5 times; finally, pour the mixed liquid into a molding mold and heat and reduce it in a closed environment to form a sol with a three-dimensional porous network structure. The advantages are: through repeated stirring and ultrasonic waves, graphene oxide nanoribbons can be evenly distributed between graphene oxide sheets to play a good barrier effect, effectively avoid graphene agglomeration, and facilitate the overlapping of three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com