Graphene glass and preparation method thereof

A graphene and graphene layer technology, applied in coatings and other directions, can solve the problems of influence, metal pollution, influence on the light transmittance performance of graphene glass, etc., and achieve the effects of excellent surface resistance, low surface resistance, and uniform number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]The preparation method of the present invention may also include other auxiliary steps, such as performing plasma treatment on the glass substrate to clean the surface of the glass substrate before chemical vapor deposition. The plasma treatment is to use oxygen plasma to treat the glass substrate, the amount of oxygen introduced is 1-100sccm, the power is 10-500W, and the treatment time is 1min-15min.

[0029] The glass substrate used in the present invention may be quartz glass, sapphire glass, high boron glass, high alumina glass or borosilicate glass.

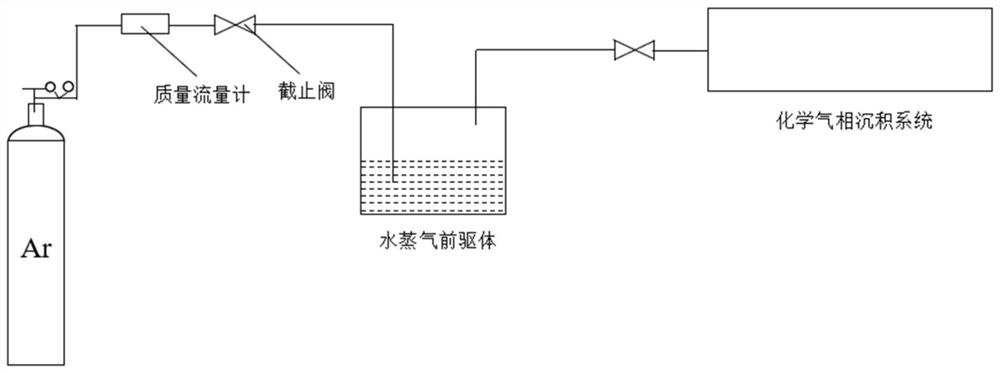

Embodiment 1

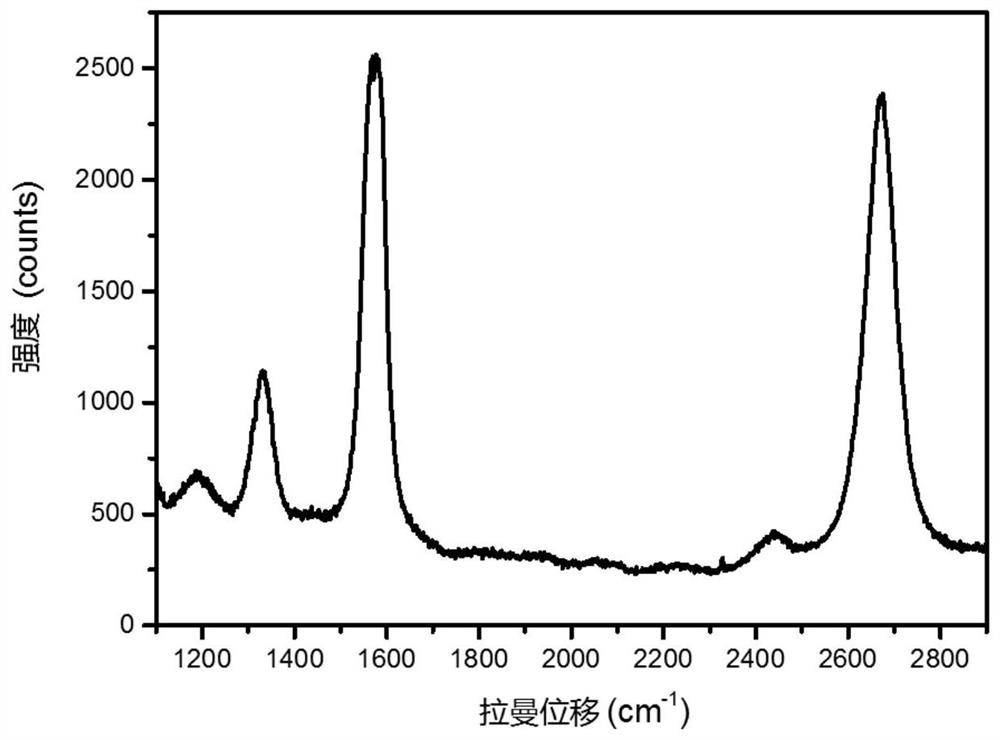

[0033] The glass substrate is ultrasonically treated with deionized water, ethanol, and acetone in sequence, wherein the glass substrate is quartz glass. Put the cleaned quartz glass into the plasma equipment, set the power of the plasma equipment to 60W, and treat with oxygen plasma for 10 minutes. Vapor deposition process, see figure 1 . First, put the treated quartz glass substrate into the quartz tube of the tube furnace, heat it under the air atmosphere, evacuate to 0pa, open the argon flow valve and let the argon gas into the normal pressure, and finally carry out the chemical vapor deposition process. The chemical vapor deposition atmosphere is a mixed gas of methane, hydrogen, argon, and methanol vapor. The gas flow rate of methane is 10 sccm, the gas flow rate of hydrogen gas is 260 sccm, and the gas flow rate of argon gas is 600 sccm. The gas flow rate is 50 sccm, the gas deposition temperature is 1100° C., and the growth time is 420 min. Take out the grown graphe...

Embodiment 2

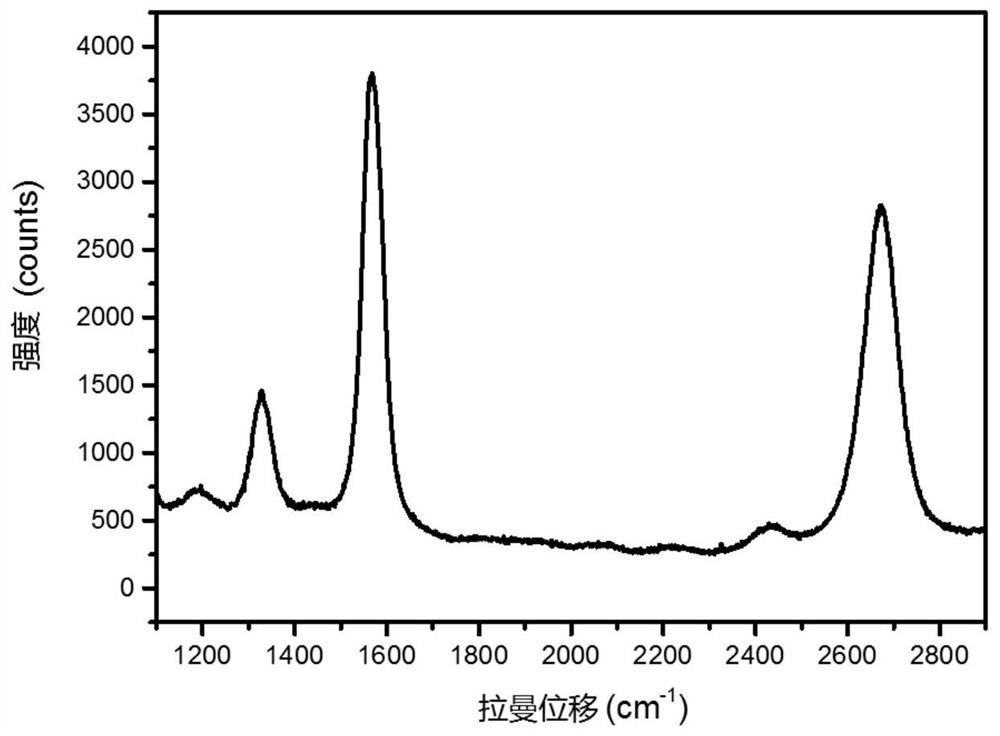

[0035] Prepare according to the method for Example 1, the difference is that the gas flow of methane is 50 sccm, the gas flow of hydrogen is 260 sccm, the gas flow of argon is 600 sccm, and the argon flow used in methanol is passed into by bubbling method is 30 sccm; The deposition temperature is 1100°C, and the growth time is 420min. The finally obtained graphene glass has a transmittance of 82.1% and a surface resistance of 786Ω / sq.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com