A kind of three-dimensional porous lactose particle and its preparation method and application

A three-dimensional porous, lactose technology, applied in the field of medicine, can solve the problems of unfavorable scale-up production, low yield, residual ammonia or sodium ions, etc., achieve good fluidity and uniformity, uniform particle size distribution, and improve wall sticking phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

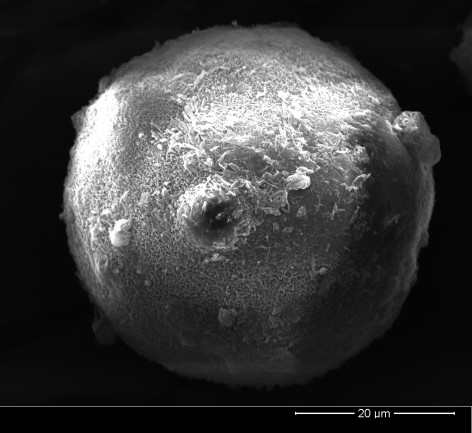

[0035] Take lactose and povidone K30 with a weight ratio of 10:1, mix lactose, povidone K30 and water to form a solution with a solid content of 12%, and spray dry to make composite particles. The conditions for spray drying are: air intake The temperature is 140°C, the air outlet temperature is 80°C, and the material pumping speed is 6mL / min; after mixing 50g of the obtained composite particles and 300mL of absolute ethanol, stir magnetically at a speed of 300r / min for 12h, centrifuge, and remove the supernatant The precipitate was obtained, blown and dried to constant weight at 60° C. to obtain three-dimensional porous lactose particles, and the obtained three-dimensional porous lactose particles were tested by scanning electron microscope, and the test results were as follows: figure 1 shown, and tested the fluidity (Carr index, Housen ratio and angle of repose), particle size distribution (uniformity), and yield of three-dimensional porous lactose particles. The test result...

Embodiment 2

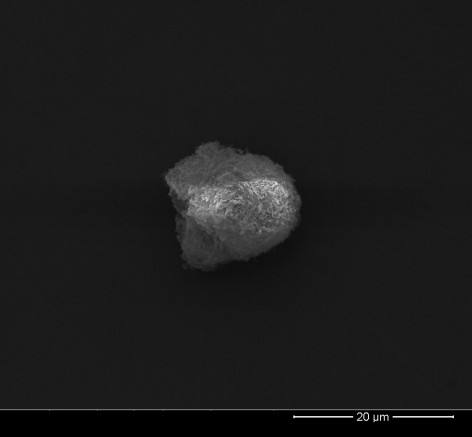

[0038] Three-dimensional porous lactose particles were prepared using a preparation method similar to that of Example 1. The difference between this example and Example 1 is that the weight ratio of lactose and povidone K30 is different. In this example, lactose and povidone K30 The weight ratio of the obtained three-dimensional porous lactose particles is 10:2; the scanning electron microscope test is carried out to the obtained three-dimensional porous lactose particles, and the test results are as follows figure 2 shown, and tested the fluidity (Carr index, Housen ratio and angle of repose), particle size distribution (uniformity), and yield of three-dimensional porous lactose particles. The test results are shown in Table 1; drug powder, and determine the active ingredient content and dissolution behavior of the drug-loaded powder, and evaluate its drug release behavior. The measurement results are as follows: Figure 6 Shown in the S2 curve.

Embodiment 3

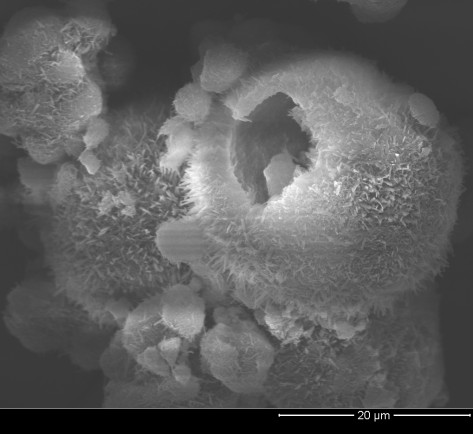

[0040] Three-dimensional porous lactose particles were prepared using a preparation method similar to that of Example 1. The difference between this example and Example 1 is that the weight ratio of lactose and povidone K30 is different. In this example, lactose and povidone K30 The weight ratio of the obtained three-dimensional porous lactose particles is 10:3; the scanning electron microscope test is carried out to the obtained three-dimensional porous lactose particles, and the test results are as follows: image 3 shown, and tested the fluidity (Carr index, Housen ratio and angle of repose), particle size distribution (uniformity), and yield of three-dimensional porous lactose particles. The test results are shown in Table 1; drug powder, and determine the active ingredient content and dissolution behavior of the drug-loaded powder, and evaluate its drug release behavior. The measurement results are as follows: Figure 6 Shown in the S3 curve in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com