Reusable mask fabric and preparation method thereof

A mask and fabric technology, applied in the field of medical and sanitary products, can solve the problem that disposable masks cannot be reused, achieve good antibacterial and antiviral performance, ensure mechanical strength, and optimize the effect of filtering effect indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

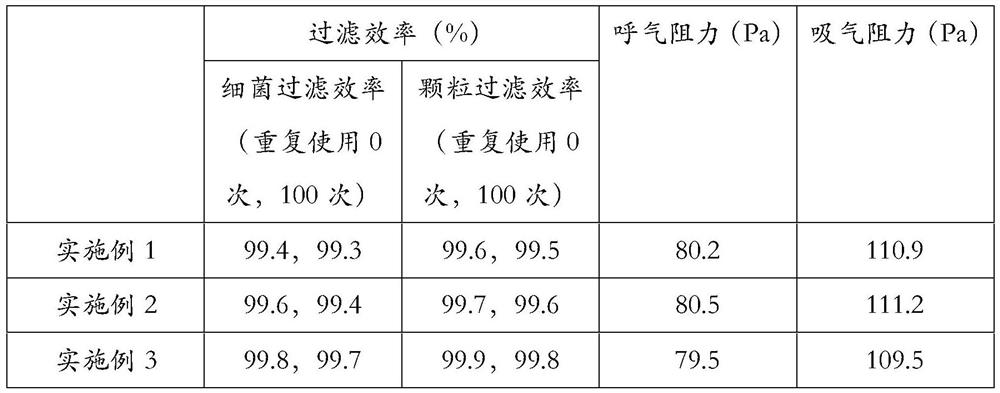

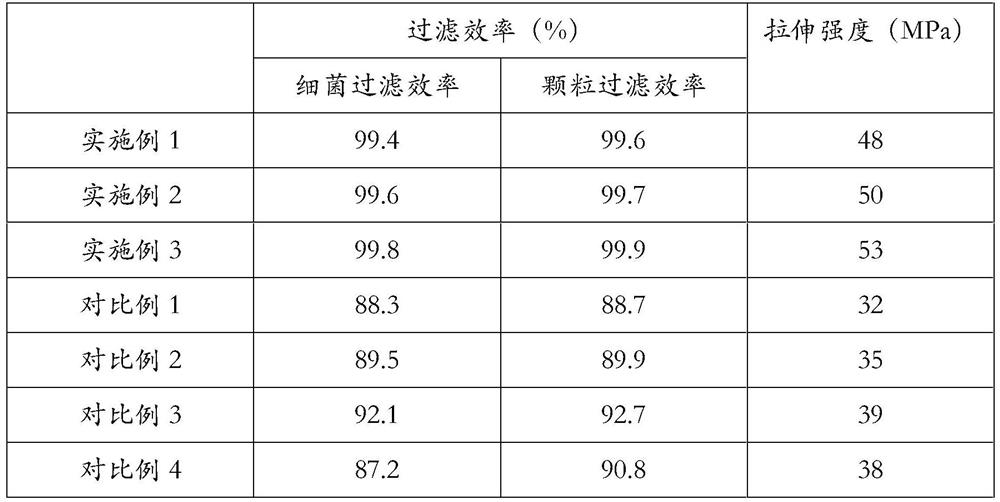

Examples

Embodiment 1

[0040] A kind of preparation method of reusable mask fabric, first add 10kg polyvinylidene fluoride resin powder, 2kg polyurethane powder, 0.1kg nanometer powder, 0.3kg liquid polyacrylonitrile to 8kg containing 1-butyl-3-methylimidazole In the graphene oxide aqueous solution of bis(trifluoromethanesulfonyl)imide salt, the ultrasonic vibration is uniform to obtain a paste material, and then the paste material is pushed, calendered, microwave foamed, stretched, sintered, and reduced, that is Obtain the mask fabric; wherein, the nano-powder is first made into a gel with melamine-formaldehyde resin, tetrabutyl titanate and nano-yttrium oxide as raw materials, and then hydrothermally reacted.

[0041]The liquid polyacrylonitrile is a copolymer of acrylonitrile and methyl methacrylate, the monomer ratio is 1:0.6, and the relative molecular weight of the liquid polyacrylonitrile is 10000.

[0042] The graphene oxide aqueous solution containing 1-butyl-3-methylimidazole bis(trifluoro...

Embodiment 2

[0059] A kind of preparation method of reusable mask fabric, first add 10kg polyvinylidene fluoride resin powder, 3kg polyurethane powder, 0.08kg nanometer powder, 0.5kg liquid polyacrylonitrile to 6kg containing 1-butyl-3-methylimidazole In the graphene oxide aqueous solution of bis(trifluoromethanesulfonyl)imide salt, the ultrasonic vibration is uniform to obtain a paste material, and then the paste material is pushed, calendered, microwave foamed, stretched, sintered, and reduced, that is Obtain the mask fabric; wherein, the nano-powder is first made into a gel with melamine-formaldehyde resin, tetrabutyl titanate and nano-yttrium oxide as raw materials, and then hydrothermally reacted.

[0060] The liquid polyacrylonitrile is a copolymer of acrylonitrile and methyl methacrylate, the monomer ratio is 1:0.6, and the relative molecular weight of the liquid polyacrylonitrile is 15,000.

[0061] The graphene oxide aqueous solution containing 1-butyl-3-methylimidazole bis(triflu...

Embodiment 3

[0078] A kind of preparation method of reusable mask fabric, first add 10kg polyvinylidene fluoride resin powder, 2.5kg polyurethane powder, 0.09kg nano powder, 0.4kg liquid polyacrylonitrile to 7kg containing 1-butyl-3-methyl In the graphene oxide aqueous solution of imidazole bis(trifluoromethanesulfonyl)imide salt, ultrasonically oscillate evenly to obtain a paste material, and then push the paste material, calender, microwave foaming, stretching, sintering, reduction, The mask fabric is obtained; wherein, the nano-powder is first made into a gel with melamine-formaldehyde resin, tetrabutyl titanate and nano-yttrium oxide as raw materials, and then hydrothermally reacted.

[0079] The liquid polyacrylonitrile is a copolymer of acrylonitrile and methyl methacrylate, the monomer ratio is 1:0.6, and the relative molecular weight of the liquid polyacrylonitrile is 13000.

[0080] The graphene oxide aqueous solution containing 1-butyl-3-methylimidazole bis(trifluoromethanesulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com