Collagen lamellar matrix material, preparation method and application thereof

A technology of matrix material and collagen layer, which is used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor biocompatibility of artificial synthetic materials, unable to meet the requirements of surgical suture, affecting transparency and mechanical strength, etc. Or the effect of restoring vision, excellent biocompatibility, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

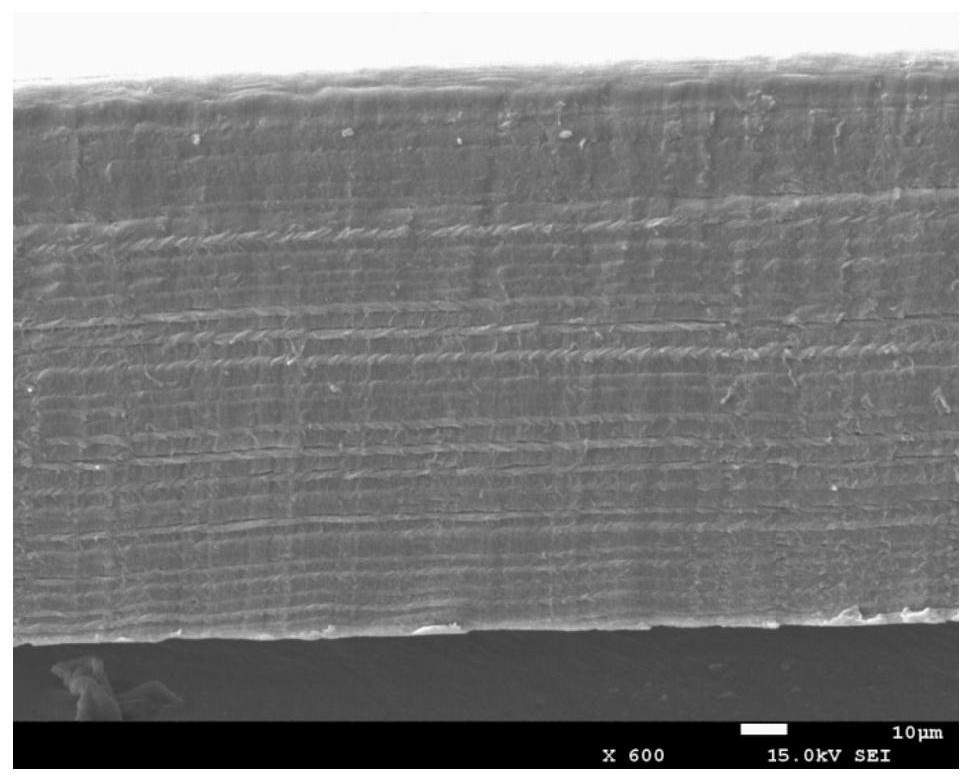

[0039] A preferred embodiment of the present invention provides a method for preparing a collagen lamellar matrix material, the specific steps are as follows:

[0040] Spread the decalcified fish scales on the bottom plate with holes, each hole of the bottom plate corresponds to a sample, start the vacuum device to make the samples adsorb on the bottom plate, and select a partition with a suitable pore size to spread on the fish scale sample as required. Spray the etchant evenly on the surface of the decalcified fish scales and let it stand. At regular intervals, spray cleaning solution to wash off the etching solution on the surface of fish scales, and then spray new etching solution again. Different partitions were replaced during the etching process to ensure that the etching time for the middle part of the sample reached 17 hours, and the etching time for the edge part reached 8 hours. After the etching is completed, rinse with ultrapure water for 3 times, each time for 1...

Embodiment 2

[0047] A preferred embodiment of the present invention provides a method for preparing a collagen lamellar matrix material, the specific steps are as follows:

[0048] Spread the decalcified fish scales on the bottom plate with holes, each hole of the bottom plate corresponds to a sample, start the vacuum device to make the samples adsorb on the bottom plate, and select a partition with a suitable pore size to spread on the fish scale sample as required. Spray the etchant evenly on the surface of the decalcified fish scales and let it stand. At regular intervals, spray cleaning solution to wash off the etching solution on the surface of fish scales, and then spray new etching solution again. Different partitions were replaced during the etching process to ensure that the etching time for the middle part of the sample reached 18 hours, and the etching time for the edge part reached 9 hours. After the etching is completed, rinse with ultrapure water for 3 times, each time for 1...

Embodiment 3

[0053] A preferred embodiment of the present invention provides a method for preparing a collagen lamellar matrix material, the specific steps are as follows:

[0054] Spread the decalcified fish scales on the bottom plate with holes, each hole of the bottom plate corresponds to a sample, start the vacuum device to make the samples adsorb on the bottom plate, and select a partition with a suitable pore size to spread on the fish scale sample as required. Spray the etchant evenly on the surface of the decalcified fish scales and let it stand. At regular intervals, spray cleaning solution to wash off the etching solution on the surface of fish scales, and then spray new etching solution again. Different partitions were replaced during the etching process to ensure that the etching time for the middle part of the sample reached 19 hours, and the etching time for the edge part reached 8 hours. After the etching is completed, rinse with ultrapure water for 3 times, each time for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

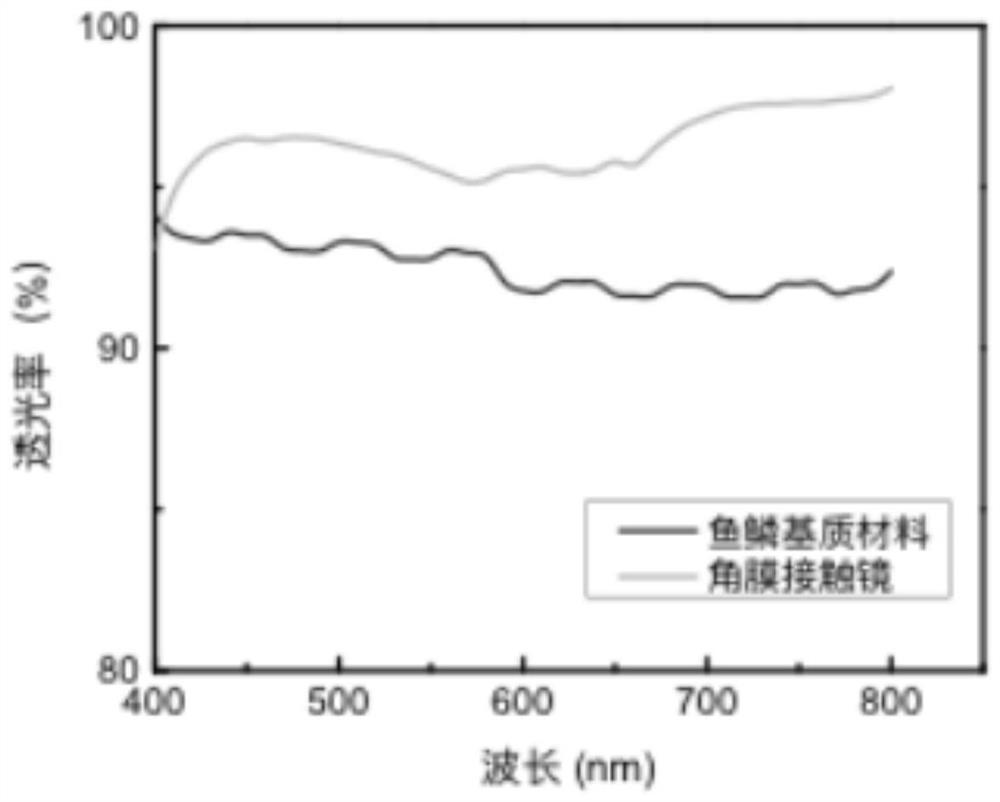

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com