Preparation method and application of magnesium titanate/graphite-phase carbon nitride composite visible light photocatalyst

A graphite-phase carbon nitride and magnesium titanate technology, which is applied in the field of photocatalysis, can solve the problems of poor performance of visible light catalytic hydrogen production, small specific surface area, high photogenerated electron-hole recombination rate, and achieve high utilization rate of visible light, The effect of a wide range of visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

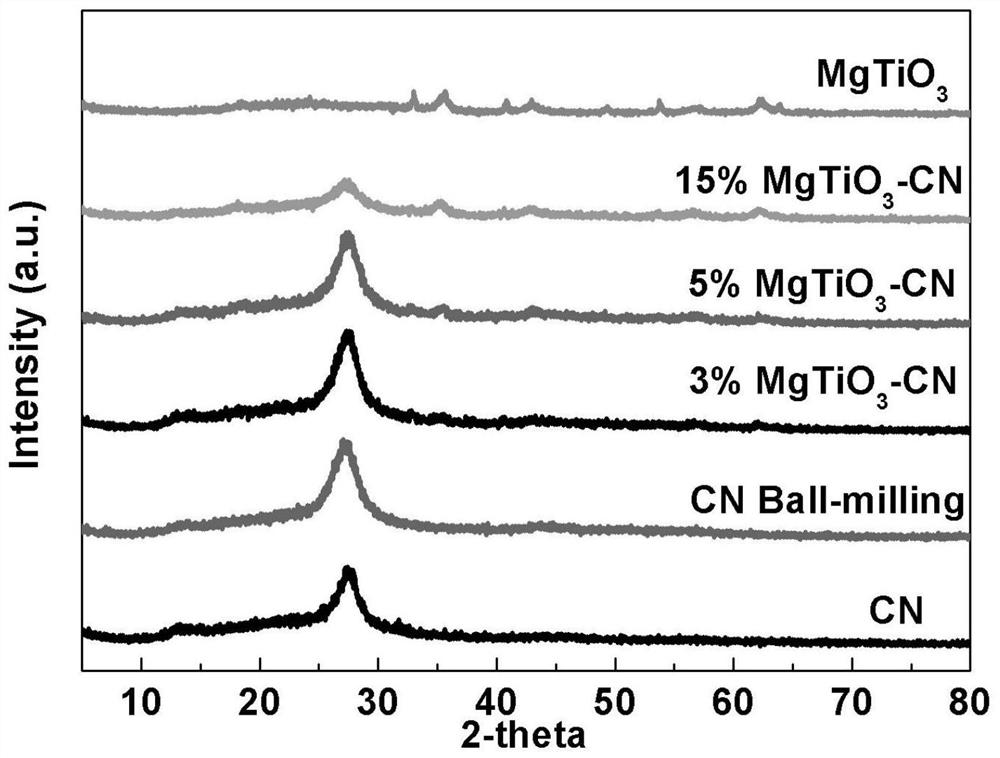

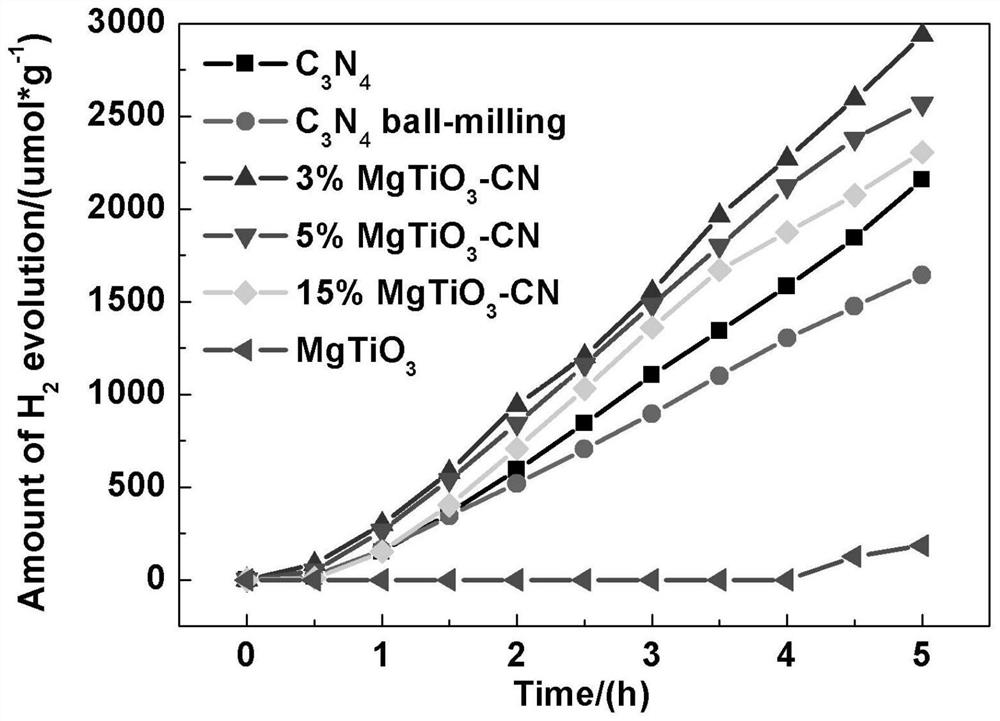

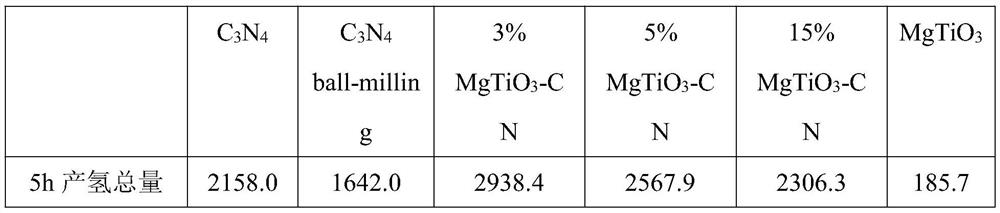

Embodiment 1

[0025] Step 1. Preparation of graphite phase carbon nitride powder: Weigh 20.000g of urea and grind it evenly into a crucible, cover the crucible and put it in a muffle furnace for calcination. The calcination process is as follows: from Heating at room temperature to 520°C, then keeping it warm at this temperature for 2 hours, cooling to room temperature naturally and grinding thoroughly to obtain graphite phase carbon nitride powder, denoted as C3N4;

[0026] Step 2. Preparation of perovskite magnesium titanate powder: Weigh 6.434g magnesium acetate tetrahydrate and place it in a beaker, measure 60.0mL ethylene glycol and add it to the weighed magnesium acetate tetrahydrate, use a 5.0mL pipette Add 3.4mL tetrabutyl titanate to the above solution, place it on a magnetic stirrer at room temperature and stir for 30 minutes, then put it into a reaction kettle, put the reaction kettle in an oven and heat it at 180±5°C for 24 hours, take it out and centrifuge it, and use it after c...

Embodiment 2

[0028] Embodiment 2: The difference from Example 1 is: in step 3, 0.025g of perovskite-type magnesium titanate powder is weighed, and the obtained magnesium titanate / graphite phase carbon nitride composite visible light catalyst is recorded as 5%MgTiO3 / g-CN.

Embodiment 3

[0029] Embodiment 3: The difference from Example 1 is: in step 3, 0.075g of perovskite-type magnesium titanate powder is weighed, and the obtained magnesium titanate / graphite phase carbon nitride composite visible light catalyst is recorded as 15%MgTiO3 / g-CN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com