Preparation method of 1,2,4,5-tetramethylbenzene

A technology of durene and tetramethylbenzene, which is applied in the field of preparation of high-purity durene, which can solve the problems of polluting process, immaturity, and incapability of large-scale production, and achieve the effect of simple separation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

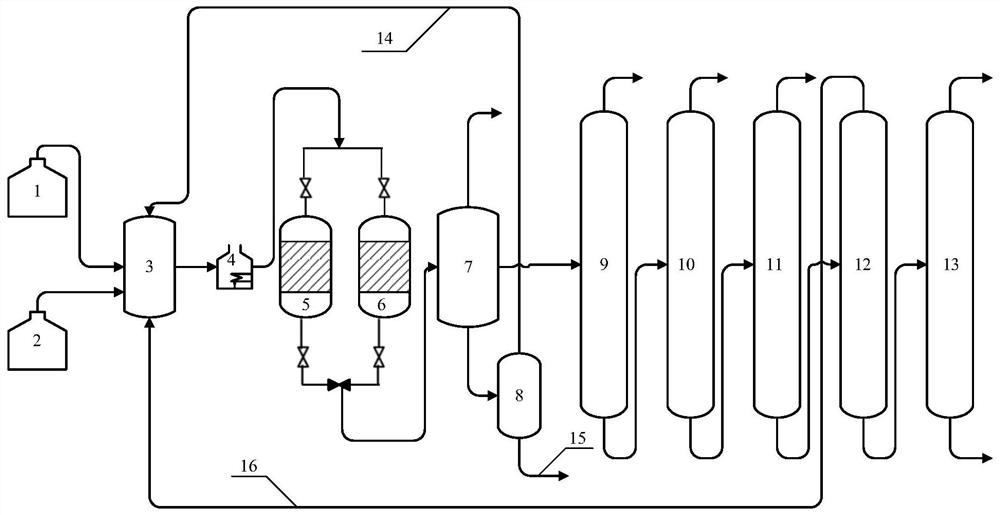

Image

Examples

preparation example Construction

[0015] The preparation method of the catalyst includes mixing the modified molecular sieve with alumina or its precursor, extruding into a strip, drying and calcining at 400-580°C.

[0016] In the above catalyst preparation method, the alumina precursor may be one or more of aluminum sol, aluminum gel and pseudo-boehmite, preferably pseudo-boehmite. When extruding, it is preferable to add a peptizer into the mixture of modified molecular sieve and alumina or its precursor. The amount of nitric acid is preferably 20-55% of the mass of the mixture. The drying temperature of the extruded product is preferably 90-120° C., and the drying time is preferably 2-6 hours.

[0017] Among the present invention, the preparation method of described modified molecular sieve comprises:

[0018] (1) Impregnate HZSM-5 molecular sieve or HEU-1 molecular sieve with halogen-containing ammonium salt or acid solution at 50-90°C, dry the impregnated solid, and then roast at 450-550°C to obtain a ha...

example 1

[0040] (1) Preparation of modified HZSM-5 molecular sieve

[0041] Take the HZSM-5 molecular sieve whose silica / alumina molar ratio is 42, and use the concentration of 10% by mass of NH 4 F solution was impregnated at 70°C for 1.5 hours under stirring, the impregnated liquid / solid mass ratio was 5:1, the impregnated solid was dried at 110°C for 4 hours, and roasted at 500°C for 6 hours to obtain fluorine-modified HZSM-5 molecular sieve. The F element content is 2.63% by mass (X-ray fluorescence spectrum (XRF) analysis, the same below).

[0042] Get the fluorine-modified HZSM-5 molecular sieve, use La(NO 3 ) 3 The solution was ion-exchanged at 80°C for 1.5 hours, and the liquid / solid mass ratio of ion exchange was 10:1. The ion-exchanged solid was dried at 110°C for 4 hours and calcined at 520°C for 5 hours to obtain fluorine and La-modified HZSM- 5 Molecular sieve a, wherein the F element content is 2.63% by mass, and the La element content is 1.83% by mass.

[0043] (2) P...

example 2

[0046] (1) Preparation of modified HEU-1 molecular sieve

[0047] Get the HEU-1 molecular sieve that the silica / alumina molar ratio is 40, use the NH that concentration is 10 mass % 4 The F solution was impregnated at 70°C for 1.5 hours under stirring, the impregnated liquid / solid mass ratio was 5:1, the impregnated solid was dried at 110°C for 4 hours, and roasted at 500°C for 6 hours to obtain fluorine-modified HEU-1 molecular sieves. Among them, the F element content is 2.75% by mass.

[0048] Get the fluorine-modified HEU-1 molecular sieve, use Ce(NO 3 ) 3 The solution was ion-exchanged at 80°C for 1 hour, and the liquid / solid mass ratio of ion exchange was 10:1. The ion-exchanged solid was dried at 110°C for 4 hours and calcined at 520°C for 5 hours to obtain fluorine and Ce-modified HEU- 1 Molecular sieve b, wherein the F element content is 2.75% by mass, and the Ce element content is 1.28% by mass.

[0049] (2) Preparation of catalyst

[0050] Mix the modified HEU-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com