Preparation method of furoic acid

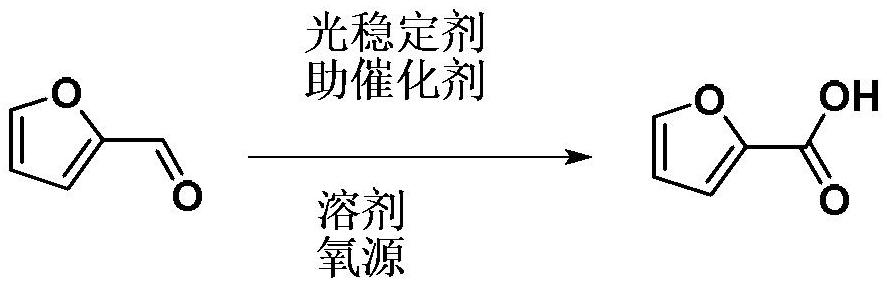

A technology of furoic acid and furfural, which is applied in the field of chemical substance preparation, can solve problems such as poor raw material utilization, many waste products, and large safety hazards, and achieve the effects of increasing selectivity, mild reaction conditions, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

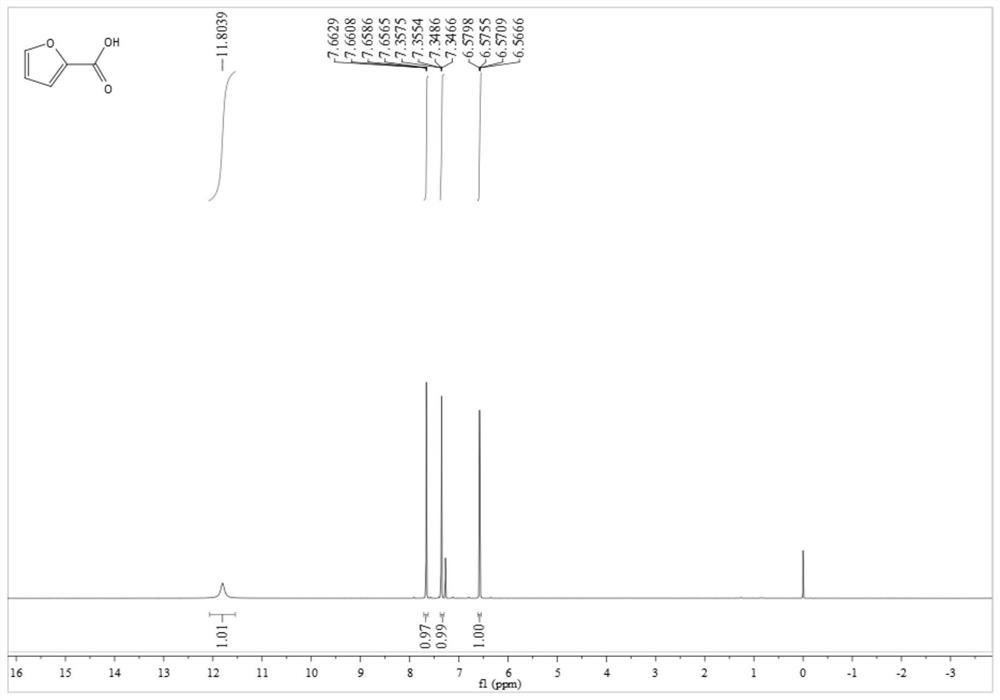

[0023] Take 1mmol of furfural, 10mL of dimethyl sulfoxide, 10mol% Chimassorb 944 and 10mol% sodium tungstate into a 25ml autoclave. After tightening the screws, fill with oxygen. After three replacements, fill the oxygen pressure to 2MPa and raise the temperature under magnetic stirring. React at 80°C for 12 hours. After the reaction is completed, cool to room temperature, add N,N-dimethylformamide as an internal standard, add methanol to dilute, and detect by gas chromatography. The specific detection conditions are as follows: GC (2104, Shimazu, FID) equipped with DB-FFAP (30m x 0.25μm x 0.32mm) chromatographic column for detection of product content. The vaporization temperature was set at 270°C, the detection temperature was set at 270°C, the oven temperature was set at 120°C, kept for 1 minute, then raised to 230°C within 8 minutes, and kept for 8 minutes. The yield of furoic acid was 84%. The NMR spectrum of the prepared furoic acid is as follows figure 1 shown.

Embodiment 2

[0025] The specific reaction process and detection method are the same as in Example 1, except that sodium tungstate is changed to vanadyl sulfate, and the yield of product furoic acid is 72%.

Embodiment 3

[0027] The specific reaction process and detection method are the same as in Example 1, except that sodium tungstate is changed to vanadium pentoxide, and the yield of product furoic acid is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com