Cerium oxide modified microwave hydrothermal carbon as well as preparation method and application thereof

A microwave hydrothermal and cerium oxide technology is applied in the preparation/processing of cerium oxide/cerium hydroxide, rare earth metal compounds, and the preparation/purification of carbon, which can solve unstable processing effects, restrict application, investment, and operating costs. High problems, to achieve the effect of low-cost in-situ desulfurization, quality improvement, and corrosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

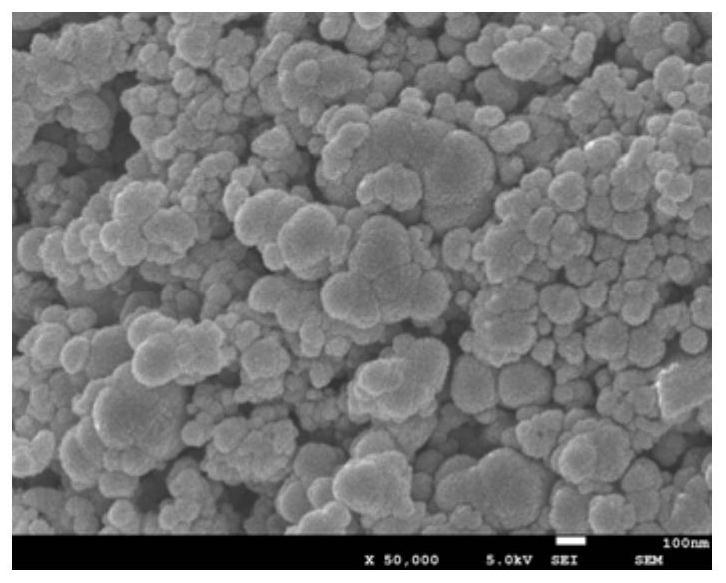

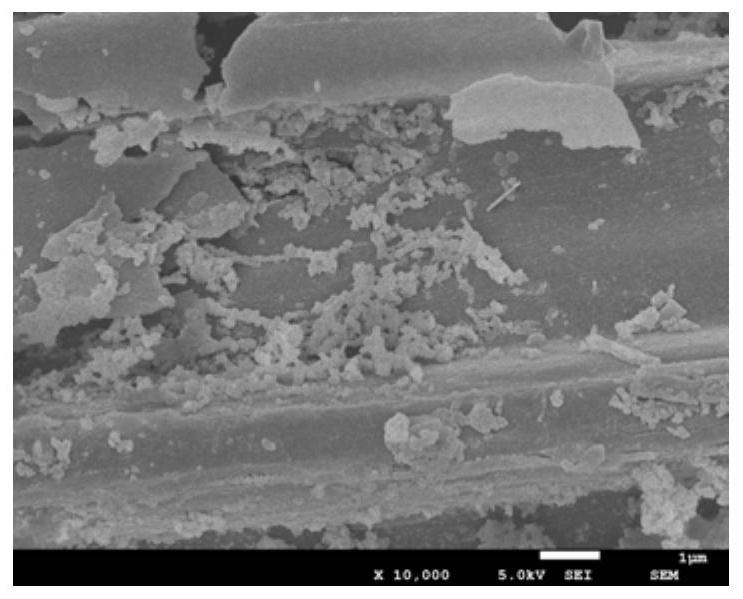

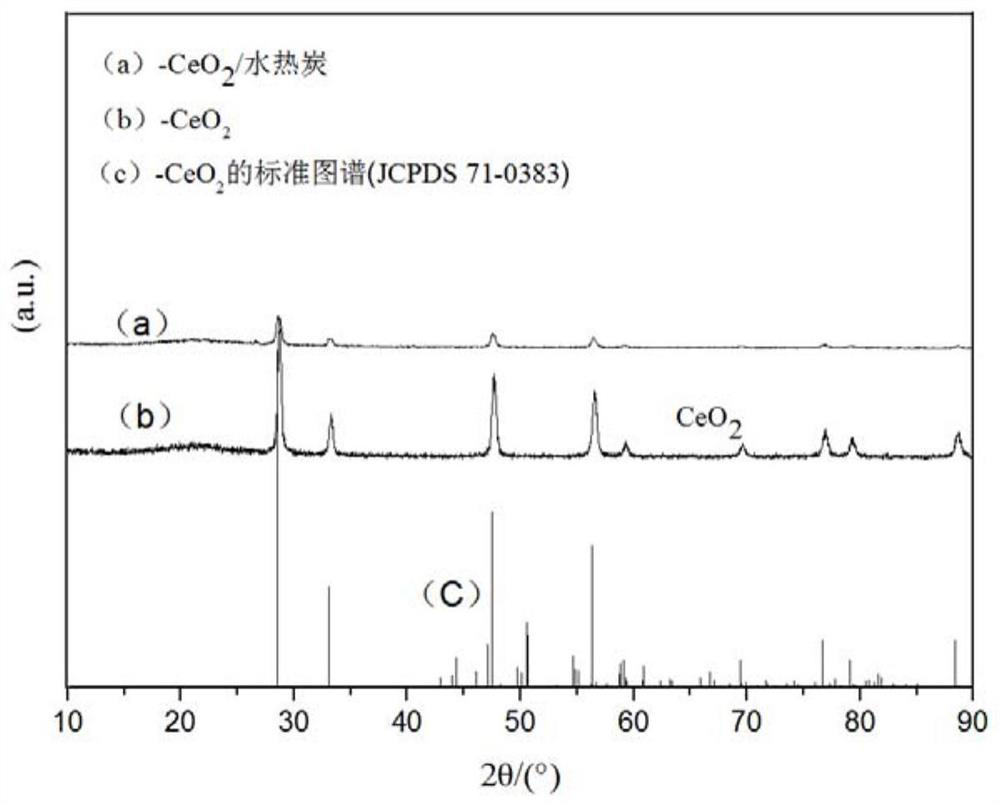

[0022] The preparation method of cerium oxide modified microwave hydrothermal carbon is prepared according to the following steps: (1) the human feces in the septic tank are naturally air-dried outdoors until the water content is 35%-45%, impurities are removed, freeze-dried, and sieved After 200 mesh sieve, keep away from light for later use.

[0023] (2) Preparation of Ce(NO 3 ) 3 ·6H 2 O solution, and add ammonia to it. Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.15 mol / L, and the concentration of ammonia water is 7 mol / L.

[0024] (3) Add directing agent SDS to the above solution, directing agent and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O was 2:1, and then added to dry feces, and the mass of cerium oxide was controlled to be 20%, 30% and 40% of the mass of dry human feces, respectively. Microwave heating reaction, the microwave power is 400W, the pressure control is 1.8Mpa, and the heating time is 2h.

[0025] The prepared cerium oxide modified microwave hydro...

Embodiment 2

[0032] The preparation method of cerium oxide modified microwave hydrothermal carbon is prepared according to the following steps: (1) the human feces in the septic tank are naturally air-dried outdoors until the water content is 35%-45%, impurities are removed, freeze-dried, and sieved After 200 mesh sieve, keep away from light for later use.

[0033] (2) Preparation of Ce(NO 3 ) 3 ·6H 2 O solution, and add ammonia to it. Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.15 mol / L, and the concentration of ammonia water is 7 mol / L.

[0034] (3) Add directing agent SDS to the above solution, directing agent and Ce(NO 3 ) 3 ·The molar ratio of 6H2O is 2:1, then add the dried feces, and respectively control the quality of cerium oxide to be 30% of the dry human feces. Microwave heating reaction, the microwave power is 400W, the pressure is controlled at 1.5Mpa, 1.8Mpa and 2.0Mpa respectively, and the heating time is 2h.

[0035] The prepared ceria-modified microwave hydroth...

Embodiment 3

[0040] The preparation method of cerium oxide modified microwave hydrothermal carbon is prepared according to the following steps: (1) the human feces in the septic tank are naturally air-dried outdoors until the water content is 35%-45%, impurities are removed, freeze-dried, and sieved After 200 mesh sieve, keep away from light for later use.

[0041] (2) Preparation of Ce(NO 3 ) 3 ·6H 2 O solution, and add ammonia to it. Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.15 mol / L, and the concentration of ammonia water is 7 mol / L.

[0042] (3) Add directing agent SDS to the above solution, directing agent and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O was 2:1, and then added to the dry feces, and the quality of cerium oxide was controlled to be 30% of the dry human feces. Microwave heating reaction, the microwave power is 400W, the pressure control is 1.8Mpa, and the heating time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com