Method for preparing vanitrope from sassafras oil

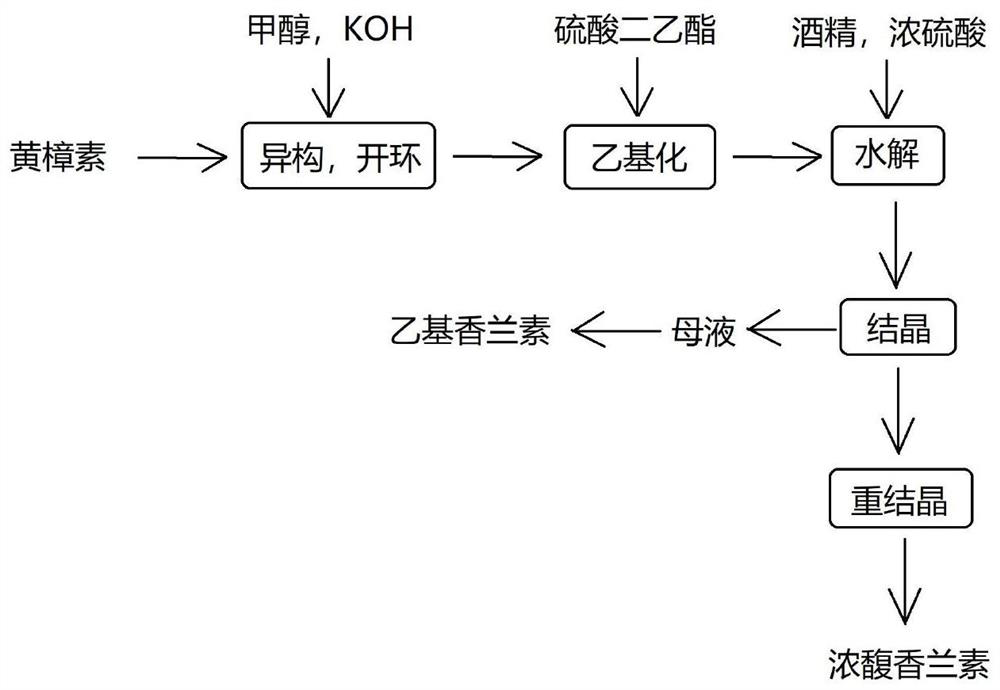

A technology for concentrating vanillin and sassafras oil, applied in ether preparation, ether separation/purification, organic chemistry and other directions, can solve the problems of high temperature, low reaction yield, low yield and the like, and achieves reduction of processing process and cost , the reaction is mild and controllable, and the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing strong vanillin from sassafras oil, comprising the following steps:

[0026] S1. Add 100g of sassafras oil, 100g of methanol and 100g of potassium hydroxide to the reaction kettle simultaneously, stir and control the reaction temperature at 130°C, reflux for 60min, then carry out atmospheric distillation and raise the temperature to 150-160°C to Methanol was distilled off, and the reaction was continued for 4-8h;

[0027] S2. Sampling the mixed solution in the reaction kettle. When the content of safrole in it is less than 1%, it is judged that the reaction is over. After the reaction is over, stop the reaction, and cool down to below 100 ° C. Add appropriate amount of water under stirring, and then let it stand for separation Layer, collect the methoxyisoeugenol potassium salt solution of the upper layer;

[0028] S3. Add 320 g of methoxyisoeugenol potassium salt solution collected in step S2 and 108 g of diethyl sulfate into another reaction ke...

Embodiment 2

[0034] A method for preparing strong vanillin from sassafras oil, comprising the following steps:

[0035] S1. Add 150g of sassafras oil, 150g of methanol and 400g of potassium hydroxide to the reaction kettle at the same time, stir and control the reaction temperature at 125°C, reflux for 120min, then carry out atmospheric distillation and raise the temperature to 130-140°C to Methanol was distilled off, and the reaction was continued for 4-8h;

[0036] S2. Sampling the mixed solution in the reaction kettle. When the content of safrole in it is less than 1%, it is judged that the reaction is over. After the reaction is over, stop the reaction, and cool down to below 90°C. Layer, collect the methoxyisoeugenol potassium salt solution of the upper layer;

[0037] S3. Add 320 g of the methoxyisoeugenol potassium salt solution collected in step S2 and 320 g of diethyl sulfate into another reaction kettle, stir and raise the temperature to 100°C, and keep the temperature for 2-3 h...

Embodiment 3

[0043] A method for preparing strong vanillin from sassafras oil, comprising the following steps:

[0044] S1. Add 100g of sassafras oil, 200g of methanol and 600g of potassium hydroxide to the reaction kettle at the same time, stir and control the reaction temperature at 110°C, reflux for 100min, then carry out atmospheric distillation and raise the temperature to 160-180°C to Methanol was distilled off, and the reaction was continued for 4-8h;

[0045] S2. Sampling the mixed solution in the reaction kettle. When the content of safrole in it is less than 1%, it is judged that the reaction is over. After the reaction is over, stop the reaction, and cool down to below 90°C. Layer, collect the methoxyisoeugenol potassium salt solution of the upper layer;

[0046] S3. Add 320 g of methoxyisoeugenol potassium salt solution collected in step S2 and 80 g of diethyl sulfate into another reaction kettle, stir and raise the temperature to 90° C., keep warm for 2-3 hours, after the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com