Polycarboxylate gypsum water reducing agent and preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylate gypsum water reducing agent and its preparation, which can solve the problems of poor strength of hardened body, large water consumption for standard thickening, and long setting time, etc., so as to reduce the setting time , reduce economic costs, and produce simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

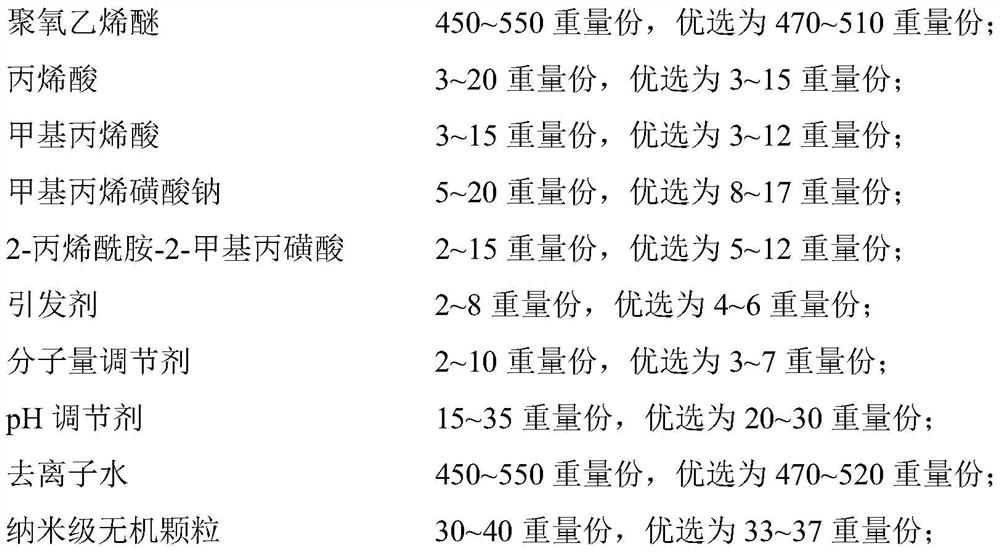

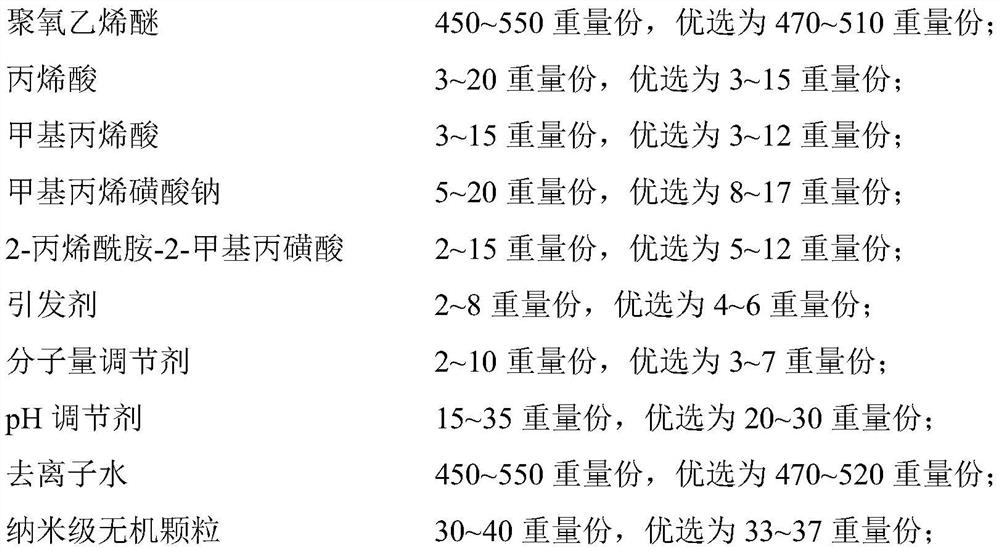

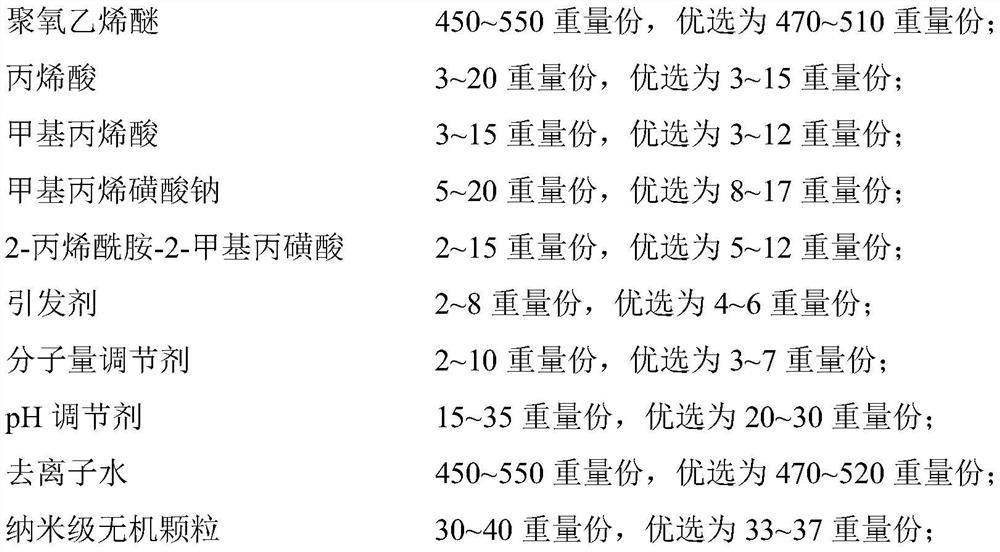

Method used

Image

Examples

Embodiment 1

[0059] S1. Add 500 g of early-strength monomer ES9201, 400 g of deionized water, 2 g of hydrogen peroxide, and 11.85 g of sodium methacrylate into a four-neck flask with a capacity of 1 L connected to a stirring device and a thermometer. Ammonium persulfate 2g, configured as a bottom solution;

[0060] S2. Add 9 g of acrylic acid, 6 g of methacrylic acid, 10.35 g of 2-acrylamide-2-methylpropanesulfonic acid, and 32 g of deionized water into conical flask A to obtain liquid A; wherein, the acrylic acid and methacrylic acid Mass ratio 3:2;

[0061] S3. Add 1 g of ascorbic acid and 75 g of deionized water to Erlenmeyer flask B to obtain liquid B;

[0062] S4. Use a peristaltic pump to continuously drop liquid A and liquid B into the bottom liquid of the four-necked flask, and control the dropping time for 180 minutes under constant stirring, and the reaction temperature is 45°C; after the dropping is completed, keep warm for 1 hour and react , add 7.45g sodium hydroxide and 22....

Embodiment 2

[0065] Example 2 is basically the same as Example 1, except that in step S2, 12 g of acrylic acid and 6 g of methacrylic acid are added to the Erlenmeyer flask A, and the mass ratio of acrylic acid to methacrylic acid is 2:1.

[0066] Finally, polycarboxylate gypsum water reducer is obtained. The performance test was carried out on the samples of polycarboxylate gypsum water reducer, and the test results are shown in Table 1.

Embodiment 3

[0068] Example 3 is basically the same as Example 1, except that in step S2, 15 g of acrylic acid and 6 g of methacrylic acid are added to the Erlenmeyer flask A, and the mass ratio of acrylic acid to methacrylic acid is 5:2.

[0069] Finally, polycarboxylate gypsum water reducer is obtained. The performance test was carried out on the samples of polycarboxylate gypsum water reducer, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com