Fin type photovoltaic silicon-based plasmon hot carrier infrared detection chip and manufacturing method thereof

A technology of plasmons and hot carriers, applied in the field of photoelectric detection, can solve the problems of high dark current, inability to work with silicon materials, low quantum efficiency and low detection rate, and achieve the effect of strong radiation resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

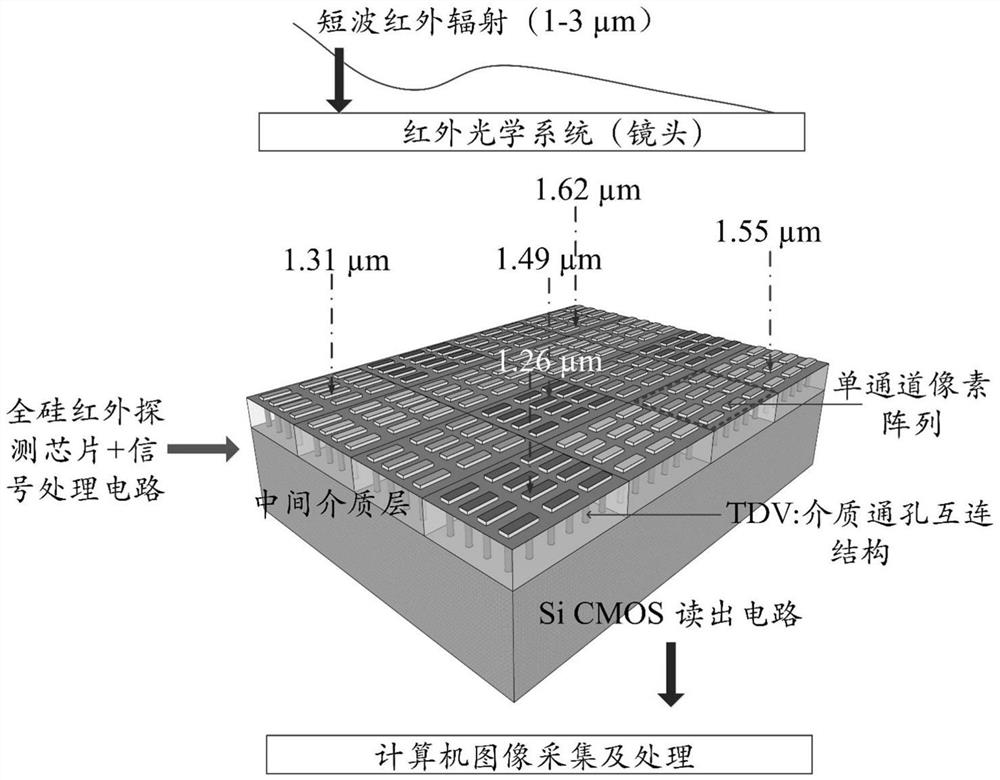

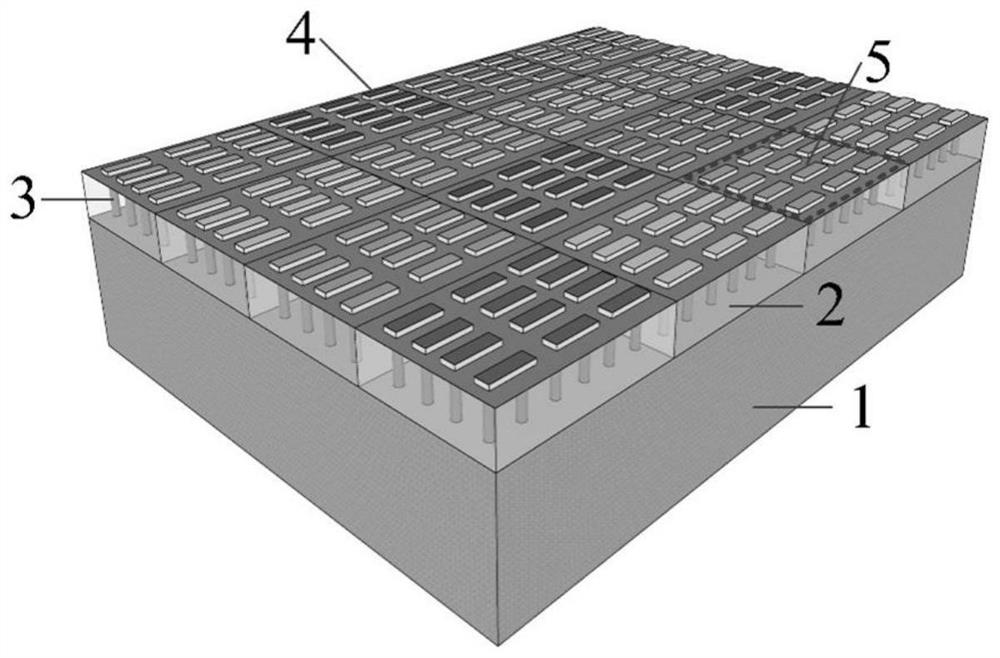

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. refer to Figure 1-3 As shown, the entire device structure includes:

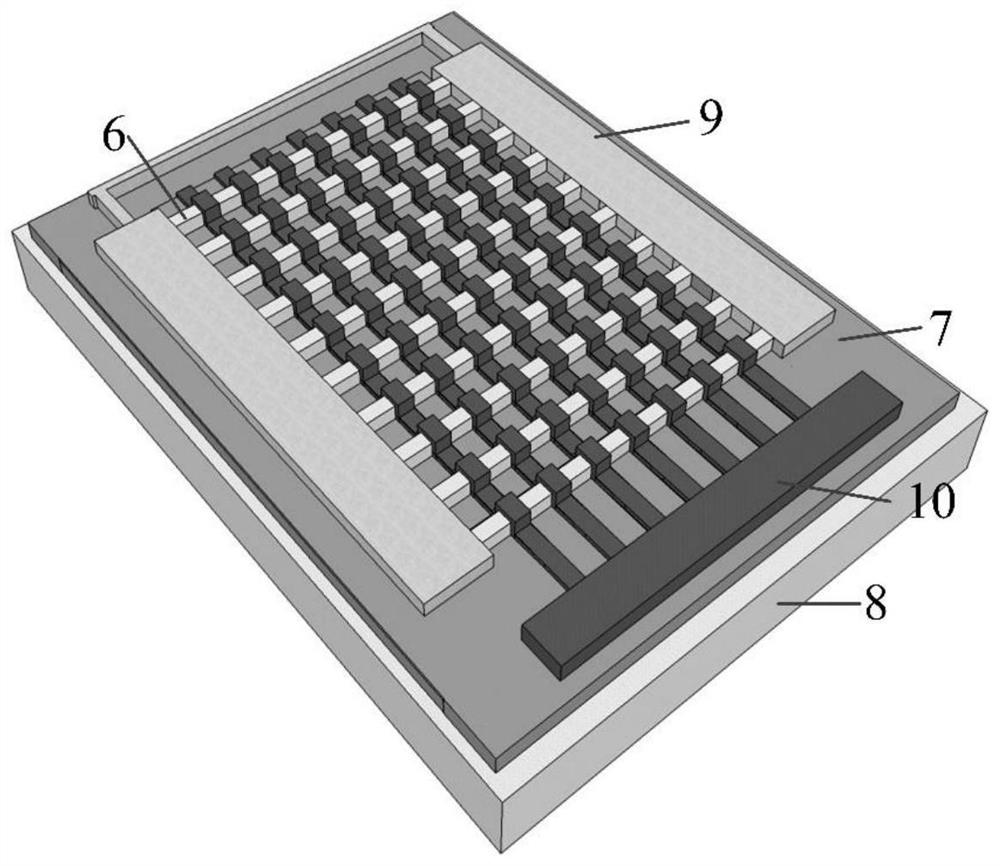

[0065] A silicon-on-insulator (SOI) substrate. The bottom layer of the substrate is a common silicon material used to prepare CMOS signal readout circuits; the middle layer is a dielectric layer, which can integrate through-hole interconnection structures inside; the top layer is a thin A layer of silicon, as an infrared light-sensitive layer, distributes several sub-arrays responding to different single-bands inside it, and single-pixel fin photovoltaic devices distributed in each sub-array. Among them, the single-pixel fin-type photovoltaic device structure, such as image 3 Shown: It consists of a silicon nanowire array with a specific period on the SOI substrate, aluminum electrodes connected at both ends, and a fin-like structure metasurface with a common connection terminal int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com