Angelica keiskei powder processing method

A processing method and pulverizer technology, which are applied in the direction of food ingredients as taste improvers, functions of food ingredients, food ingredients containing natural extracts, etc., can solve the problems of less research on processing technology, loss of nutritional ingredients, etc., and achieve the content of active ingredients Improve the effect of high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for processing Ashitaba powder, specifically comprising the steps of:

[0057] Step 1: Wash and cut into sections. Choose fresh ashitaba, remove rotten and diseased ashitaba, immerse in a solution with a chloride ion content of 200mg / kg for 3 minutes, wash the surface sediment with tap water, rinse and cut into 2-3cm pieces.

[0058] Step 2: Color protection. Immediately put Ashitaba into CaCl-containing 2 0.8% color protection treatment in the color protection solution.

[0059] Step 3: Precook. Ashitaba sections are precooked at 90°C for 3 minutes.

[0060] Step 4: Beating. Beat the color-protected Ashitaba section, heat distilled water equivalent to 1 times the volume of the pre-cooked Ashitaba mass (solid-to-liquid ratio 100g / 100mL) to boiling, pour it into the Ashitaba section and heat for 3 minutes, and then crush it with tissue Machine beating.

[0061]Step Five: Micro-crushing. Use a colloid mill combined with a high-shear homogenizer for wet mi...

experiment example 1

[0065] Experimental Example 1 Comparative Analysis of Vc and Chalcone Contents of Ashitaba Dried Processed Products and Processed Products of the Present Invention

[0066] 1. Establishment of detection method

[0067] 1.1 Determination method of ascorbic acid Vc content

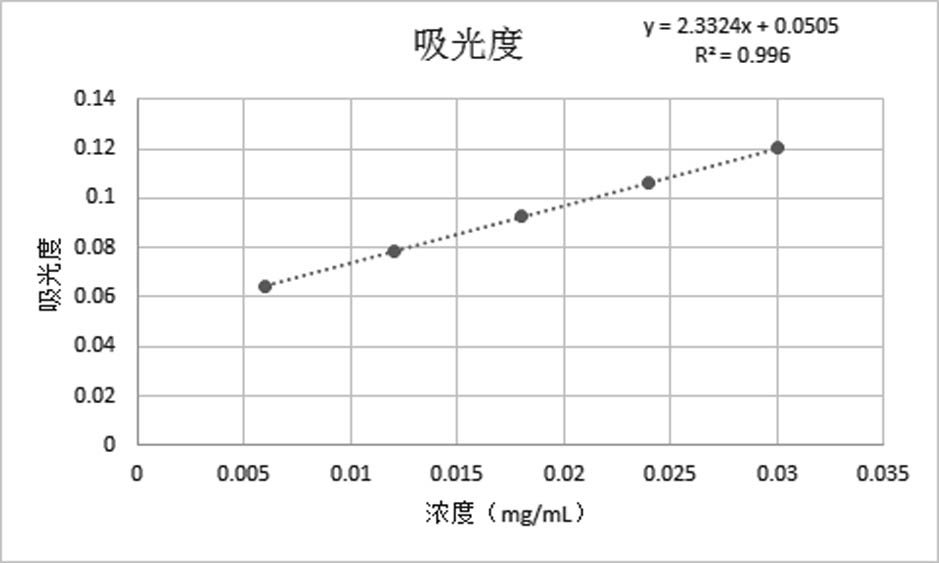

[0068] Refer to GB 12392-90 4-dinitrophenylhydrazine method. Total ascorbic acid Vc includes reduced form, dehydrogenated form and diketogulonic acid. The reduced form of ascorbic acid in the sample is oxidized by activated carbon to dehydroascorbic acid, and then reacts with 2,4-dinitrophenylhydrazine to form red oleo, which is colored The intensity is proportional to the total ascorbic acid content, and can be quantified by colorimetry. The regression equation made according to the determination method is: y=2.3324x+0.0505, R 2 =0.996 standard curve see figure 1 .

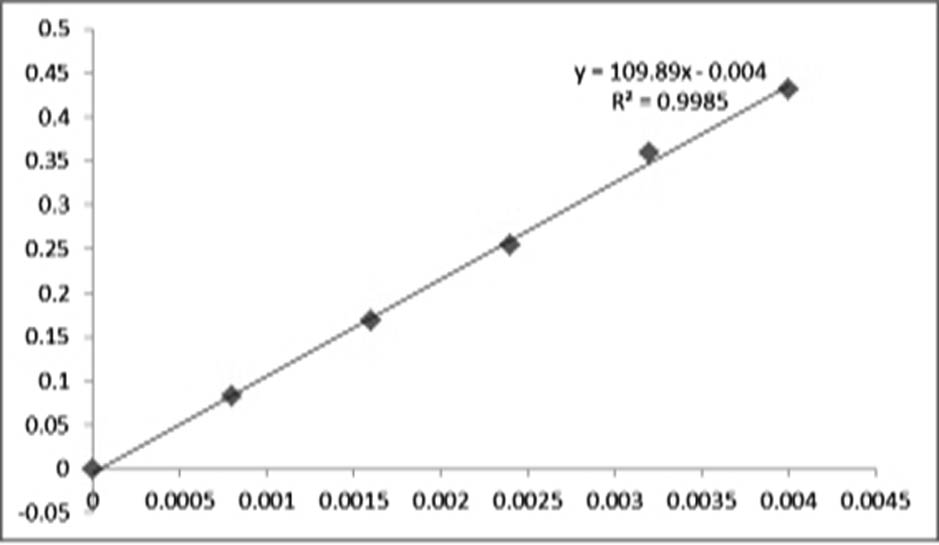

[0069] 1.2 Method for Determination of Chalcones in Ashitaba

[0070] Chalcone standard curve preparation: Use a precision electronic bal...

experiment example 2

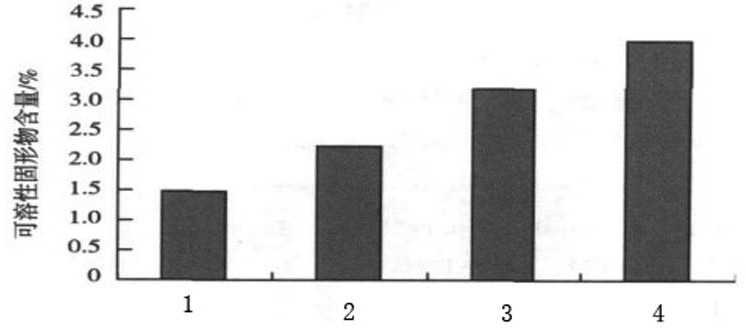

[0075] Experimental example 2 The influence of conditional parameters on solubility

[0076] Direct beating: Weigh 150g of Ashitaba and add 250mL of pure water, beat for 10min with a tissue pulverizer, then pulverize with a colloid mill, filter and measure the refractive index with an Abbe refractometer.

[0077] Precooking and beating: Weigh 150g of ashitaba and add 250mL of pure water, and precook in an induction cooker above 90°C for 3 minutes; then beat it with a tissue grinder for 10 minutes, then finely pulverize it with a colloid mill, filter and measure the refractive index with an Abbe refractometer.

[0078] High-shear homogenization: Weigh 150g ashitaba and add 250mL of pure water, precook in an induction cooker above 90°C for 3 minutes; then use a tissue pulverizer to grind for 10 minutes, then finely pulverize with a colloid mill, and then perform high-shear homogenization. After filtration, the refractive index was measured with an Abbe refractometer.

[0079] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com