High-dispersion ruthenium-loaded surface-modified layered titanate nanosheet photocatalyst as well as preparation method and application thereof

A layered titanate and surface modification technology, which is applied in the field of ammonia synthesis, can solve the problems that the nitrogen fixation reaction cannot proceed spontaneously and the kinetics are limited, and achieve mild and not harsh reaction conditions, low equipment requirements, and less time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

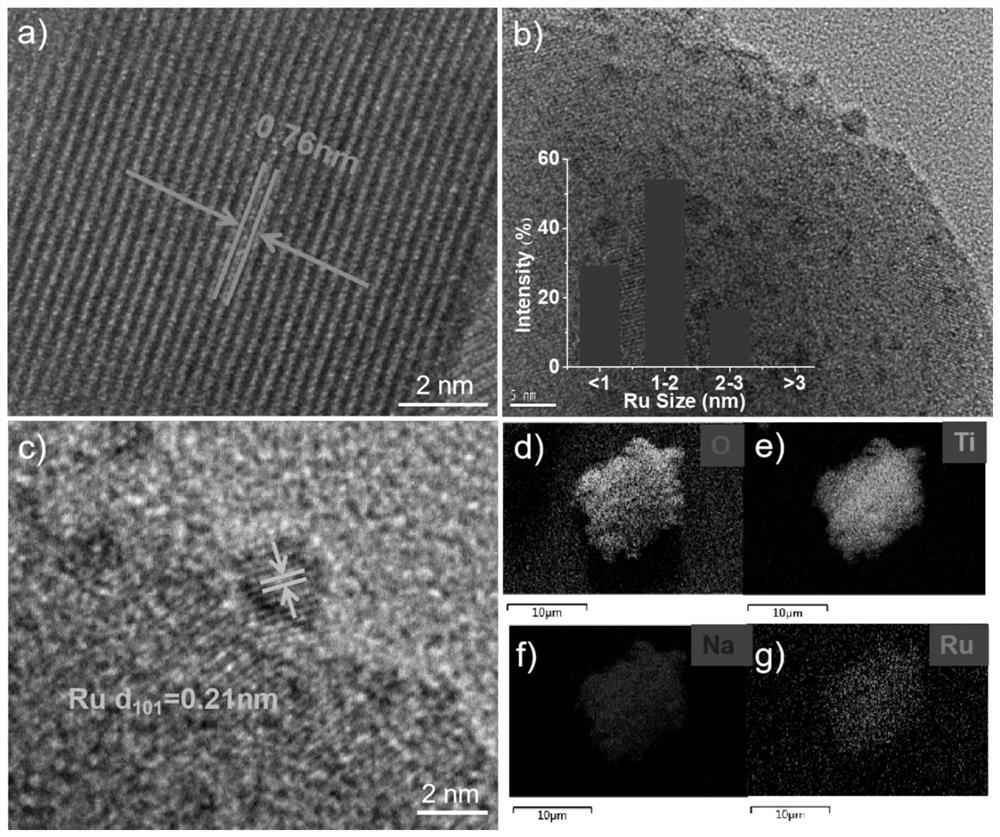

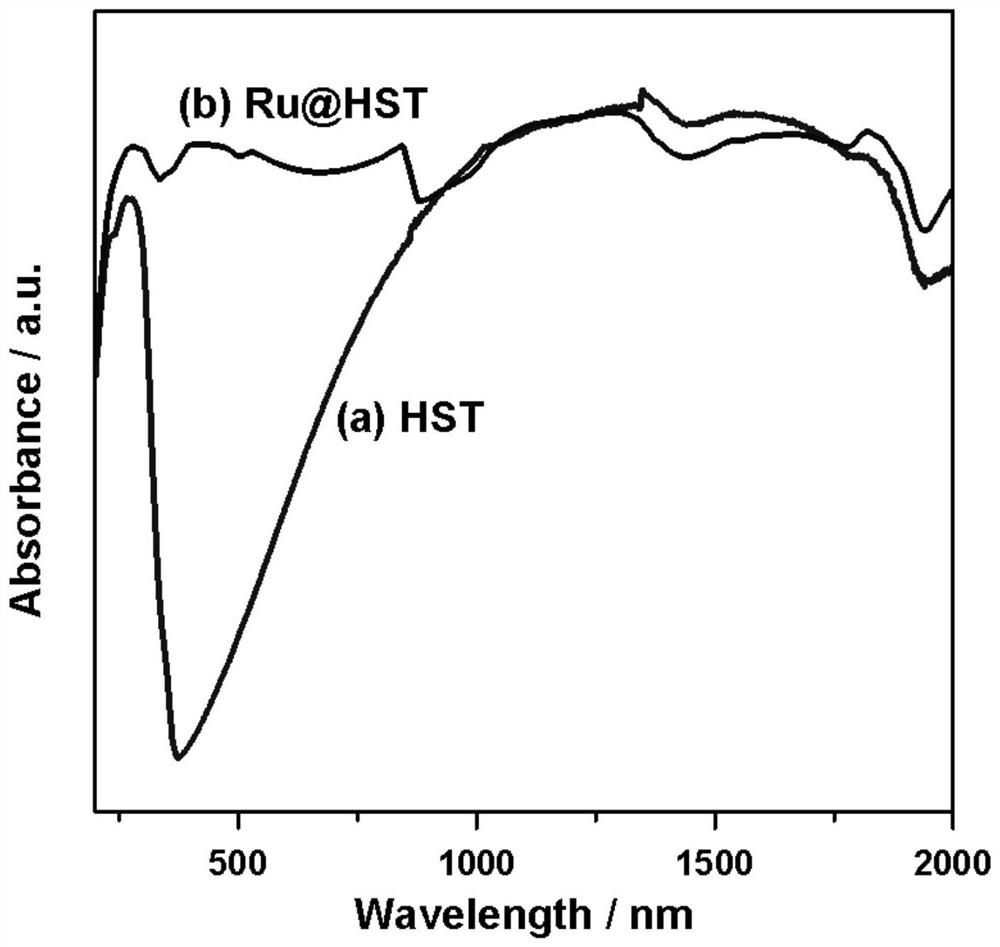

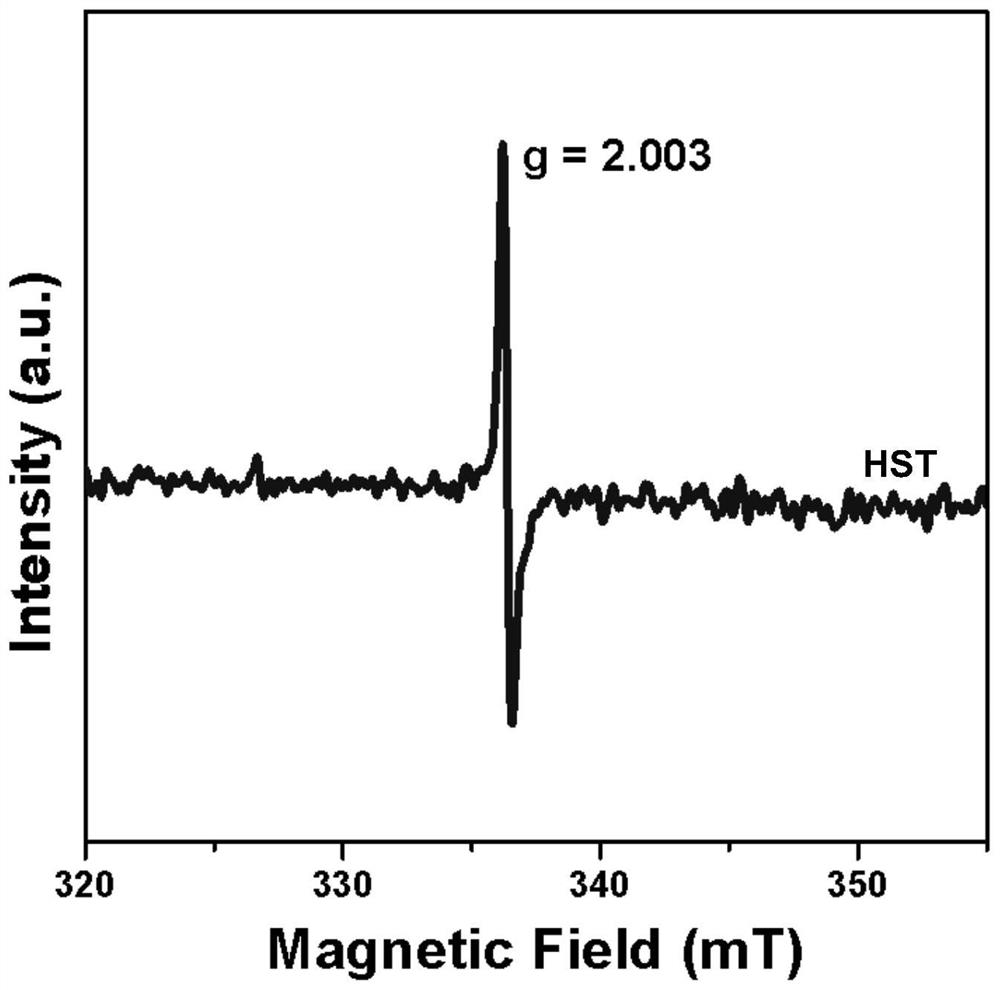

[0027] (1) Preparation of layered titanate nanosheets modified with deficient oxygen: Titanium foil and 50 mL of 5 M NaOH solution were placed in a high-pressure reactor, and then placed in an electric constant temperature blast drying oven at 180° C. for 10 h. After the reaction was completed and cooled to room temperature, the obtained sample was washed several times with ethanol, and the washed sample was calcined at 650° C. for 4 hours in an atmosphere of argon-hydrogen mixture (5% volume hydrogen) to obtain a layered oxygen-deficient modified layer. The transmission electron microscope image of titanate nanosheet HST is shown in Figure (1a). The mass of the prepared catalyst was 2 mg, and the proportion of deficient oxygen in all oxygen elements was 42.9%.

[0028] (2) Preparation of 0% highly dispersed ruthenium-loaded surface-modified layered titanate nanosheets Ru@HST: the HST obtained in step (1) was transferred to the bottom of the quartz reactor, and calcined at 150...

Embodiment 2

[0031] (1) Preparation of layered titanate nanosheets modified by deficient oxygen: same as in Example 1, the ratio of deficient oxygen to all oxygen elements is 42.9%.

[0032] (2) Preparation of 1% highly dispersed ruthenium-loaded surface-modified layered titanate nanosheets Ru@HST: Weigh 0.02 mg of triruthenium dodecacarbonyl and dissolve it in 1.5 mL of anhydrous tetrahydrofuran, and then mix the prepared solution with 2 mg of the catalyst was mixed, the sample was transferred to the bottom of the quartz reactor, the tetrahydrofuran was drained by a diaphragm pump, and the mixture was calcined at 150°C for 1 h under vacuum to obtain a layered titanate nanosheet photocatalyst with a highly dispersed ruthenium-loaded surface modification, the product The mass is 2.00 mg. The mass of metal ruthenium in the photocatalyst accounts for 1% of the mass of the whole catalyst (2 mg).

[0033] (3) The operation of the photocatalytic nitrogen fixation reaction: the quartz reactor eq...

Embodiment 3

[0035] (1) Preparation of layered titanate nanosheets modified by deficient oxygen: same as in Example 1, the ratio of deficient oxygen to all oxygen elements is 42.9%.

[0036] (2) Preparation of 5% highly dispersed ruthenium-loaded surface-modified layered titanate nanosheet Ru@HST: Weigh 0.1 mg triruthenium dodecacarbonyl and dissolve it in 1.5 mL anhydrous tetrahydrofuran, and then mix the prepared solution with 2 mg of the catalyst was mixed, the sample was transferred to the bottom of the quartz reactor, the tetrahydrofuran was drained by a diaphragm pump, and the mixture was calcined at 150°C for 1 h under vacuum to obtain a layered titanate nanosheet photocatalyst with a highly dispersed ruthenium-loaded surface modification, the product The mass is 2.00 mg. The mass of metal ruthenium in the photocatalyst accounts for 5% of the mass of the whole catalyst (2 mg).

[0037] (3) The operation of the photocatalytic nitrogen fixation reaction: the quartz reactor equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com