TPU sheath material for charging cables as well as preparation and application of TPU sheath material

A charging cable and sheath material technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of easy cracking of TPU sheath material, poor matte effect, easy to be bitten by mice, etc. Achieve the effect of improving anti-cracking performance, excellent effect, and preventing rat bites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

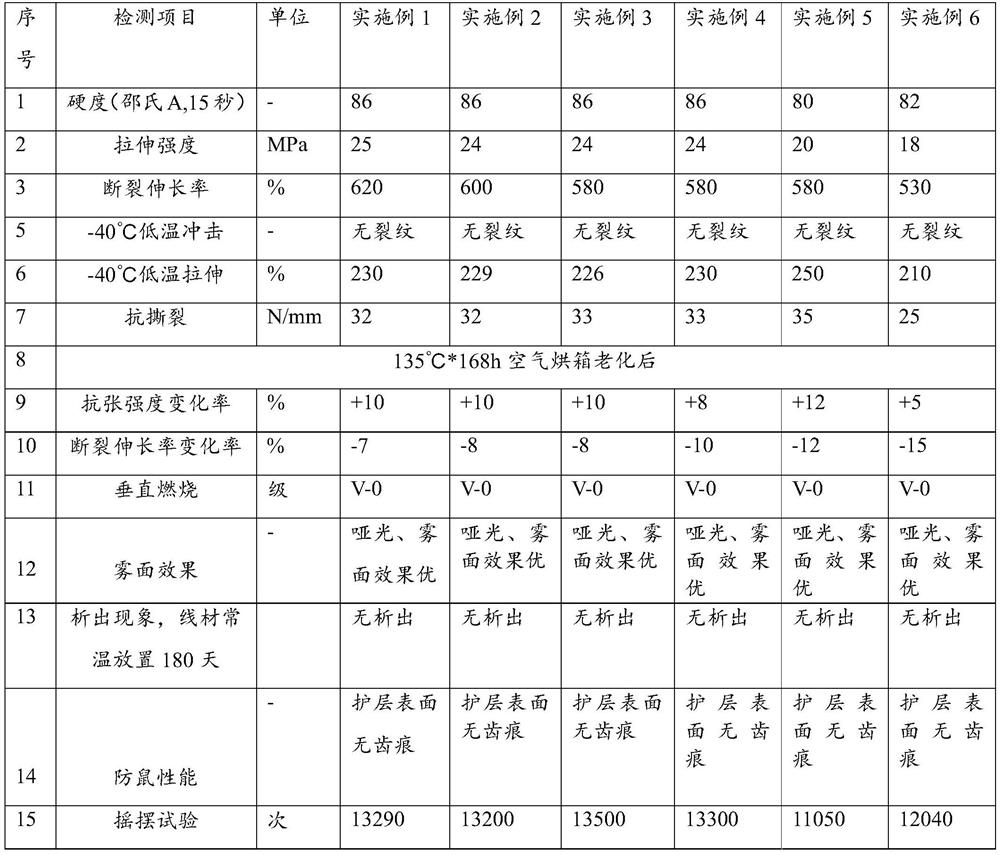

Examples

preparation example Construction

[0062] In a second aspect, a method for preparing a TPU sheathing material for a charging cable in the first aspect is provided, comprising the steps of:

[0063] S1. Mix the raw materials except thermoplastic polyurethane TPU evenly to obtain the mixture;

[0064] S2. Drying the thermoplastic polyurethane TPU;

[0065] S3. Mix the above mixture and the dried thermoplastic polyurethane TPU evenly, extrude and granulate through a twin-screw extruder to prepare the flame-retardant and anti-cracking TPU sheath material for the charging cable.

[0066] Wherein, the drying treatment temperature in step S2 is 70-100°C, and the drying treatment time is 4-8h; the extrusion temperature of the twin-screw extruder in step S3 is 160-200°C, such as 160°C, 165°C, 170°C °C, 175°C, 180°C, 185°C, 190°C, 200°C and any value between them.

[0067] In the third aspect, an application of the TPU sheathing material for charging cables described in the first aspect to electric vehicle charging cab...

Embodiment 1

[0070] A TPU sheathing material for a charging cable, prepared from the following raw materials in parts by weight: 50 parts of thermoplastic polyurethane TPU; 7 parts of modifier; 3 parts of compatibilizer; 35 parts of halogen-free flame retardant; 8 parts of flame retardant synergist 1 part; lubricant 1 part; antioxidant 1 part; rodent-proof agent 1.5 parts.

[0071]Wherein, the thermoplastic polyurethane TPU is polyether type TPU; the modifier is ethylene-methyl acrylate copolymer (EMMA); the compatibilizer is ethylene-vinyl acetate copolymer grafted maleic anhydride copolymer ( EVA-MAH); The halogen-free flame retardant is composed of nitrogen-based halogen-free flame retardant and phosphorus-based halogen-free flame retardant; the flame-retardant synergist is nano-montmorillonite; the nitrogen-based halogen-free flame retardant The flame retardant is melamine polyphosphate; the phosphorus-based halogen-free flame retardant is aluminum diethylphosphinate; the lubricant is ...

Embodiment 2

[0078] A TPU sheathing material for a charging cable, prepared from the following raw materials in parts by weight: 20 parts of thermoplastic polyurethane TPU; 5 parts of modifier; 10 parts of compatibilizer; 10 parts of halogen-free flame retardant; 5 parts of flame retardant synergist parts; 0.5 parts of lubricant; 0.5 parts of antioxidant; 0.5 parts of anti-rodent agent.

[0079] Wherein, the thermoplastic polyurethane TPU is polyester poly TPU; the modifying agent is ethylene-vinyl acetate copolymer (EVA); the compatibilizer is ethylene-octene copolymer grafted maleic anhydride copolymer ( POE-MAH) and ethylene-vinyl acetate copolymer grafted maleic anhydride copolymer (EVA-MAH); the halogen-free flame retardant is composed of a nitrogen-based halogen-free flame retardant and a phosphorus-based halogen-free flame retardant; the The flame retardant synergist is kaolin; the nitrogen-based halogen-free flame retardant is melamine cyanurate; the phosphorus-based halogen-free f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com