Manufacturing method of low-cost terahertz photoconductive antenna with nano electrode

A photoconductive antenna and nano-electrode technology, which is applied in the field of terahertz photoconductive antenna production, can solve the problems of difficult metal stripping, slow speed, and high exposure cost, and achieve the effect of improving processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

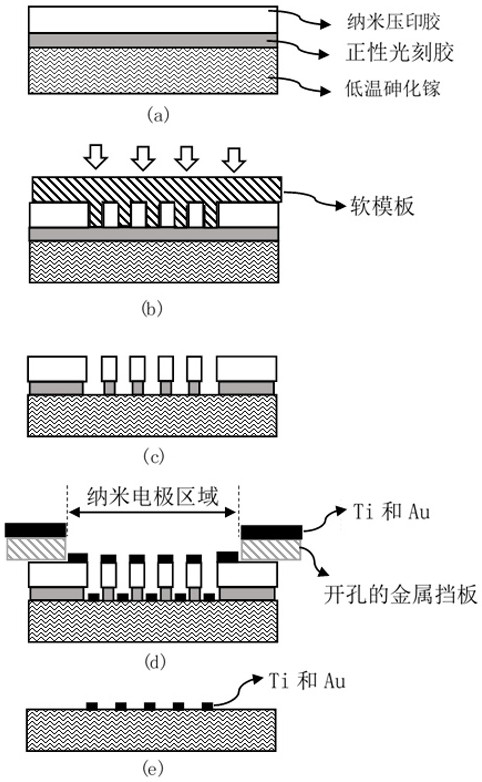

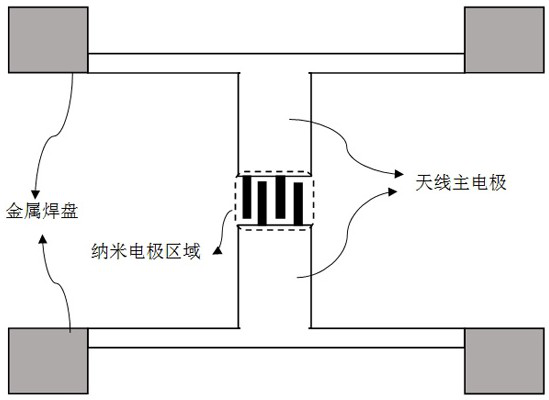

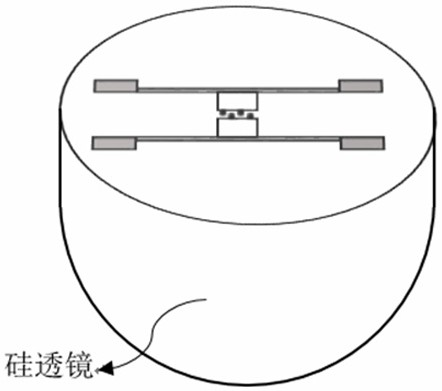

[0027] After cleaning the gallium arsenide wafer prepared by low-temperature growth, spin-coat a layer of S1805 positive photoresist solution with a concentration of 20wt%, with a thickness of 60nm, bake it on a hot plate at 95°C for 60s, and then spin-coat a layer of nano-pressurized Printing glue, the thickness is 200nm. Use a conventional hard template to pre-print a DMS soft template with a sub-micron precision nano-electrode pattern structure, and then use the DMS soft template to perform heat-assisted UV imprinting to transfer the sub-micron precision nano-electrode pattern to the adhesive film, and then Remove soft templates. Use oxygen plasma etching technology to remove the nano-imprint glue and S1805 positive photoresist in the imprint trench, exposing the gallium arsenide wafer. Rinse with 1wt% KOH solution for 9 seconds, dissolve part of the photoresist laterally, and obtain an inverted double-layer adhesive film in the nano-electrode area, and then bake it on a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com