A preparation method of 600mpa ultra-high-strength anti-seismic steel bar

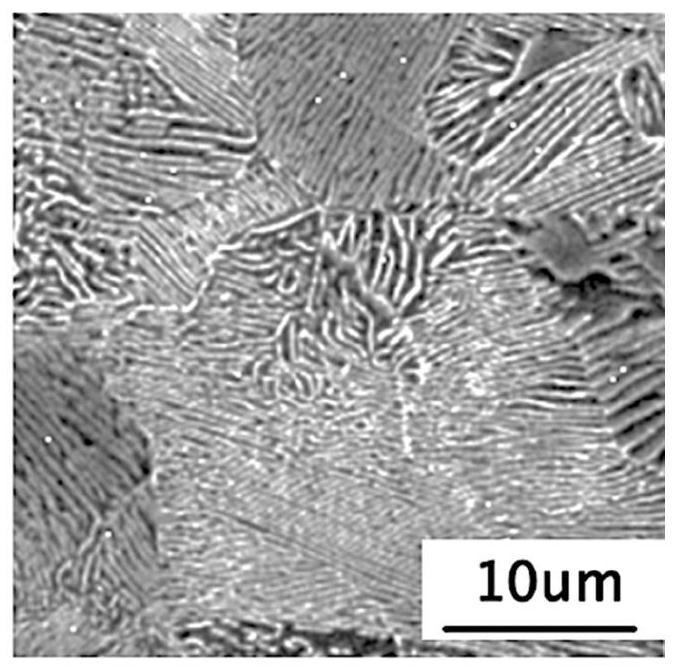

An anti-seismic reinforcement and ultra-high-strength technology, which is applied in the manufacturing process of reinforcement, can solve problems such as unevenness, excessive pearlite structure, and insufficient reinforcement strength, and achieve the effects of uniform distribution, excellent mechanical properties, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

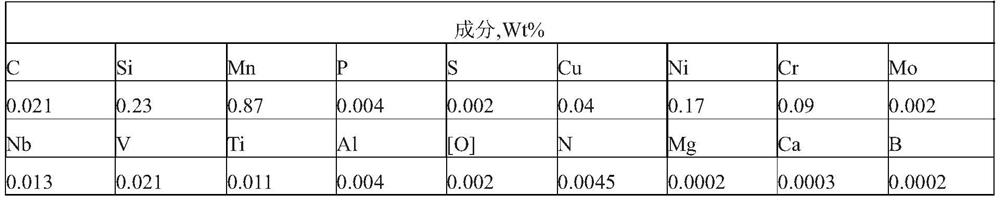

[0032] Billet smelting is carried out in the production mode of large tonnage (100T) converter-LF furnace refining-RH furnace vacuum treatment-250mm section casting machine. Converter smelting molten iron requires P≤0.110%, S≤0.010%, molten iron temperature ≥1300°C, after smelting, the steel is deoxidized by elements forming weak oxides during the tapping process, and the feeding sequence of tapping is: active lime-manganese alloy-silicon system alloy. The amount of active lime added is 350-450kg, and 30kg of calcium carbide is added when tapping. Keep the argon fully open from the beginning of tapping to 3 / 4 of tapping, and then switch to a small flow rate. After tapping, the small flow rate is turned on at 200L / min×3-5 minutes. The temperature after the furnace is ≥1540°C. During the treatment process of LF furnace, it is required to keep the white slag for ≥15 minutes, and adjust the composition to the target composition. When heating, maintain the submerged arc operatio...

Embodiment 1

[0042] 1) Adding carbide alloying elements: feeding V alloy wire, the feeding amount is 490 meters, and the total amount of the alloying elements after the control is increased to 450PPm. Then immediately blow argon gas weakly through the bottom of the tank and stir. The flow rate of argon gas is controlled according to the diameter (average diameter length) of the exposed surface of the molten steel at the gas outlet point of 78 mm. The stirring time is 8 minutes, and the temperature is controlled at 1100 ° C.

[0043] 2) After the addition of carbide alloy elements is completed, cast on the continuous casting machine within 9 minutes, control the superheat of the tundish at 15-25°C, and control the size of the cast slab. The cast slab obtained is soaked in a temperature range of 1150° C., and then sprayed with high-pressure water to remove the iron oxide scale on the surface of the slab.

[0044] 3) Cast billets are rolled: the rolling temperature range is 1000°C, and the ti...

Embodiment 2

[0047] 1) Adding carbide alloying elements: feeding Nb alloy wire, the feeding amount is 350 meters, and the total amount of the alloying elements after the control is increased to 340PPm. Then immediately blow argon gas weakly through the bottom of the tank and stir. The flow rate of argon gas is controlled according to the diameter (average diameter length) of the exposed surface of the molten steel at the gas outlet point of 69 mm. The stirring time is 8 minutes, and the temperature is controlled at 1050 ° C.

[0048] 2) After the addition of carbide alloy elements is completed, cast on the continuous casting machine within 9 minutes, control the superheat of the tundish at 15-25°C, and control the size of the cast slab. The cast slab obtained is soaked in a temperature range of 1150° C., and then sprayed with high-pressure water to remove the iron oxide scale on the surface of the slab.

[0049] 3) Cast billets are rolled: the rolling temperature range is 1100°C, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com