Efficient and stable inorganic lead-free perovskite solar cell and preparation method thereof

A solar cell, lead-free perovskite technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve problems such as low photoelectric conversion efficiency of solar cells, improve film and crystal defects, improve surface electron cloud density, and increase vacancies energy-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

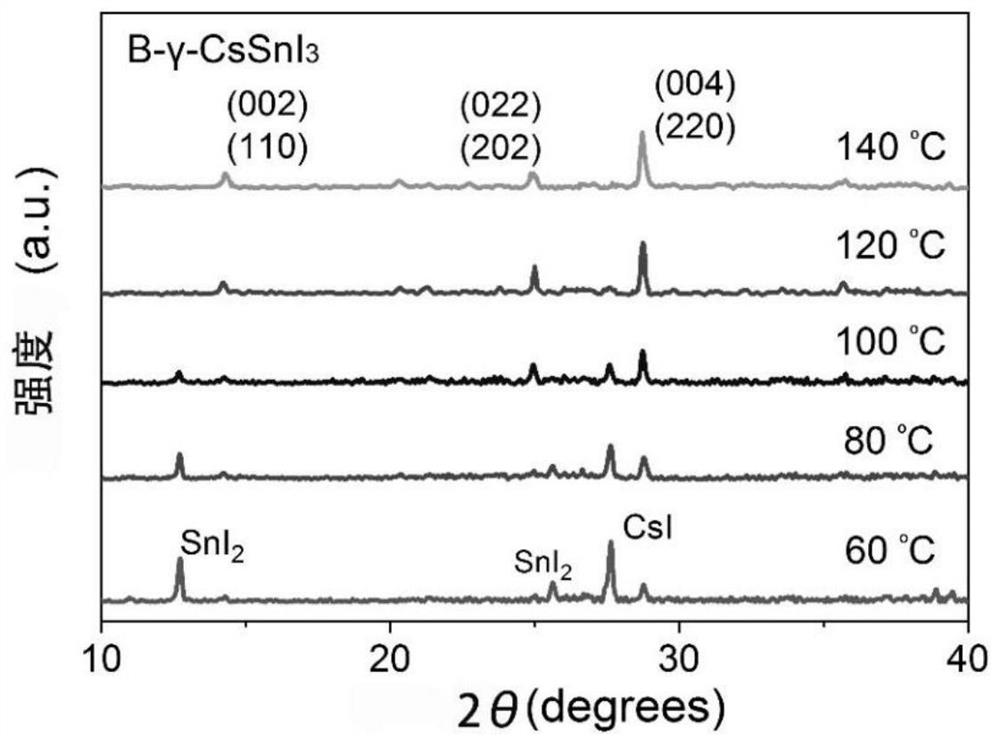

[0050] A method for preparing an efficient and stable inorganic lead-free perovskite solar cell, comprising the steps of:

[0051] (1) Partially etch the conductive surface of the ITO conductive glass. The etching method is as follows: add dilute hydrochloric acid with a concentration of 2mol / L to the surface of the ITO glass covered with half the area of zinc powder at room temperature, and the etching is completed after 5 minutes of reaction. Then, they were ultrasonically cleaned with detergent, acetone and ethanol at room temperature for 20 minutes, dried and placed in a UV-ozone processor for 30 minutes at room temperature to obtain an ITO conductive glass substrate with a thickness of 150 nm.

[0052] (2) Spin-coat 100 μL of PEDOT:PSS conductive coating (concentration 1.3-1.7%) on the ITO conductive glass substrate at a speed of 3000 rpm for 30 s using a homogenizer, then place it on a hot plate at 100 ° C and heat it in the air After 10 minutes, a PEDOT:PSS layer with...

Embodiment 2

[0061] A method for preparing an efficient and stable inorganic lead-free perovskite solar cell, as described in Example 1, the difference is:

[0062] The metal counter electrode layer is an Au layer; the preparation method is as follows: when the gas pressure is lower than 1*10 -5 Under the condition of Pa, Au is evaporated at an evaporation rate of 0.5nm / s and deposited on the BCP layer to obtain an Au counter electrode layer with a thickness of 50nm;

[0063] Other steps and conditions are consistent with Example 1.

Embodiment 3

[0065] A method for preparing an efficient and stable inorganic lead-free perovskite solar cell, as described in Example 1, the difference is:

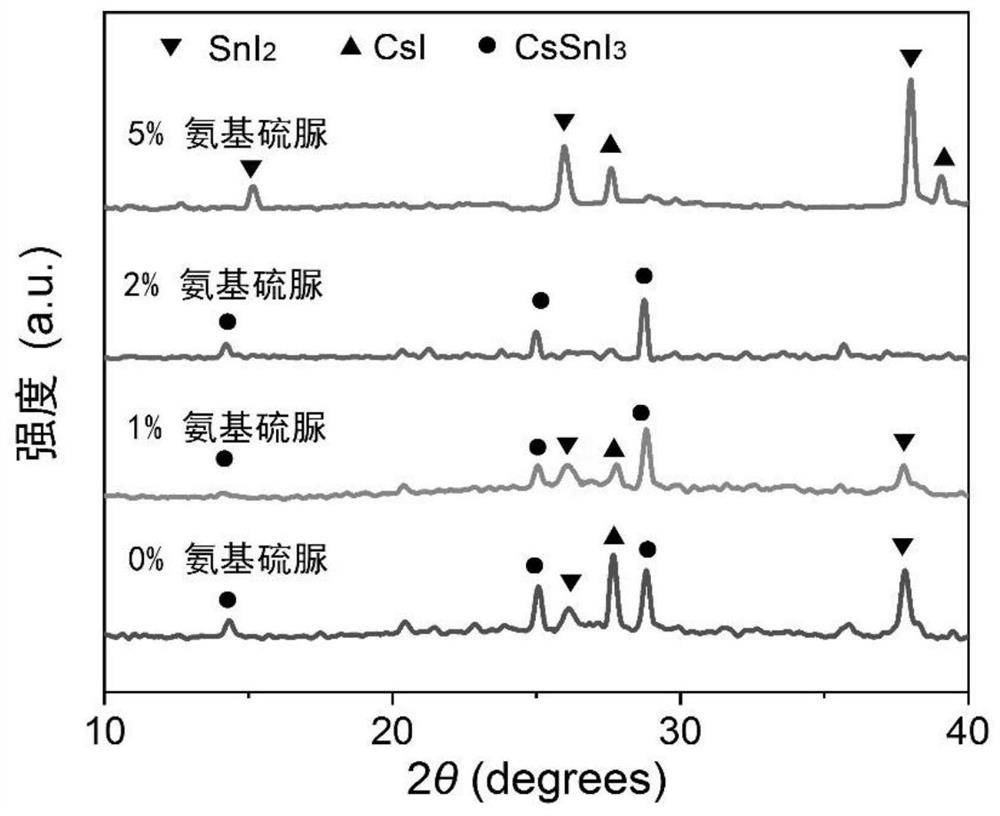

[0066] Step (3), thiosemicarbazide is replaced by thiourea, and the preparation method is as follows: the SnI of 1.2mmol 2 (purity is 99.99%), 0.02mmol of thiourea and 1mmol of CsI (purity is 99.9%) three precursors are respectively placed in three evaporation chambers of thermal evaporation equipment, in a vacuum less than 1*10 -5 Under Pa, first heat the SnI at 350°C 2 , keep the evaporation rate at 0.2nm / s until the sample is exhausted. Then, heat thiourea at 100°C, keep the evaporation rate at 0.2nm / s, and wait for the sample to be consumed. Finally, heat CsI at 600 °C, keep the evaporation rate at 0.5 nm / s, and wait until the sample is consumed. Transfer the deposited product from the vacuum thermal evaporation equipment to the heating plate, and anneal it at 120°C for 15 minutes to obtain an inorganic lead-free CsSnI with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com