FeSix embedded porous silicon composite material as well as preparation method and application thereof

A composite material and porous silicon technology, which is applied in the field of preparation of FeSix embedded porous silicon composite electrode, iron silicide embedded porous silicon composite material, can solve the problems of volume change, high energy consumption, and electrode performance degradation, and achieve the improvement of the first Coulombic efficiency , Relieve volume expansion, excellent long-term circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of FeSix embedding porous silicon composite material preparation method is characterized in that, comprises the steps:

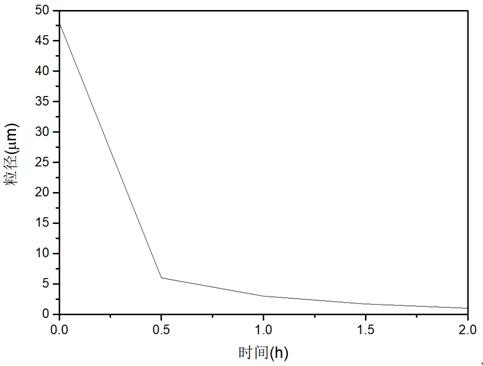

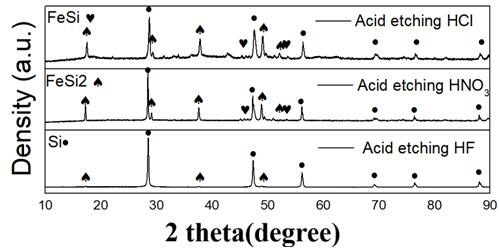

[0031] Step 1: Commercial ferrosilicon powder (200 mesh, mass fraction ratio Si:Fe=75:25) is ball milled with a ball mill at a speed of 400r / min for 1 hour to obtain ferrosilicon powder with uniform particle size, and the particle size is 1-3μm; The commercial magnesium powder and the ball-milled ferrosilicon powder are ground and mixed in a mortar according to the stoichiometric ratio of 1.5:1, and then placed in a crucible.

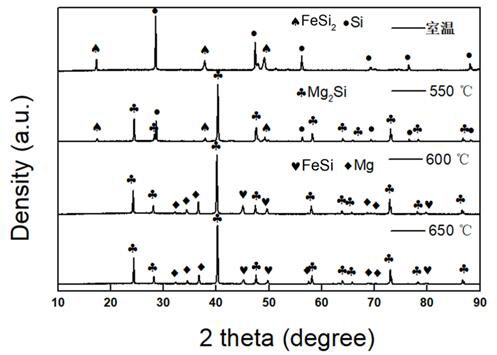

[0032] Step 2: put it into a tube furnace, heat it to 600°C at a heating rate of 5°C / min under an argon protective atmosphere and keep it warm for 6h to obtain the reacted mixture;

[0033] Step 3: Put the reacted mixture obtained in step 2 into a corundum crucible, then put it into a tube furnace and heat it to 750°C at a heating rate of 5°C / min for 6h under an ammonia atmosphere to obtain the reacted mixture;

[0034...

Embodiment 2

[0036] A kind of FeSix embedding porous silicon composite material preparation method is characterized in that, comprises the steps:

[0037] Step 1: Commercial ferrosilicon powder (200 mesh, mass fraction ratio Si:Fe=50:50) is ball milled with a ball mill at a speed of 400r / min for 1 hour to obtain ferrosilicon powder with uniform particle size, and the particle size is 1-3μm; The commercial magnesium powder and the ball-milled ferrosilicon powder are ground and mixed in a mortar according to the stoichiometric ratio of 1.5:1, and then placed in a crucible.

[0038] Step 2: put it into a tube furnace, heat it to 600°C at a heating rate of 5°C / min under an argon protective atmosphere and keep it warm for 6h to obtain the reacted mixture;

[0039] Step 3: Put the reacted mixture obtained in step 2 into a corundum crucible, then put it into a tube furnace and heat it to 750°C at a heating rate of 5°C / min for 6h under an ammonia atmosphere to obtain the reacted mixture;

[0040...

Embodiment 3

[0042] A kind of FeSix embedding porous silicon composite material preparation method is characterized in that, comprises the steps:

[0043] Step 1: Commercial ferrosilicon powder (200 mesh, mass fraction ratio Si:Fe=90:10) is ball milled with a ball mill at a speed of 400r / min for 1 hour to obtain ferrosilicon powder with uniform particle size, and the particle size is 1-3μm; The commercial magnesium powder and the ball-milled ferrosilicon powder are ground and mixed in a mortar according to the stoichiometric ratio of 1.5:1, and then placed in a crucible.

[0044] Step 2: put it into a tube furnace, heat it to 600°C at a heating rate of 5°C / min under an argon protective atmosphere and keep it warm for 6h to obtain the reacted mixture;

[0045] Step 3: Put the reacted mixture obtained in step 2 into a corundum crucible, then put it into a tube furnace and heat it to 750°C at a heating rate of 5°C / min for 6h under an ammonia atmosphere to obtain the reacted mixture;

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com