Preparation method and application of coumarin functionalized photoresponse adsorbent

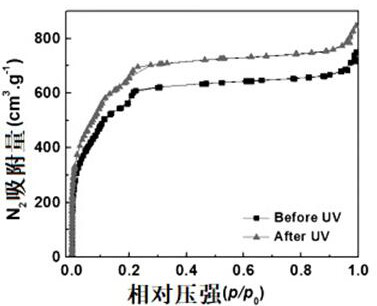

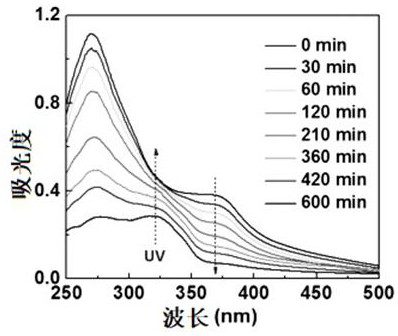

A coumarin, light-responsive technology, used in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve the problem of inability to modulate surface properties, and achieve the effect of increased adsorption capacity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

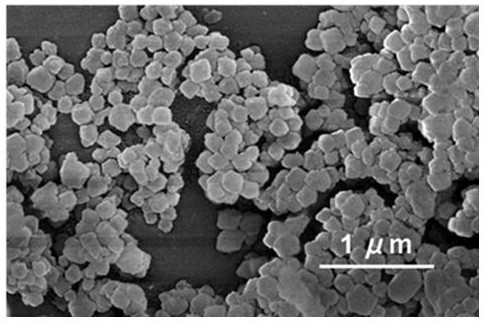

[0029] A preparation method of a coumarin-functionalized light-responsive adsorbent, comprising the following steps:

[0030] (1) To prepare the adsorbent carrier MIL-101-Cr, weigh 1.63kg of chromium nitrate nonahydrate and 0.7kg of terephthalic acid to dissolve in 20L of deionized water, then add 0.2kg of 40% hydrofluoric acid, and synthesize in hydrothermal React in the reactor at 180°C for 8 hours, cool to room temperature, filter, wash three times with N,N-dimethylformamide and ethanol, and dry. The product is the adsorbent carrier MIL-101-Cr:

[0031] (2) Deprotonate the coumarin molecules, weigh 0.049kg of coumarin molecules and dissolve them in 7L of methanol, weigh 0.0648kg of sodium methoxide and dissolve them in 20L of methanol, mix them, reflux at 67°C for 3 hours, and coumarin The deprotonation of the prime molecule is completed;

[0032] (3) Dissolve 0.196kg of the adsorbent carrier MIL-101-Cr in 3L of methanol and stir. In order to speed up the dissolution rate,...

Embodiment 2

[0037] A preparation method of a coumarin-functionalized light-responsive adsorbent, comprising the following steps:

[0038] (1) To prepare the adsorbent carrier MIL-101-Cr, weigh 1.63kg of chromium nitrate nonahydrate and 0.7kg of terephthalic acid to dissolve in 20L of deionized water, then add 0.2kg of 40% hydrofluoric acid, and synthesize in hydrothermal React in the reactor at 180°C for 8 hours, cool to room temperature, filter, wash with N,N-dimethylformamide and ethanol three times, and dry. The product is the adsorbent carrier MIL-101-Cr:

[0039] (2) Deprotonate the coumarin molecules, weigh 0.098kg of coumarin molecules and dissolve them in 20L of methanol, weigh 0.0648kg of sodium methoxide and dissolve them in 20L of methanol, mix them, reflux at 67°C for 3h, and coumarin The deprotonation of the prime molecule is completed;

[0040](3) Dissolve 0.196kg of the adsorbent carrier MIL-101-Cr in 3L of methanol and stir. In order to speed up the dissolution rate, heat...

Embodiment 3

[0045] A preparation method of a coumarin-functionalized light-responsive adsorbent, comprising the following steps:

[0046] (1) To prepare the adsorbent carrier MIL-101-Cr, weigh 1.63kg of chromium nitrate nonahydrate and 0.7kg of terephthalic acid to dissolve in 20L of deionized water, then add 0.2kg of 40% hydrofluoric acid, and synthesize in hydrothermal React in the reactor at 180°C for 8 hours, cool to room temperature, filter, wash with N,N-dimethylformamide and ethanol three times, and dry. The product is the adsorbent carrier MIL-101-Cr:

[0047] (2) Deprotonate the coumarin molecules, weigh 0.147kg of coumarin molecules and dissolve them in 7L of methanol, weigh 0.0648kg of sodium methoxide and dissolve them in 20L of methanol, mix them, reflux at 67°C for 3h, and coumarin The deprotonation of the prime molecule is completed;

[0048] (3) Dissolve 0.196kg of the adsorbent carrier MIL-101-Cr in 3L of methanol and stir. In order to speed up the dissolution rate, heat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap