A method for rapid preparation of ultra-thin epitaxial bismuth ferrite thin films based on microwave hydrothermal method

A technology of microwave hydrothermal method and bismuth ferrite, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of expensive equipment, high vacuum target materials, and no reports, etc., and achieve the reduction of electric energy and the reduction of chemical raw materials Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

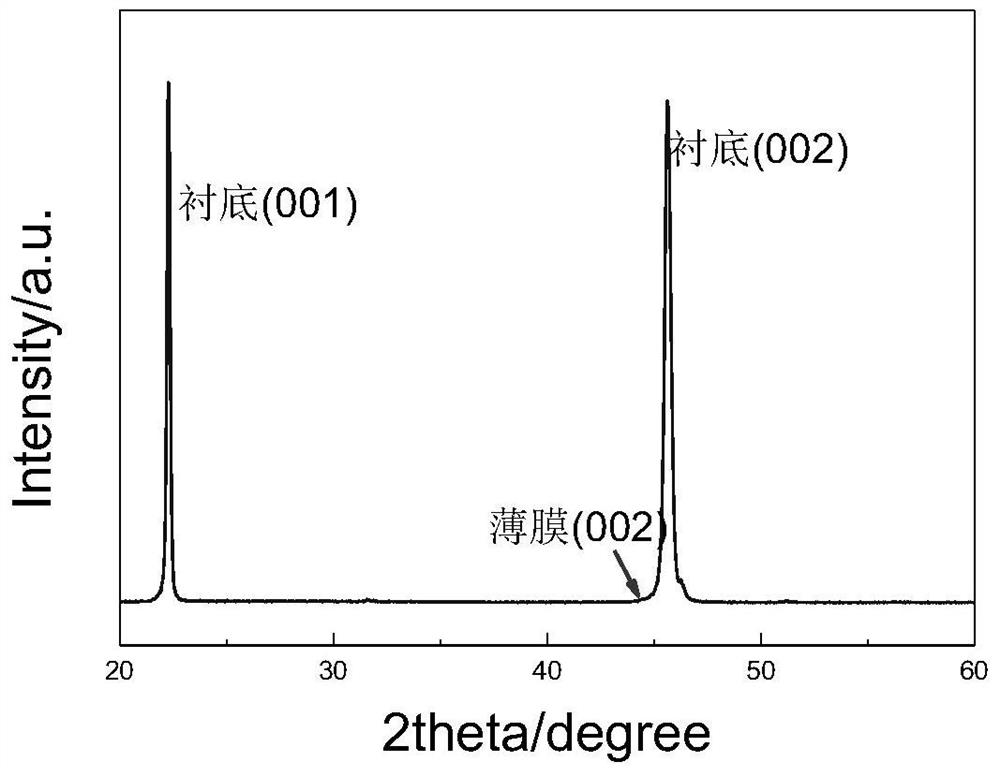

Image

Examples

Embodiment 1

[0015] Step 1. Put a 0.5mm×0.5mm strontium titanate single crystal substrate into a plasma cleaning machine, clean and activate for 10 minutes, the radio frequency power is 100W, and the frequency is 13.56Hz.

[0016] Step 2, take 0.404 ferric nitrate nonahydrate (Fe(NO) 3 ) 3 ·9H 2 O) and 0.485 g of bismuth nitrate nonahydrate (Bi(NO) 3 ) 3 ·5H 2 O), and 0.560g of KOH, dissolved in 27g of water, and stirred evenly to obtain a precursor suspension.

[0017] Step 3. Pour the suspension obtained in step 2 into the polytetrafluoroethylene reactor, then take out the activated substrate quickly, place the polished side down on the polytetrafluoroethylene support, put the support into the The height of the bottom polished surface from the bottom of the reaction kettle is 4 mm.

[0018] Step 4. Put the reaction kettle into a microwave hydrothermal synthesizer, heat it, and heat it to 140 degrees Celsius with a power of 300W within 8 minutes, then heat it to 180 degrees Celsius ...

Embodiment 2

[0021] Step 1. Put a 0.5mm×0.5mm doped strontium niobate titanate single crystal substrate into a plasma cleaning machine, clean and activate for 10 minutes, the radio frequency power is 100W, and the frequency is 13.56Hz.

[0022] Step 2: Dissolve 0.270g of ferric trichloride hexahydrate, 0.705g of bismuth sulfate, and 0.400g of NaOH in 27g of water and stir evenly to obtain a precursor suspension.

[0023] Step 3. Pour the suspension obtained in step 2 into the polytetrafluoroethylene reactor, then take out the activated substrate quickly, place the polished side down on the polytetrafluoroethylene support, put the support into the The height of the bottom polished surface from the bottom of the reaction kettle is 4 mm.

[0024] Step 4. Put the reaction kettle into a microwave hydrothermal synthesizer, heat it, and heat it to 140 degrees Celsius with a power of 300W within 8 minutes, then heat it to 180 degrees Celsius within 17 minutes and keep it warm to grow a film.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com