Metal base substrate

A technology of metal base and metal substrate, which is applied in the direction of metal pattern materials, circuit substrate materials, metal layered products, etc., can solve the problems of high solder stress, high thermal expansion rate, and difficulty in fully reducing stress, so as to prevent solder cracks , The effect of suppressing the occurrence of solder cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

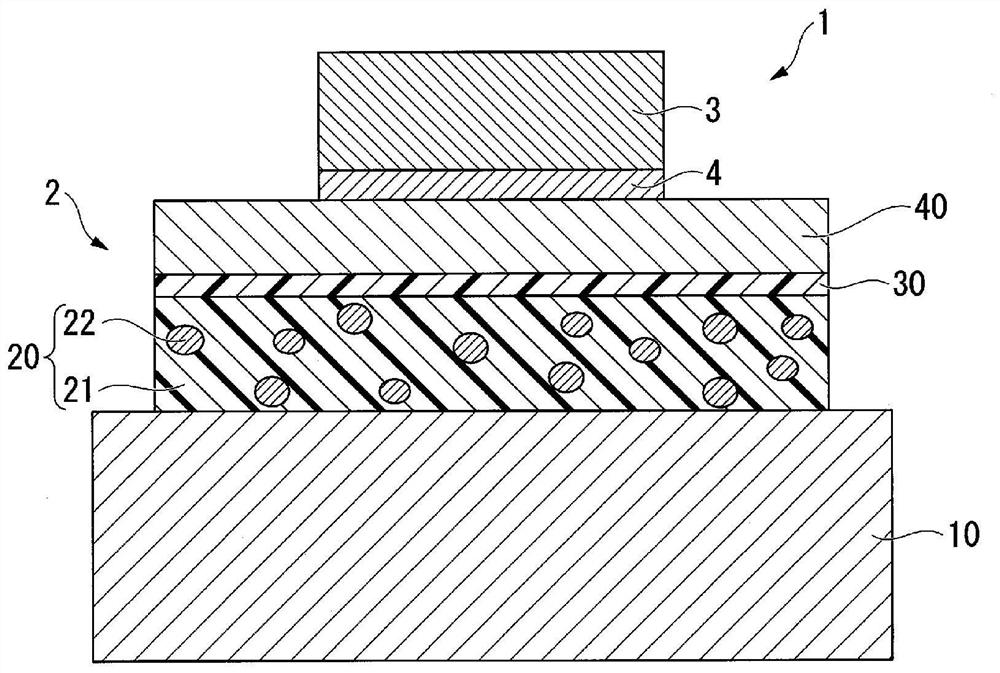

Image

Examples

Embodiment

[0054] Hereinafter, the effects of the present invention will be described through examples.

[0055] [Example 1 of the present invention]

[0056] 4,4'-Diaminodiphenyl ether and NMP (N-methyl-2-pyrrolidine) were placed in a 300 mL separable flask. The amount of NMP was adjusted so that the density|concentration of the obtained polyamic acid might become 40 mass %. After stirring at room temperature to completely dissolve 4,4'-diaminodiphenyl ether, a predetermined amount of tetracarboxylic dianhydride was added little by little so that the internal temperature did not exceed 30°C. Then, stirring was continued for 16 hours under a nitrogen atmosphere to prepare a polyamic acid (polyimide precursor) solution.

[0057] Alumina particles (average particle diameter: 0.5 μm) were prepared as ceramic particles (thermally conductive filler). The prepared 1.0 g of alumina particles and 10 g of NMP were mixed and subjected to ultrasonic treatment for 30 minutes to prepare an alumina...

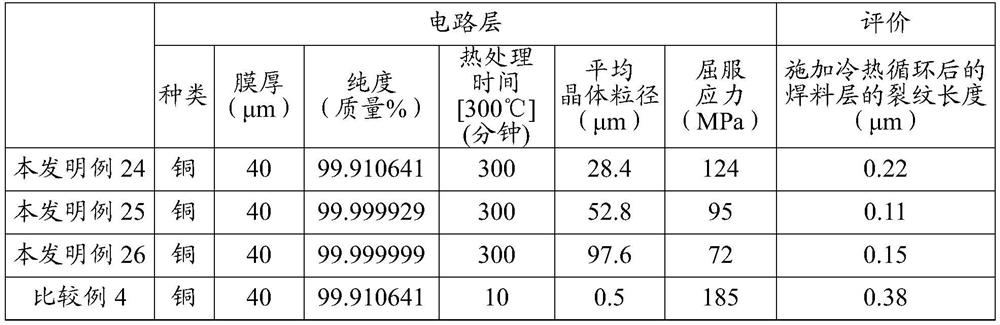

example 4

[0076] A metal base substrate was fabricated in the same manner as in Example 1 of the present invention, except that copper foil whose film thickness, purity, average grain size, and yield stress (0.2% yield strength) were the values shown in Table 2 below was used instead of aluminum foil. , and measure the crack length of the solder layer after applying the thermal cycle. The average crystal grain diameter and yield stress (0.2% yield stress) of copper foil were adjusted by heat-processing at the temperature of 300 degreeC for the heat-treatment time shown in following Table 2. In addition, regarding the purity of the copper foil, except that the impurity elements are Na, Mg, Si, Al, P, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Zn, Ga, Ge, Nb, Mo, Ru, Pd, Ag, In, Sn, Sb, Ba, Hf, W, Pt, Au, Pb, and Bi were measured in the same manner as the purity of aluminum foil. About the average crystal grain diameter of copper foil, it measured similarly to the average crystal grain diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com