Preparation method of self-cleaning anti-icing coating based on brush-shaped organic silicon

A self-cleaning, silicone technology, applied in the field of materials science, can solve the problems of insufficient mechanical properties and short durability, and achieve the effect of good low surface energy performance, short production cycle, and superior self-cleaning and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

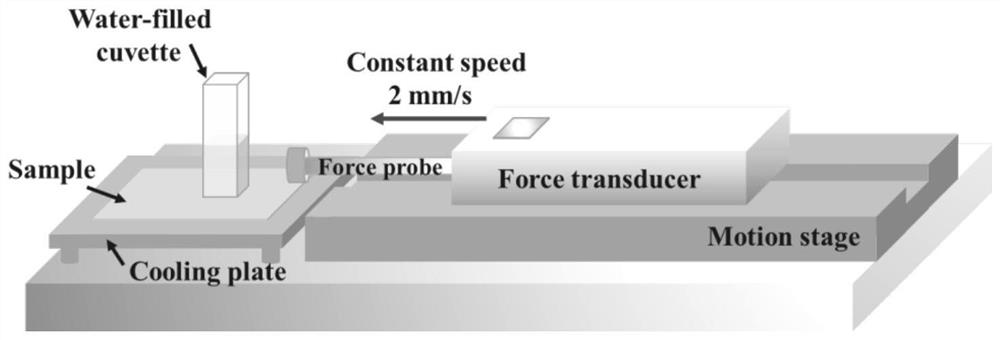

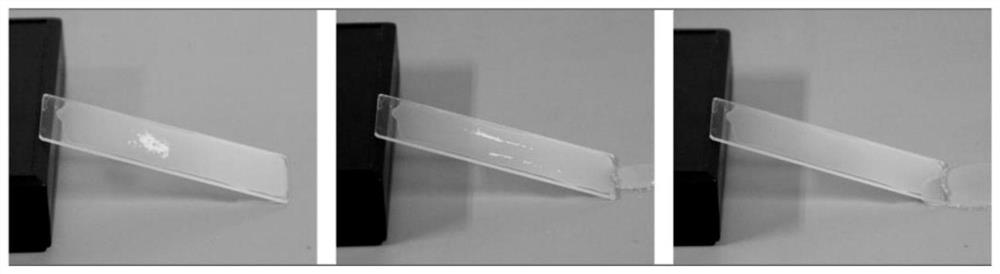

Method used

Image

Examples

Embodiment 1

[0032] Under the protection of nitrogen, 5.0ml of dioxane, 0.10mmol of acrylamide thiolactone, 0.10mmol of 3-mercapto-1-propanol and 0.50mL of triethylamine were added to the reaction vessel, and the mercapto-ene addition was carried out at room temperature. After 1 hour, the modified thiolactone was obtained; 0.05 mmol of diamine and 0.10 mmol of siloxane were added to the above reaction vessel in sequence, and the amine group nucleophilic ring-opening reaction and sulfhydryl click reaction of the thiolactone were carried out in sequence. After reacting for 6 hours, the siloxane block was obtained; under nitrogen protection, PTMEG 12mmol, IPDI 6mmol, DBTDL 50μL and BDO 6mmol (dissolved in 5mL DOX) were successively added to the reaction vessel and reacted at 60°C for 4h to obtain the resin matrix; Take 1g of the above resin matrix and dissolve it in 3mL DOX to prepare a solution with a concentration of 25%, spread it on the substrate by the salivation method, place it in a bla...

Embodiment 2

[0036]Under the protection of nitrogen, 5.0ml of dioxane, 0.20mmol of acrylamide thiolactone, 0.20mmol of 3-mercapto-1-propanol and 1.0mL of triethylamine were added to the reaction vessel, and the mercapto-ene addition was carried out at room temperature. After 3 hours, the modified thiolactone was obtained; 0.10 mmol of diamine and 0.20 mmol of siloxane were added to the above reaction vessel, and the amine group nucleophilic ring-opening reaction and sulfhydryl click reaction of the thiolactone were sequentially carried out. , the siloxane block was obtained after 18 hours of reaction; under nitrogen protection, PTMEG 8.0mmmol, IPDI 2.0mmol, DBTDL 150μL and BDO 6.0mmol (dissolved in 5mL DOX) were successively added to the reaction vessel and reacted for 6 hours at 80°C to obtain Resin matrix: Dissolve 1g of the above resin matrix in 4mL DOX to prepare a solution with a concentration of 20%, spread it on the substrate by the salivation method, place it in a blast oven, and he...

Embodiment 3

[0040] Under the protection of nitrogen, 5.0ml of dioxane, 0.10mmol of acrylamide thiolactone, 0.10mmol of 3-mercapto-1-propanol and 0.50mL of triethylamine were added to the reaction vessel, and the mercapto-ene addition was carried out at room temperature. After 1 hour, the modified thiolactone was obtained; 0.05 mmol of diamine and 0.10 mmol of siloxane were added to the above reaction vessel in sequence, and the amine group nucleophilic ring-opening reaction and sulfhydryl click reaction of the thiolactone were carried out in sequence. After reacting for 6 hours, the siloxane block was obtained; under the protection of nitrogen, sequentially add PTMEG 16mmmol, IPDI 4mmol, DBTDL 50μL and BDO 12mmol (dissolved in 5mLDOX) in the reaction vessel and react at 70°C for 10h to obtain the resin matrix; Take 1g of the resin matrix and dissolve it in 2mL DOX to prepare a solution with a concentration of 33%, spread it on the substrate by the salivation method, place it in a blast ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com