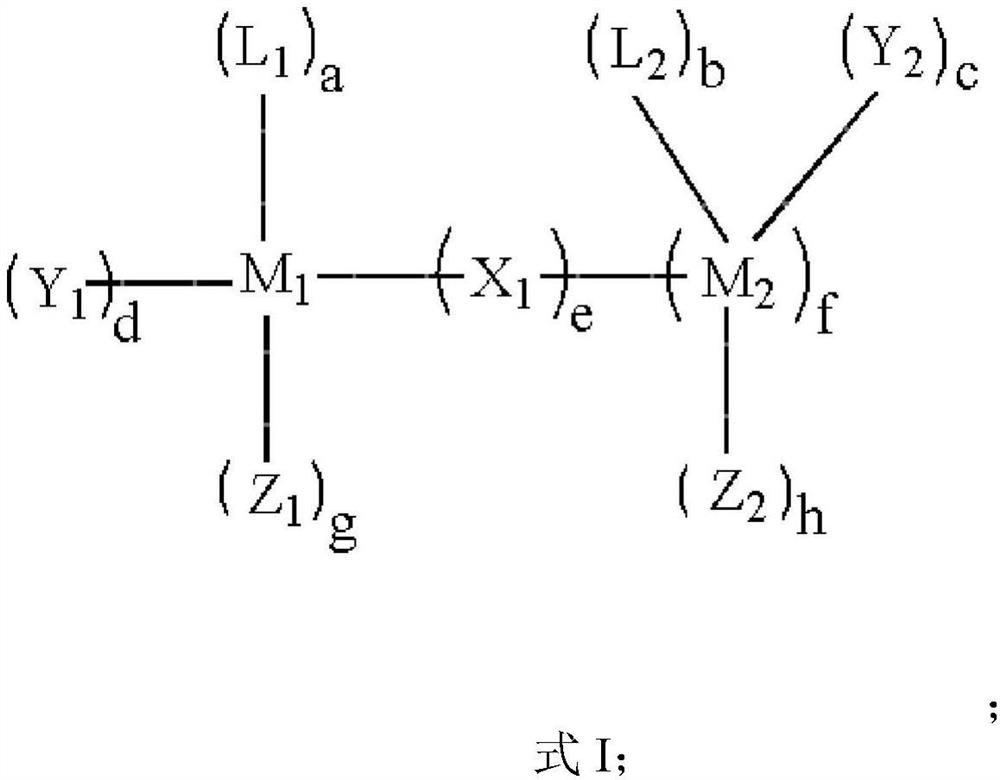

Phosphorus-containing flame retardant with epoxy group as well as preparation method and application of flame retardant

An epoxy-based, flame retardant technology, applied in the field of flame retardants, can solve the problems of coating adhesion decline, environmental pollution, etc., and achieve the effects of reduced viscosity, high adhesion stability, and high flame retardant stability

- Summary

- Abstract

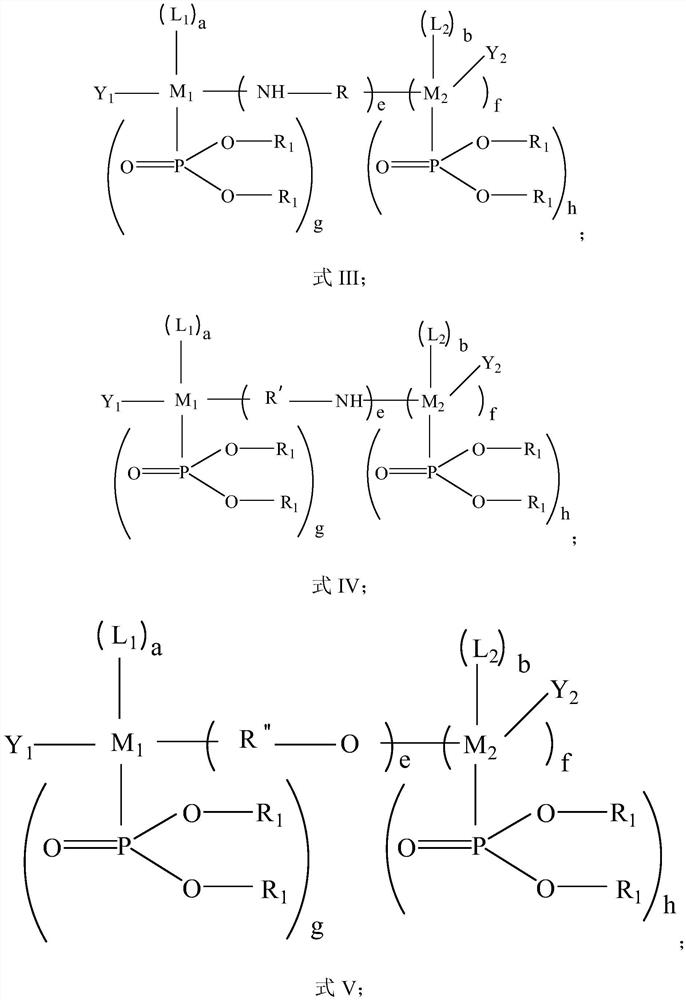

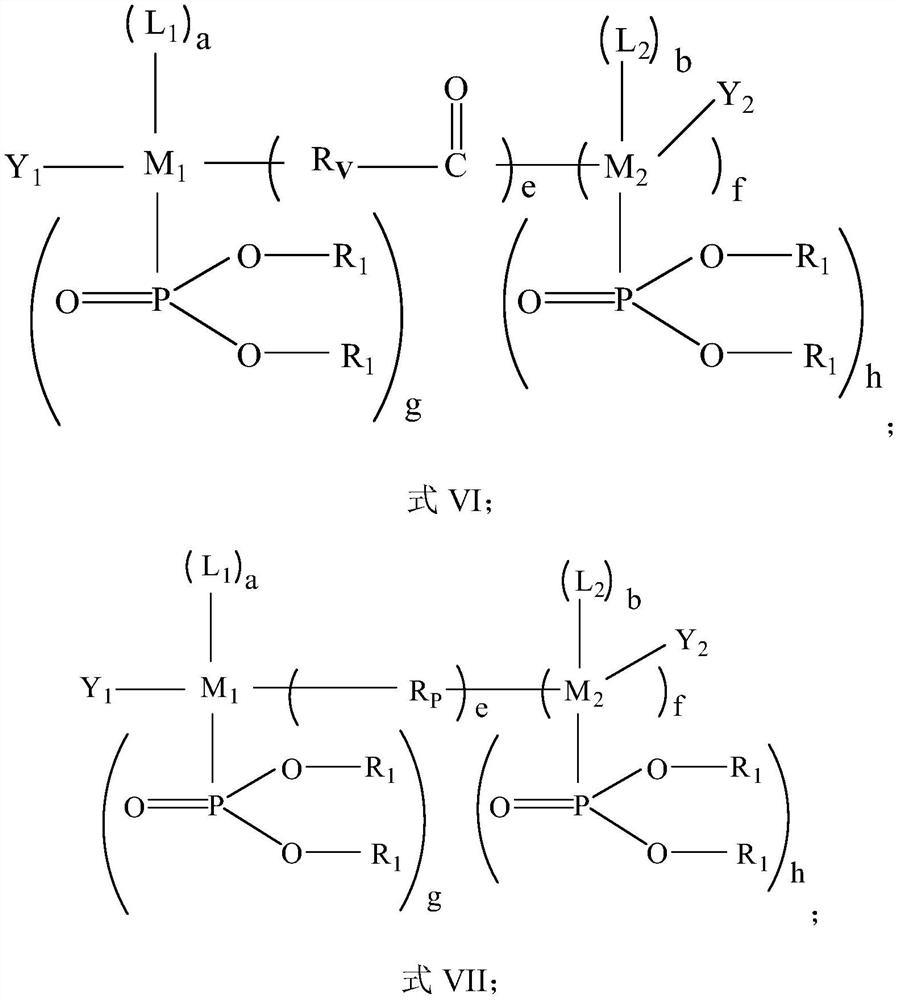

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] A phosphorus-containing flame retardant with an epoxy group, the structure is as follows:

[0070]

[0071] The preparation method is as follows:

[0072] (1) Under a nitrogen atmosphere, put 50mL of glacial acetic acid, 1mol of dimethyl phosphite and 1mol of methacrylic acid into a three-port 200mL glass reactor with a stirring device, and dissolve 1mmol of Pb catalyst in 20mL of glacial acetic acid, then added dropwise to the above reaction system, reacted at 60°C for 12h, then added saturated sodium carbonate solution, separated the water phase with a separatory funnel, dehydrated under reduced pressure and washed with water until neutral, dried After obtaining intermediate 1;

[0073](2) Add the intermediate 1 obtained in step 1, 2 mol of epichlorohydrin and 0.02 mol of triethylbenzyl ammonium chloride into a 1000 mL three-necked glass flask, and simultaneously add 100 mL of 40 wt % sodium hydroxide aqueous solution dropwise, and heat the mixture at 110° C. Sti...

preparation example 2

[0076] A phosphorus-containing flame retardant with an epoxy group, the structure is as follows:

[0077]

[0078] The preparation method is as follows:

[0079] (1) Under a nitrogen atmosphere, put 50mL of glacial acetic acid, 1mol of dimethyl phosphite and 1mol of acrylic acid into a three-port 200mL glass reactor with a stirring device, and dissolve 1mmol of Pb catalyst in 20mL of ice at 60°C under stirring conditions. Acetic acid, then added dropwise to the above reaction system, reacted at 60°C for 12h, then added saturated sodium carbonate solution, separated the water phase with a separatory funnel, dehydrated under reduced pressure and washed with water until neutral, dried to obtain Intermediate 1;

[0080] (2) Add the intermediate 1 obtained in step 1, 2 mol of epichlorohydrin and 0.02 mol of triethylbenzyl ammonium chloride into a 1000 mL three-necked glass flask, and simultaneously add 100 mL of 40 wt % sodium hydroxide aqueous solution dropwise, and heat the m...

preparation example 3

[0083] A phosphorus-containing flame retardant with an epoxy group, the structure is as follows:

[0084]

[0085] (1) Under a nitrogen atmosphere, put 50mL of glacial acetic acid, 1mol of dimethyl phosphite and 1mol of tetrahydrophthalic anhydride into a three-port 200mL glass reactor with a stirring device, and mix 1mmol of The Pb catalyst was dissolved in 20mL of glacial acetic acid, and then added dropwise to the above reaction system, reacted at 60°C for 12h, then added saturated sodium carbonate solution, separated the water phase with a separatory funnel, dehydrated under reduced pressure and washed with water until Neutral, intermediate 1 is obtained after drying;

[0086] (2) Add the intermediate 1 obtained in step 1, 3 mol of epichlorohydrin and 0.04 mol of triethylbenzyl ammonium chloride into a 1000 mL three-necked glass flask, and simultaneously add 150 mL of 40 wt % sodium hydroxide aqueous solution dropwise, and heat the mixture at 110° C. Stir and react for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com