Method for preparing electric response drug control system by zinc oxide nanoparticle-mediated high-toughness hydrogel

A zinc oxide nano and hydrogel technology, which is applied in electrotherapy, pharmaceutical formulations, conductive adhesives, etc., can solve the problems of single response, widening, and easy pollution, and achieve good chemical stability, simple process, The effect of high efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

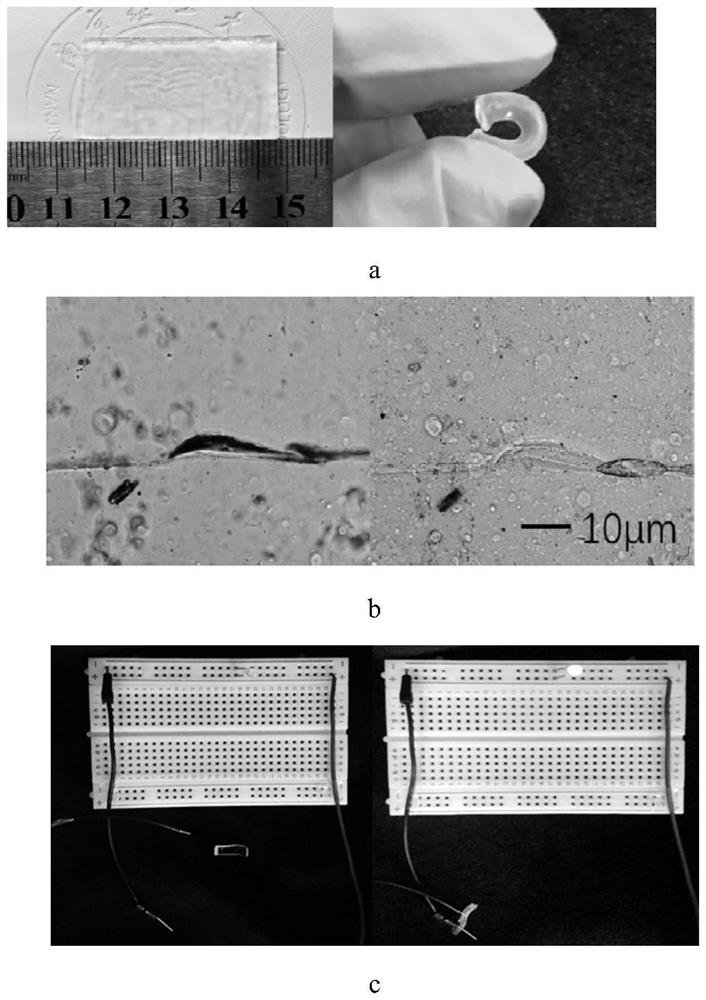

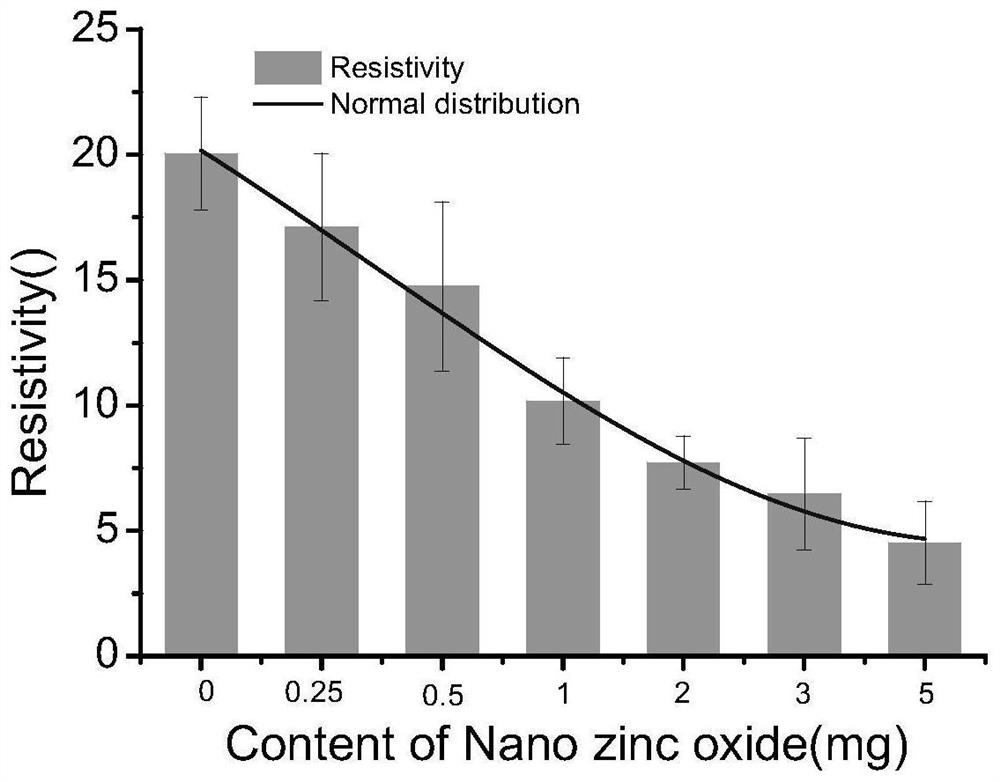

[0030] 1 mg of rod-shaped nano-zinc oxide particles were sonicated for 1 h to make them highly dispersed in a mixed solution of ethanol and water with a volume ratio of 9:1. Dissolve 30 mg of agar powder in the mixed solution, place it on a thermostatic mixer at 95° C. and stir at 1000 r / min at high speed for 2-3 hours, and wait for it to swell completely. Add 600 mL of N-hydroxyethylacrylamide monomer (HEAA) and an appropriate amount of photoinitiator. Then, stir at a constant temperature and high speed at a temperature of 40°C and a rotation speed of 1000r / min until the solution is clear and transparent. The obtained pregel solution is subjected to light polymerization. Finally, the pregel solution is first poured into a mold and covered with a PET film, and the wavelength is 365nm. 1. An ultraviolet lamp with a power of 10w was placed at a distance of 6cm above the pre-gel solution, and the light reaction was carried out for 0.5h to obtain a high-toughness hydrogel mediated...

Embodiment 2

[0032] 2 mg of rod-shaped nano-zinc oxide particles were sonicated for 1 h to make them highly dispersed in a mixed solution of ethanol and water with a volume ratio of 9:1. Dissolve 30 mg of agar powder in the mixed solution, place it on a thermostatic mixer at 95° C. and stir at 1000 r / min at high speed for 2-3 hours, and wait for it to swell completely. Add 700 mL of N-hydroxyethylacrylamide monomer (HEAA) and an appropriate amount of photoinitiator. Then, stir at a constant temperature and high speed at a temperature of 40°C and a rotation speed of 1000r / min until the solution is clear and transparent. The obtained pregel solution is subjected to light polymerization. Finally, the pregel solution is first poured into a mold and covered with a PET film, and the wavelength is 365nm. 1. An ultraviolet lamp with a power of 10w was placed at a distance of 6cm above the pregel solution, and the light reaction was carried out for 0.5h to obtain agar-zinc oxide nanoparticles / p(HEA...

Embodiment 3

[0034] 5 mg of rod-shaped nano-zinc oxide particles were sonicated for 1 h to make them highly dispersed in a mixed solution of ethanol and water with a volume ratio of 9:1. Dissolve 30 mg of agar powder in the mixed solution, place it on a thermostatic mixer at 95° C. and stir at 1000 r / min at high speed for 2-3 hours, and wait for it to swell completely. Add 600 mL of N-hydroxyethylacrylamide monomer (HEAA) and an appropriate amount of photoinitiator. Then, stir at a constant temperature and high speed at a temperature of 40°C and a rotation speed of 1000r / min until the solution is clear and transparent. The obtained pregel solution is subjected to light polymerization. Finally, the pregel solution is first poured into a mold and covered with a PET film, and the wavelength is 365nm. 1. An ultraviolet lamp with a power of 10w was placed at a distance of 6cm above the pre-gel solution, and the light reaction was carried out for 0.5h to obtain a high-toughness hydrogel mediated...

PUM

| Property | Measurement | Unit |

|---|---|---|

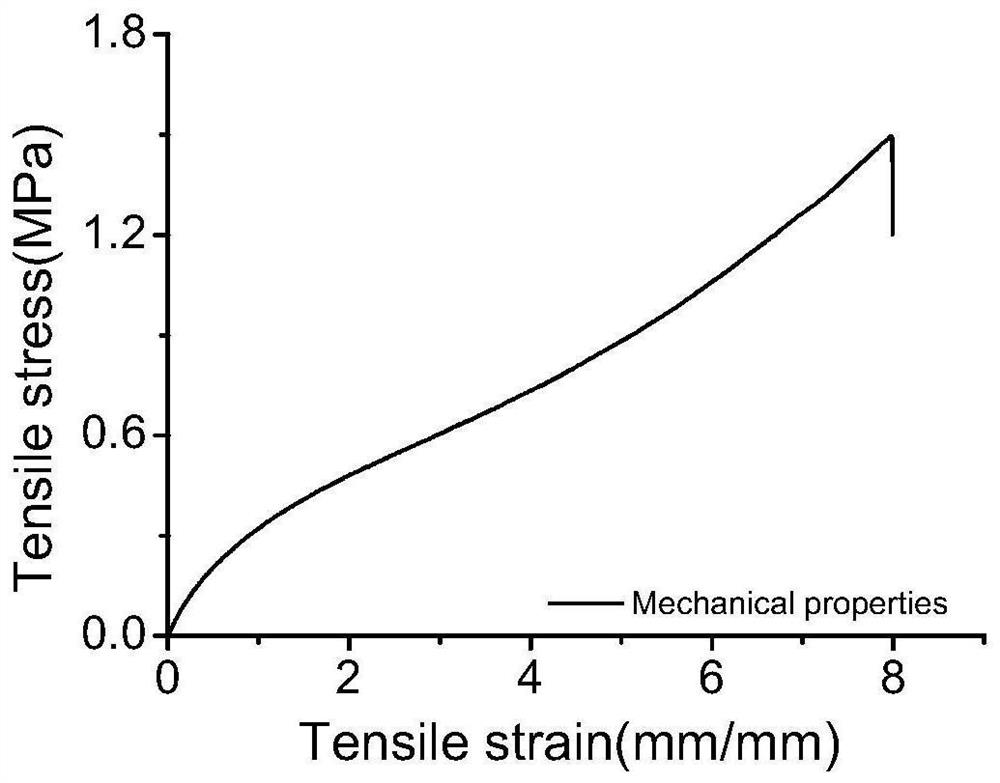

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com