A metal selenium sulfide nanocrystal@porous carbon sphere material and its preparation and application in lithium metal batteries

A technology of porous carbon and sulfide, applied in the direction of lithium batteries, battery electrodes, active material electrodes, etc., can solve the problems of poor electrical performance and cycle performance, achieve excellent performance, solve uneven lithium deposition, improve capacity and cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

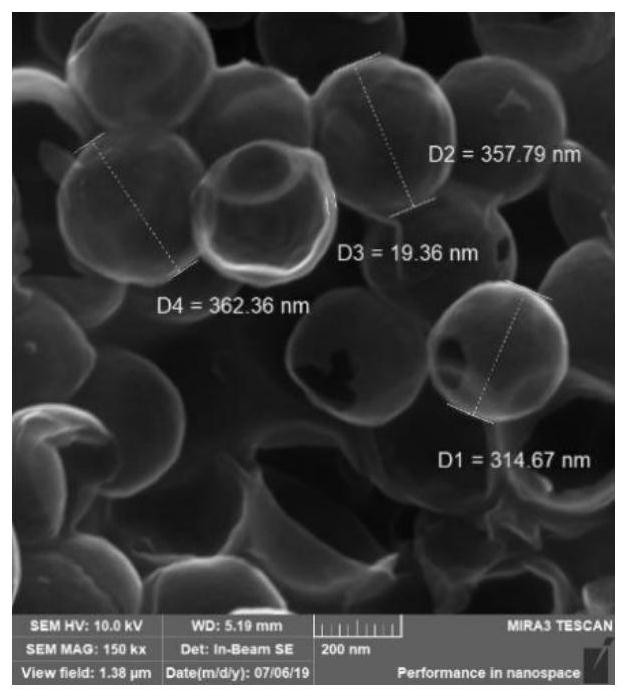

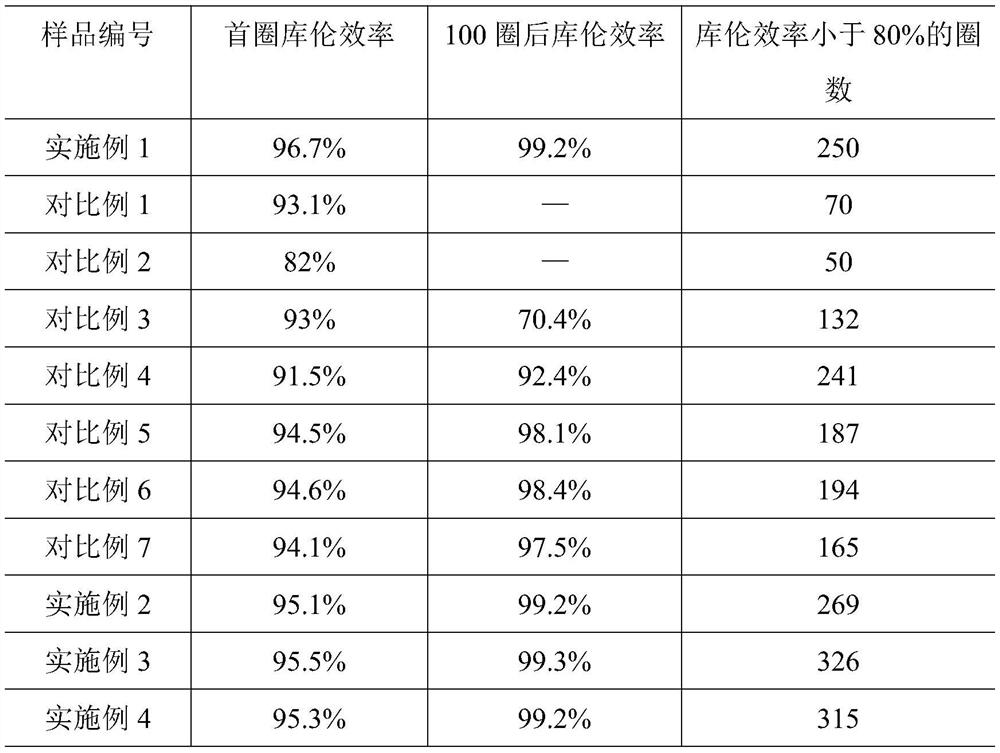

Embodiment 1

[0053] 0.12g porous carbon spheres (specific surface area 100m 2 / g, the carbon wall thickness is 5nm, and the internal cavity volume accounts for 90% of the total volume), 2.38g magnesium selenide powder, 50mL deionized water are mixed and then added in the hydrothermal reaction kettle, kept at 180 ℃ for 80 hours, and the The material was cleaned, filtered, and dried to obtain magnesium selenide@porous carbon spheres, and then the elemental sulfur was used as the sulfur source (the dosage was 3.2g), and sulfuration and doping were carried out in a dual-temperature zone tube furnace. The temperature of the sulfur source was 200°C. The temperature of the sample area (the temperature of the magnesium selenide@porous carbon sphere area, that is, the vulcanization temperature) is 250°C, the heating rate is 3°C / min, the holding time is 30min, and the cooling rate is 5°C / min, the obtained is the loaded selenium vulcanization Magnesium nanoparticles (MgS 0.16 Se 0.84 ) porous carbo...

Embodiment 2

[0072] Full battery case:

[0073] 0.3 porous carbon spheres (specific surface area 150m 2 / g, the carbon wall thickness is 25nm, and the internal cavity volume accounts for 78% of the total volume), 0.81g zinc selenide powder, 60mL deionized water are mixed and then added in the hydrothermal reaction kettle, at 160 ℃ for 75 hours, the This material is cleaned, filtered, and dried to obtain zinc selenide@porous carbon spheres. Elemental sulfur is used as the sulfur source. Sulfur doping is carried out in a dual-temperature zone tube furnace. The temperature is 200°C, the heating rate is 1°C / min, the holding time is 550min, and the cooling rate is 3°C / min. 0.81 Se 0.19 ) porous carbon sphere material (ZnS 0.81 Se 0.19 @ porous carbon spheres). Then it is mixed with polyvinylidene fluoride at a mass ratio of 9:1, slurried with NMP, and coated on copper foil (10 μm in thickness), with a coating thickness of 20 μm. Then deposit 50mAh / cm into the hollow carbon sphere chamber ...

Embodiment 3

[0075] 0.3g porous carbon spheres (specific surface area 146m 2 / g, the thickness of the carbon wall is 12nm, and the volume of the internal cavity accounts for 81% of the total volume), 2.77g of indium selenide powder, 55mL of deionized water are mixed and then added to the hydrothermal reactor, kept at 170°C for 72 hours, and the The material was cleaned, filtered, and dried, and sulfur-doped in a dual-temperature zone tube furnace. The temperature of the sulfur source was 250°C, the temperature of the sample area was 200°C, the heating rate was 3°C / min, the holding time was 450min, and the cooling rate was 6°C. / min, the resulting loaded selenium sulfide nanoparticles (In 2 (S 0.74 Se 0.26 ) 3 ) of porous carbon spheres. Then it is mixed with polyvinylidene fluoride at a mass ratio of 9:1, slurried with NMP, and coated on copper foil (10 μm in thickness), with a coating thickness of 50 μm. Then deposit 50mAh / cm into the porous carbon sphere chamber by electrochemical d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com