High-energy-storage power battery and preparation method

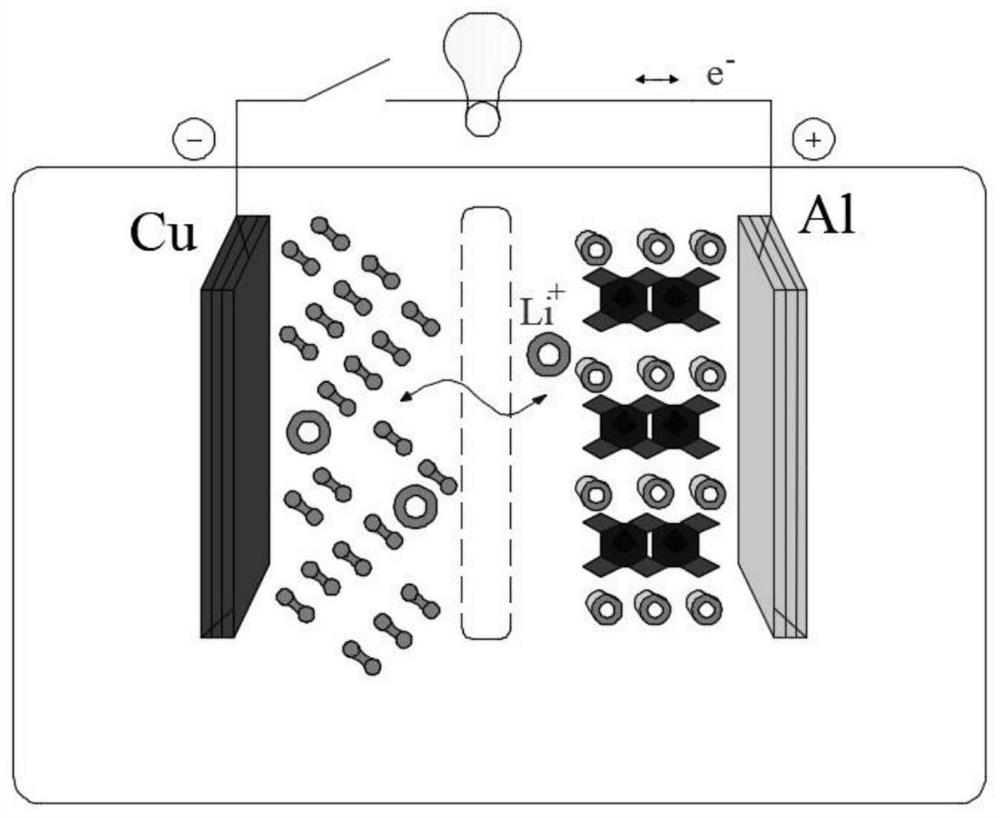

A power battery and high energy storage technology, which is applied in the field of electrochemistry, can solve the problems of volume expansion, the first charge and discharge efficiency has not been effectively improved, and achieve the effect of high specific energy, excellent cycle life, and increased charge and discharge cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

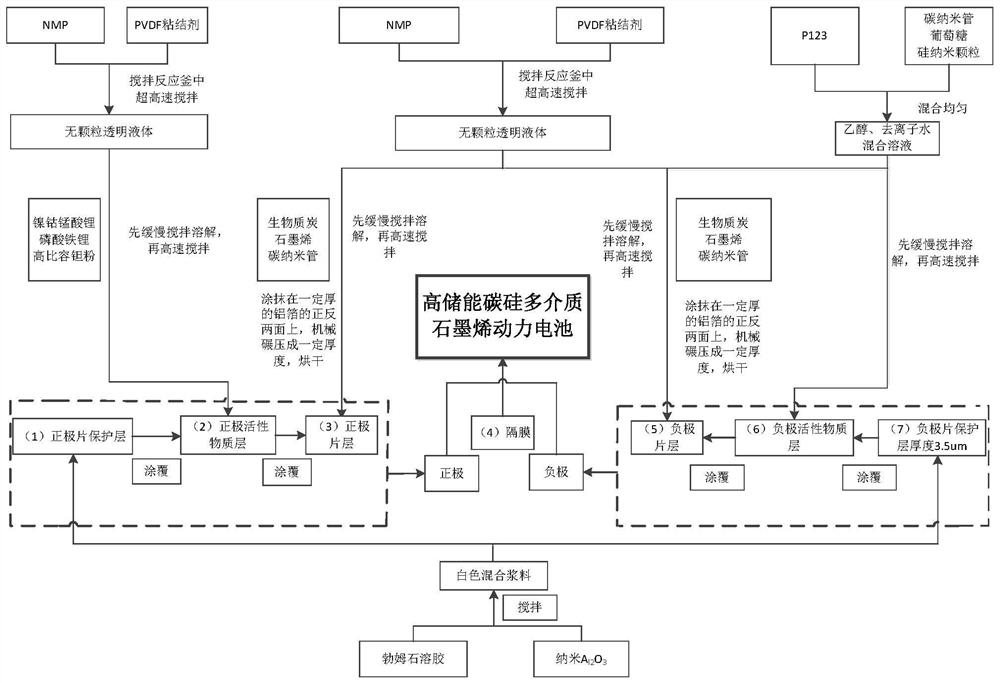

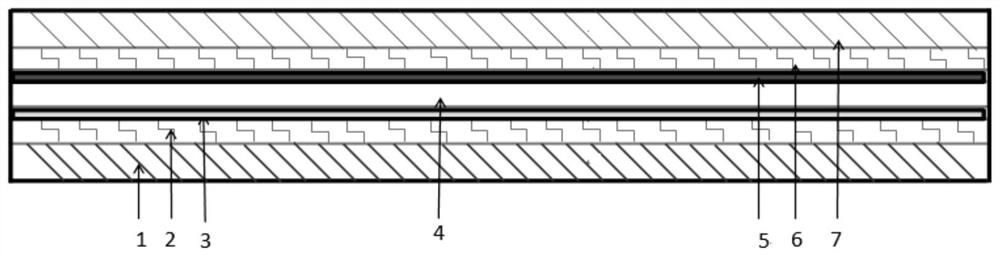

[0049] The preparation steps of the power battery of the present invention are as follows:

[0050] Step 1: Prepare the positive electrode part. Specifically include the following steps:

[0051] Step 11: The step of preparing the positive electrode sheet. The raw materials used in the preparation of positive electrodes mainly include: N-methylpyrrolidone (NMP), polyvinylidene fluoride (PVDF), carbon nanotubes, activated carbon, graphene, and aluminum foil.

[0052] Step 111: Prepare PVDF binder: dry a certain amount of PVDF powder in a vacuum oven at 80°C for 2 hours to remove moisture, then mix it with a certain amount of NMP, and stir at 60°C for 1 hour to form a transparent gel binder.

[0053] Step 112: Aluminum foil with a thickness of 15 μm is used as the matrix material when preparing the positive electrode sheet, and the carbon composite material is used as a reinforcement material to enhance the discharge performance of the positive electrode. When preparing, fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com