A kind of lithium battery electrolyte additive, electrolyte and lithium battery

An electrolyte additive, lithium battery technology, applied in the field of electrolyte and lithium battery, lithium battery electrolyte additive, can solve the problem that the battery is prone to bulging, affect the cycle life and safety performance of the lithium ion battery, and accelerate the decomposition of lithium in the anolyte solution. Dendrite growth and other problems, to achieve good hygroscopicity, increase solid content, and improve the effect of cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

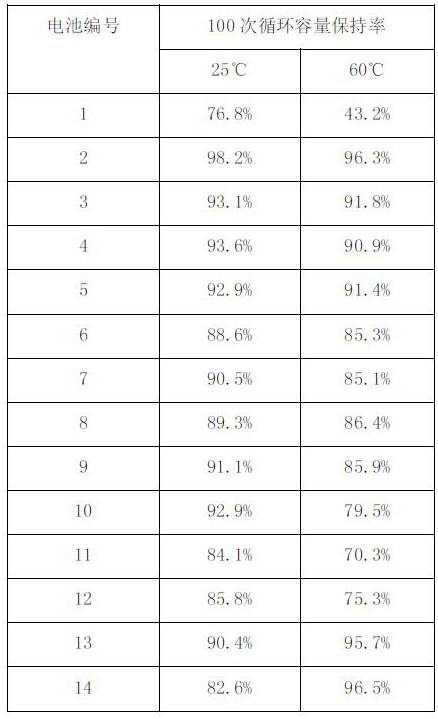

Image

Examples

Embodiment 1

[0033] Preparation of lithium battery electrolyte additives: (1) Mix urethane acrylate and acrylic acid monomers at a mass ratio of 1:1; (2) Add 5% paraffin and 2% diatomaceous earth to the mixture in step (1) Mix well; (3) Add 2,2-dimethoxy-2-phenylacetophenone (3% of the total mass of urethane acrylate and acrylic acid monomer) and graphite powder to the mixture obtained in step (2) 0.1%, mix uniformly and then granulate; (4) Add 1% of the lithium halide-diatomite-graphite mixture to the product obtained after step (3) and mix uniformly (to make the lithium halide-diatomite-graphite mixture adhere to on the surface of the particles); (5) cured under ultraviolet light to obtain the lithium battery electrolyte additive.

[0034] Among them: (1) The amount of each raw material mentioned above is calculated based on the total mass of urethane acrylate and acrylic acid monomer;

[0035] (2) The above steps (1)-(4) are all carried out under dark conditions, and steps (3)-(4) shou...

Embodiment 2

[0038] Preparation of lithium battery electrolyte additives: (1) Mix polyurethane acrylate and acrylic acid monomers at a mass ratio of 1:1; (2) Add 3% paraffin and 0.5% diatomaceous earth to the mixture in step (1) Mix well; (3) Add 2,2-dimethoxy-2-phenylacetophenone (4% of the total mass of polyurethane acrylate and acrylic acid monomer) and graphite powder to the mixture obtained from step (2) (4) Add 0.5% of the lithium halide-diatomaceous earth-graphite mixture to the product obtained after step (3) and mix uniformly (to make the lithium halide-diatomite-graphite mixture adhere to on the surface of the particles); (5) cured under ultraviolet light to obtain the lithium battery electrolyte additive.

[0039] Among them: (1) The amount of each raw material mentioned above is calculated based on the total mass of urethane acrylate and acrylic acid monomer;

[0040] (2) The above steps (1)-(4) are all carried out under dark conditions, and steps (3)-(4) should be completed i...

Embodiment 3

[0043]Preparation of lithium battery electrolyte additives: (1) Mix polyurethane acrylate and acrylic acid monomers at a mass ratio of 1:1; (2) Add 8% paraffin and 1.5% diatomaceous earth to the mixture in step (1) Mix well; (3) Add 2,2-dimethoxy-2-phenylacetophenone (5% of the total mass of polyurethane acrylate and acrylic acid monomer) and graphite powder to the mixture obtained from step (2) 0.2%, mix uniformly and then granulate; (4) Add 1.5% of the lithium halide-diatomite-graphite mixture to the product obtained after step (3) and mix uniformly (to make the lithium halide-diatomite-graphite mixture adhere to on the surface of the particles); (5) cured under ultraviolet light to obtain the lithium battery electrolyte additive.

[0044] Among them: (1) The amount of each raw material mentioned above is calculated based on the total mass of urethane acrylate and acrylic acid monomer;

[0045] (2) The above steps (1)-(4) are all carried out under dark conditions, and steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com