Method for extracting and separating trivalent lanthanide and/ or actinide ions by using phenanthroline phosphorus oxide

A technology of o-phenanthroline and phosphorus oxide, which is used in the field of nuclear fuel cycle and waste liquid treatment, can solve the problem that the distribution ratio of trivalent lanthanide and actinide is not high, and it is not suitable for the co-separation process of trivalent lanthanide and actinide. and other problems, to achieve the effect of good application prospect, fast extraction rate and strong extraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of embodiment 1 o-phenanthroline phosphorus oxide BuPh-PhenPO

[0063]

[0064] Using 2,9-dichloro-1,10-phenanthroline (2,9-dichloro-1,10-phenanthroline) as the initial reactant and the intermediate product butylphenylphosphine oxide in anhydrous toluene solvent, Under argon atmosphere, fully dissolve and mix according to the mass ratio of substances (1:2.5~1:3.0), and add K under the catalysis of palladium acetate and dppf 2 CO 3 The reflux reaction was carried out for about 7 hours, and the reaction progress was tracked by TLC thin-layer chromatography until the raw materials were completely reacted. After the reaction mixture was cooled, the solvent was removed by a rotary evaporator to obtain a crude product, and finally the obtained crude product was separated and purified by silica gel column chromatography to obtain the product BuPh-PhenPO.

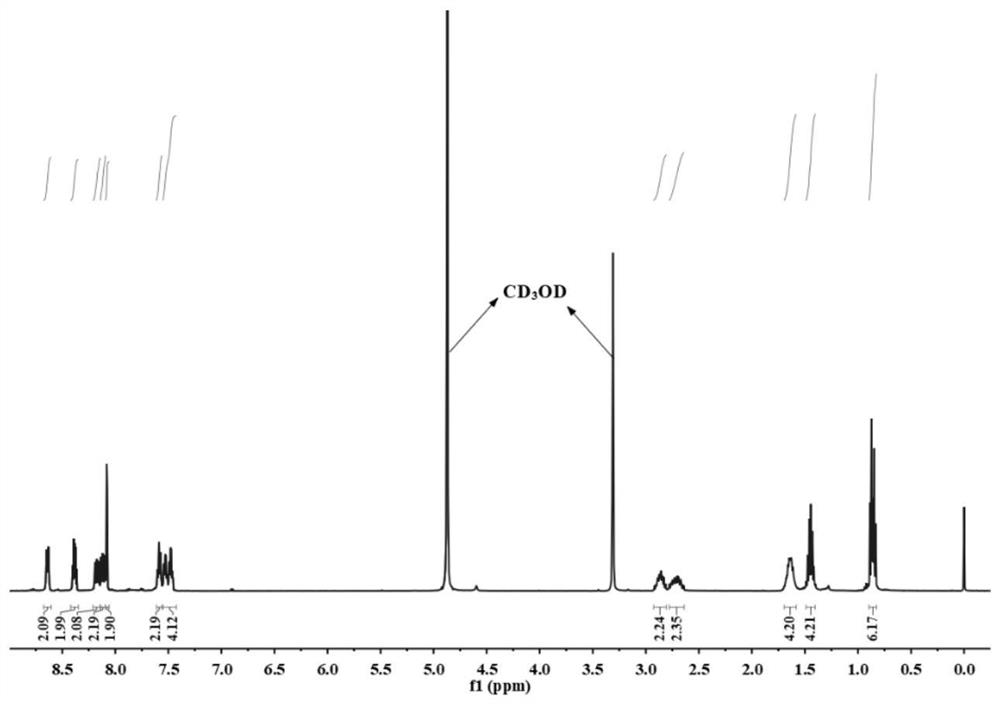

[0065] like figure 1 As shown, BuPh-PhenPO 1 H NMR spectrum, wherein each peak is attributed to: (5...

Embodiment 2

[0066] Example 2 o-phenanthroline phosphorus oxide Ph 2 - Preparation of PhenPO

[0067]

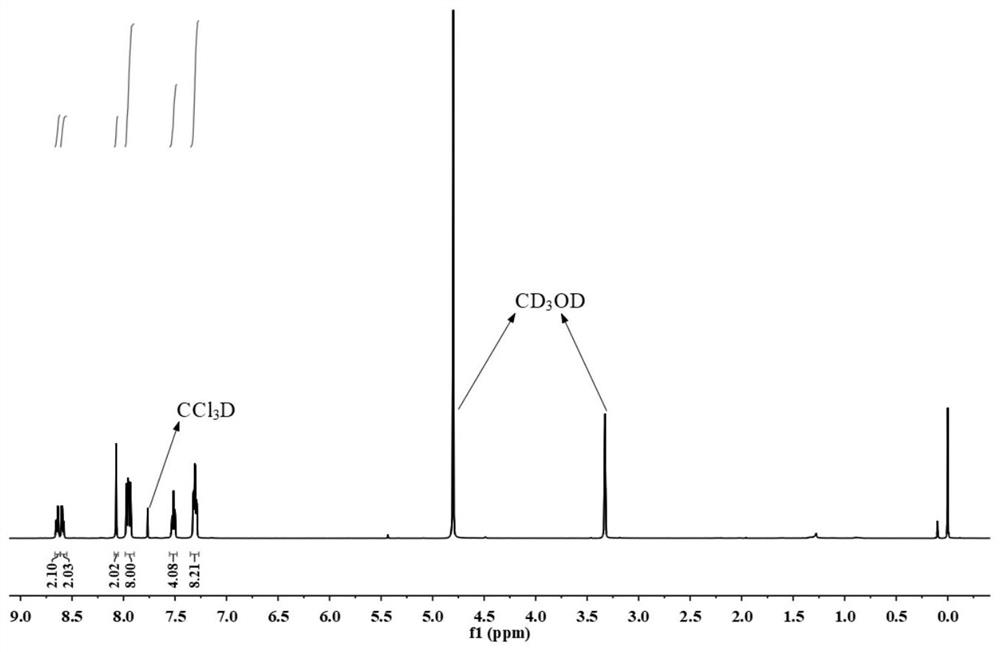

[0068] With 2,9-dichloro-1,10-phenanthroline (2,9-dichloro-1,10-phenanthroline) as the initial reactant and the intermediate product diphenylphosphine oxide in anhydrous toluene solvent, in Under high-purity argon atmosphere, fully dissolve and mix according to the mass ratio of substances (1:2.5~1:3.0), and add K under the catalysis of palladium acetate and dppf 2 CO 3 The reflux reaction was carried out for about 7 hours, and the reaction progress was tracked by TLC thin-layer chromatography until the raw materials were completely reacted. After the reaction mixture was cooled, it was washed with water to remove water-soluble impurities, dried over anhydrous sodium sulfate to remove water, and then the solvent was removed by a rotary evaporator to obtain a crude product, which was finally purified by silica gel column chromatography using dichloromethane / ethyl acetate Ester / metha...

Embodiment 3

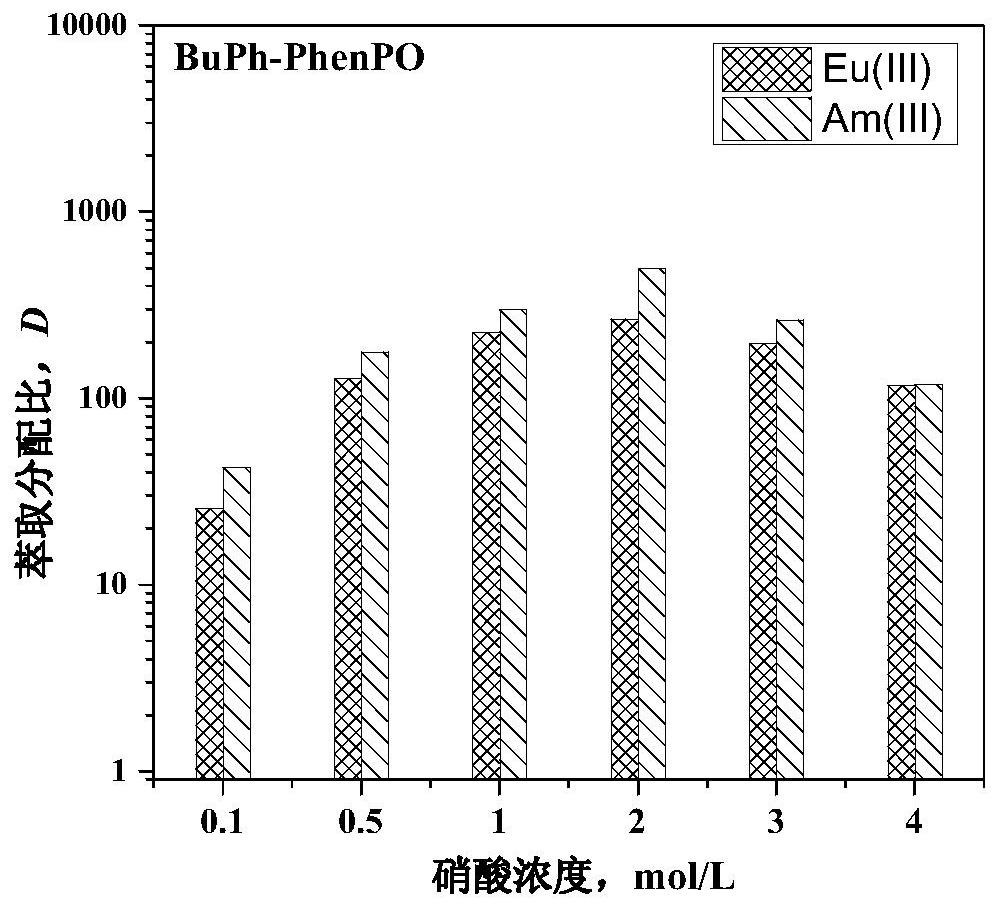

[0071] Preparation of the organic phase: Dissolve the BuPh-PhenPO prepared in Example 1 in 3-nitrobenzotrifluorotoluene solvent to prepare a 0.005 mol / liter BuPh-PhenPO solution as the organic phase of the extraction experiment;

[0072] The preparation of aqueous phase: get containing trace amount (about 10 -9 mol / L) of radioactive elements 241 Am(III) and 152, 154 The aqueous solution of Eu(III) nitric acid is diluted with deionized water and added quantitative concentrated nitric acid to prepare an aqueous solution with a series of nitric acid concentrations as the organic phase of the extraction. The concentration of nitric acid is 0.1, 0.5, 1.0, 2.0, 3.0, 4.0 mol / L;

[0073] First take 0.6mL containing 241 Am(III) and 152,154 Aqueous solutions of nitric acid with different concentrations of the Eu(III) water phase were used as the water phase in the extraction process, and were added to the ground reagent bottles containing magnetrons respectively, and 100 μL contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com