Silver-telluride-and-silver-sulfide thin film with nanorod array and preparation method of silver-telluride-and-silver-sulfide thin film

A nanorod array and film technology, applied in the field of Ag2Te-Ag2S flexible thermoelectric film and its preparation, can solve problems such as difficulty in regulating electroacoustic transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a Ag with nanorod array 2 Te-Ag 2 The preparation method of S flexible thermoelectric thin film is as follows:

[0040] (1) Use polyimide as the substrate, first pretreat the substrate, specifically: soak the substrate in detergent water in turn (detergent and water are prepared according to the mass volume ratio of 1g:50mL) , deionized water, ethanol, and acetone for ultrasonic cleaning, and after drying with high-purity nitrogen at 20°C, the substrate was subjected to Ar / H 2 Plasma cleaning under the atmosphere to obtain the pretreated substrate;

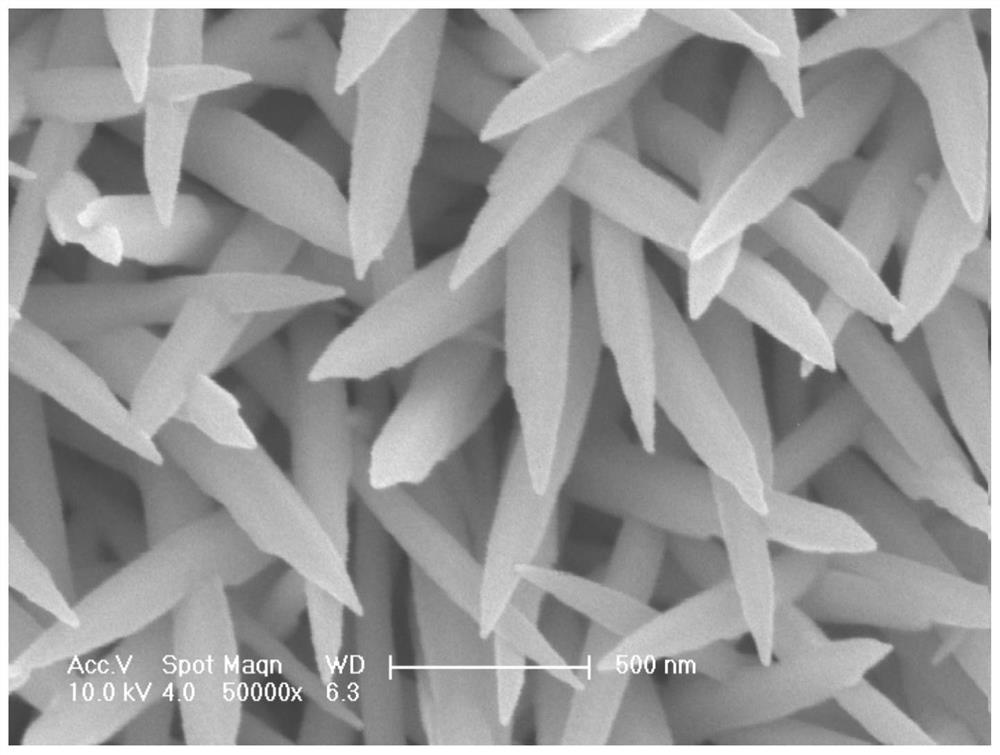

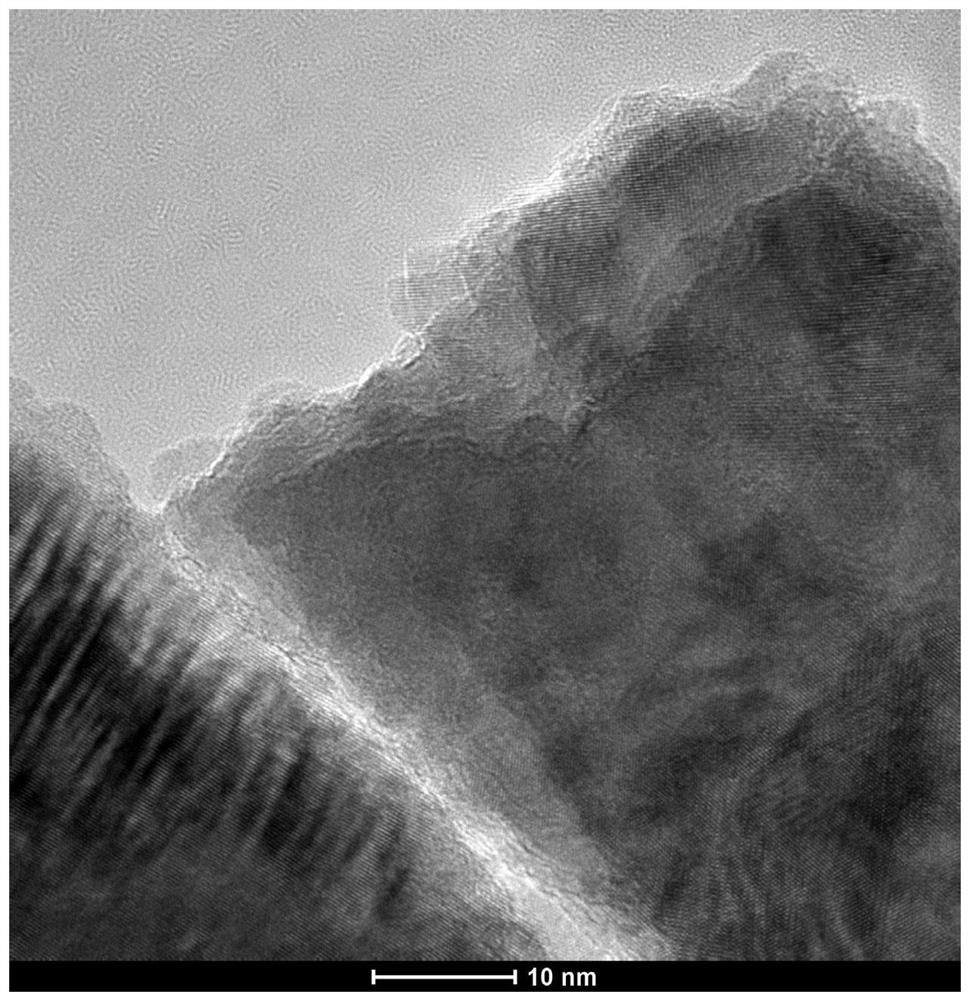

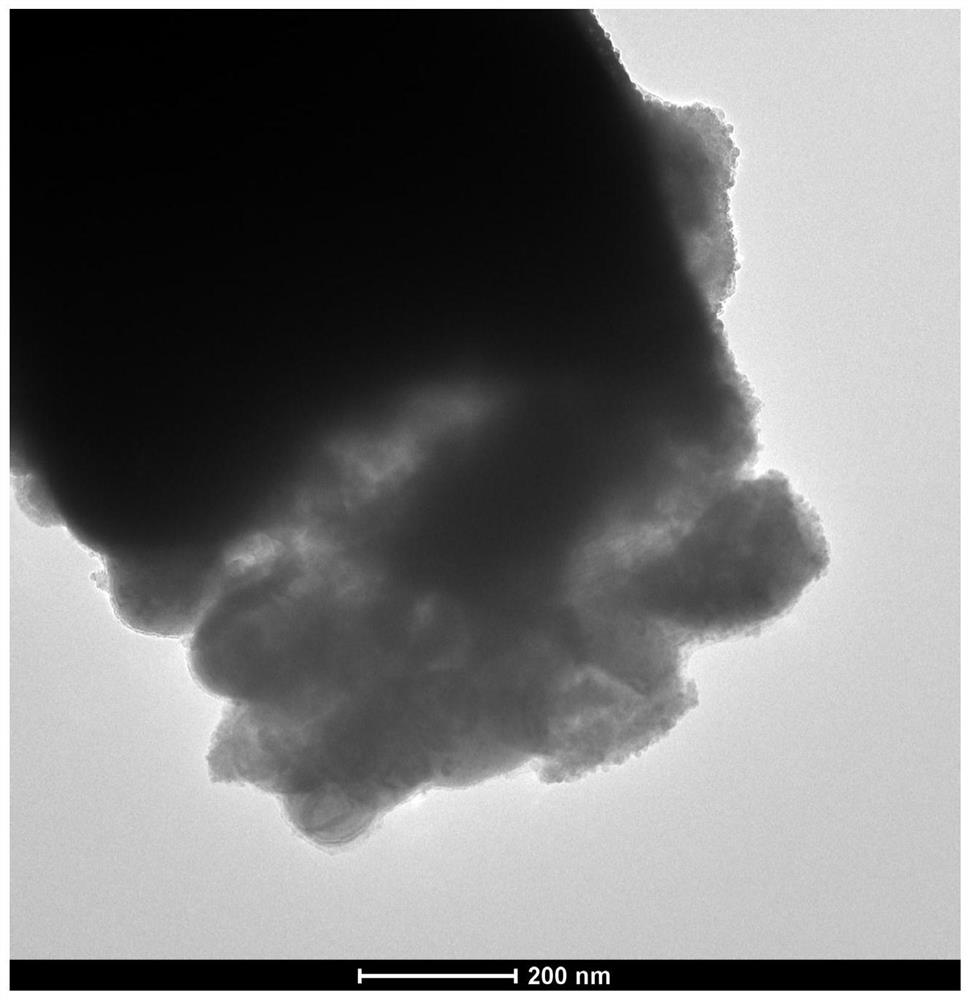

[0041] A nanorod array Te film is deposited on the pretreated substrate by radio frequency magnetron sputtering process; in the nanorod array Te film structure, the length of the nanorod is 5000nm, and the diameter of the nanorod is distributed between 50-150nm within range.

[0042] The specific operation of depositing the Te film by the radio frequency magnetron sputtering process is as follow...

Embodiment 2

[0050] This embodiment provides a Ag with nanorod array 2 Te-Ag 2 The preparation method of S flexible thermoelectric thin film is as follows:

[0051] (1) Using polyamide-imide as the substrate, first pretreat the substrate, specifically: soak the substrate in detergent water in sequence (detergent and water are prepared according to the mass volume ratio of 1g:50mL ), deionized water, ethanol, and acetone for ultrasonic cleaning, and after drying with high-purity nitrogen at 100°C, the substrate was subjected to Ar / H 2 Plasma cleaning under the atmosphere to obtain the pretreated substrate;

[0052] Using a radio frequency magnetron sputtering process, a nanorod array Te film is deposited on the pretreated substrate; in the nanorod array Te film structure, the length of the nanorod is 5000nm, and the diameter of the nanorod is 50nm;

[0053] The specific operation of depositing the Te film by the radio frequency magnetron sputtering process is as follows: (a) put the Te t...

Embodiment 3

[0061] This embodiment provides a Ag with nanorod array 2 Te-Ag 2 The preparation method of S flexible thermoelectric thin film is as follows:

[0062] (1) Using polyvinylidene fluoride as the substrate, pretreat the substrate first, specifically: soak the substrate in detergent water in sequence (detergent and water are prepared according to the mass volume ratio of 1g:50mL ), deionized water, ethanol, and acetone for ultrasonic cleaning, and after drying with high-purity nitrogen at 60°C, the substrate was subjected to Ar / H 2 Plasma cleaning under the atmosphere to obtain the pretreated substrate;

[0063] Using a radio frequency magnetron sputtering process, a nanorod array Te film is deposited on the pretreated substrate; in the nanorod array Te film structure, the length of the nanorod is 2500nm, and the diameter of the nanorod is 500nm;

[0064] The specific operation of depositing the Te film by the radio frequency magnetron sputtering process is as follows: (a) put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com