A Directly Liquid Cooled High Power Laser Gain Device Based on Fuel Injection Pump

A laser gain and high power technology, applied in the direction of laser cooling devices, lasers, laser components, etc., can solve the problems of inability to achieve high average power output, no heat management method, and inability to output high power for a long time to achieve thermal management Excellent method, guaranteed sustainability, compact device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

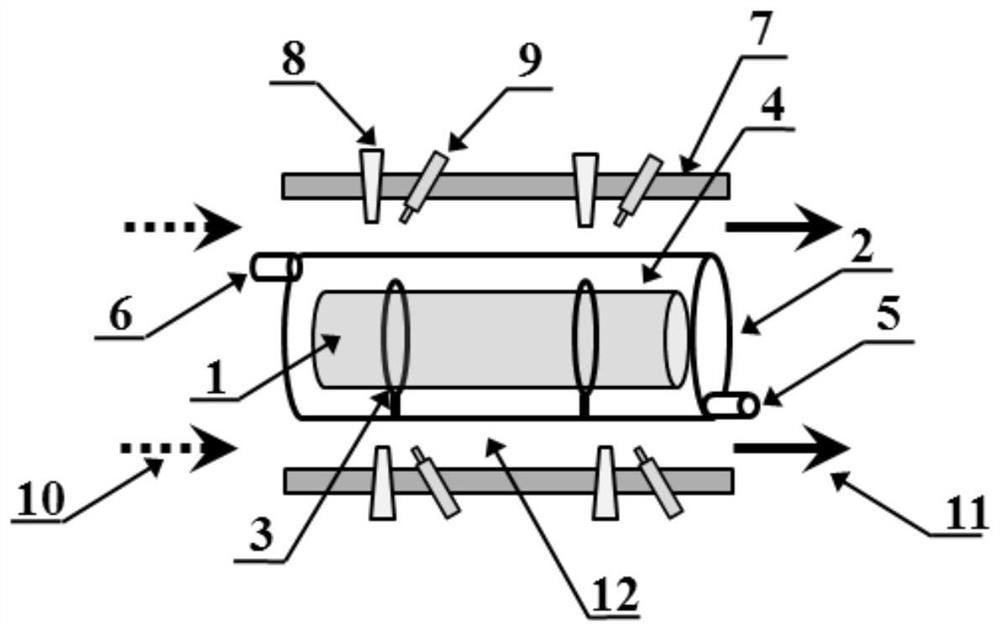

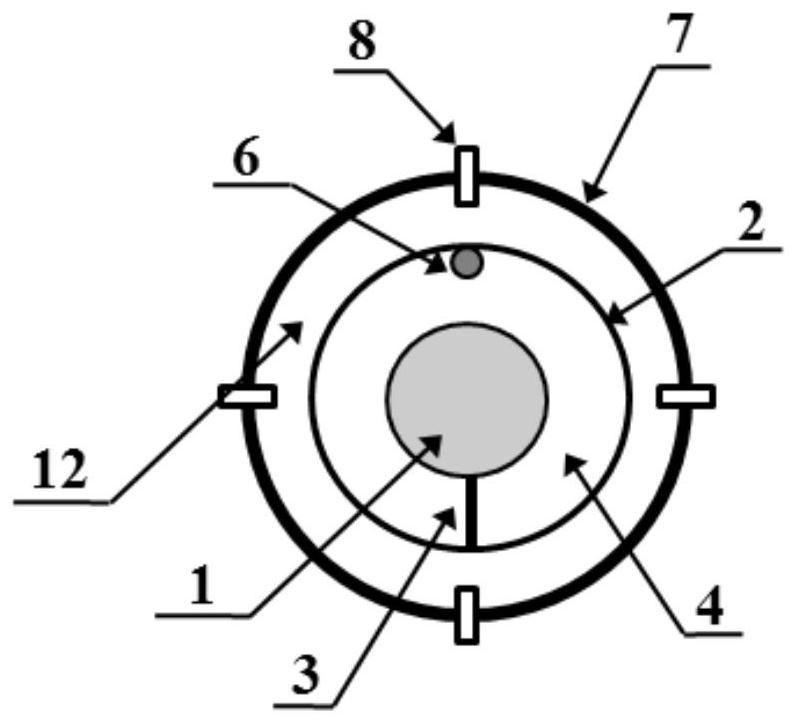

[0031] Such as Figure 1-Figure 2 as shown, figure 1 It is a direct liquid-cooled high-power laser gain device pumped by fuel injection. The gain device structure includes: gain medium (1), device inner frame (2), gain medium fixing bracket (3), laser cooling liquid (4), cooling liquid inlet (5), cooling liquid outlet (6), device outer Frame (7), fuel nozzle (8), ignition plug (9), high-speed airflow inlet (10), exhaust gas outlet (11), combustion chamber (12). The laser gain medium (1) is fixedly installed in the inner frame (2) of the device through the gain medium fixing bracket (3), and the gain source of the laser gain medium (1) is the strong light generated by the combustion of liquid or gaseous fuel. A device outer frame (7) is also provided outside the device inner frame (2), and a combustion chamber (12) for fuel combustion is formed between the device inner frame (2) and the device outer frame (7), as figure 2 A cross-sectional view of the laser gain device is s...

Embodiment 2

[0041] This embodiment provides an operation method of a direct liquid-cooled high-power solid-state laser gain device for a fuel injection pump. After starting to work, select and adjust the injection flow value and pressure of one or several fuel nozzles (8), then open the high-speed air inlet (10), fuel nozzle (8), and ignition plug (9) in sequence, and the fuel passes through The fuel nozzle (8) is injected into the combustion chamber (12), and at the same time, the high-speed air or high-speed oxygen flow reaches the combustion chamber (12) through the high-speed airflow inlet (10), and the injected fuel is fully mixed with the high-speed airflow Finally, after being ignited by the ignition plug (9), it continues to burn in the combustion chamber (12), and the intense light emitted by the high-temperature combustion causes the gain medium (1) to achieve upper-level particle population inversion and thus realize high-power laser output.

Embodiment 3

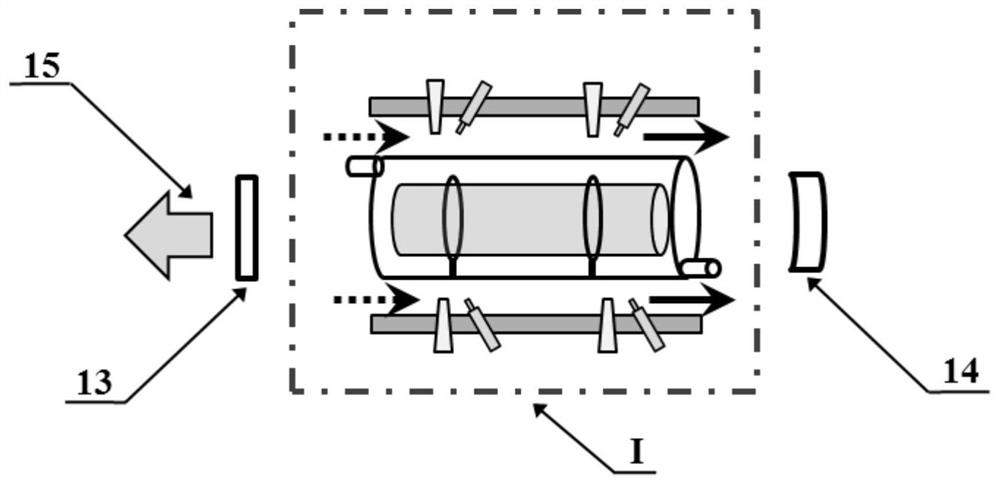

[0043] This embodiment also provides a high-power cavity-stabilized laser based on the gain device of any of the preceding embodiments, such as image 3 shown. The high-power cavity-stabilized laser system includes a gain device (I), and both sides of the gain device (I) are respectively provided with a laser total reflection mirror (14) and a coupling output mirror (13), thereby forming a laser resonant cavity. The gain device (I) is a direct liquid-cooled high-power solid-state laser gain device of the fuel injection pump in any of the foregoing embodiments. After the high-power cavity-stabilized laser starts to work, the high-energy excitation in the gain device (I) The radiation is continuously amplified by the intracavity oscillation of the laser resonator, and then coupled by the output coupling mirror (13) to form an output laser (15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com