Preparation method of N-alkyl phthalimide

A technology of alkyl phthalimide and phthalic anhydride, which is applied in the chemical industry, can solve problems such as residue, product loss, and yield reduction, and achieve a process with loose reaction conditions, easy realization, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

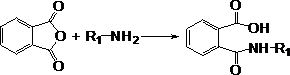

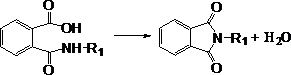

Method used

Image

Examples

Embodiment 1

[0038] Put phthalic anhydride into the flask, blow nitrogen, and slowly add dropwise an aqueous solution of isopropylamine with a molar concentration of 96%; wherein, the molar ratio of phthalic anhydride to isopropylamine is 1:3, increasing Temperature, control the temperature at 50°C, react for 2 hours, all phthalic anhydride dissolves to form a transparent solution; continue to raise the temperature to 140°C, distill out the water and excess isopropylamine in the system until there is no more water vapor in the system After the reaction is completed, the material is discharged to obtain N-isopropylphthalimide, which is a white crystal with a melting point of 81.9°C, a yield of 97%, and a purity of 99.5%.

[0039] During the distillation process, the tail gas was condensed and collected to obtain an aqueous solution of isopropylamine with a concentration of 79.6%.

Embodiment 2

[0041] Put phthalic anhydride into the flask, pass nitrogen gas, and slowly drop an aqueous solution of n-butylamine with a molar concentration of 98%; wherein, the molar ratio of phthalic anhydride to n-butylamine is 1:2; Raise the temperature, control the temperature at 90°C, react for 48 minutes, all the phthalic anhydride dissolves and form a transparent solution; continue to raise the temperature to 180°C, distill out the water and excess n-butylamine in the system until there is no more Water was evaporated, the reaction was completed, and the material was discharged to obtain N-n-butylphthalimide as white crystals with a melting point of 29.8°C, a yield of 96.2%, and a purity of 99.3%.

[0042] During the distillation process, the tail gas was condensed and collected to obtain an aqueous solution of n-butylamine with a concentration of 74.1%.

Embodiment 3

[0044] Put phthalic anhydride into the flask, pass nitrogen gas, and slowly add dropwise an aqueous solution of n-propylamine with a molar concentration of 98%; wherein, the molar ratio of phthalic anhydride to n-propylamine is 1:1.3; Temperature, control the temperature at 80°C, react for 30 minutes, all phthalic anhydride dissolves to form a transparent solution; after the dissolution is completed, transfer the material to a rotary evaporator for vacuum distillation, raise the temperature to 120°C, and distill out the system of water and excess n-propylamine, until no more water is distilled out in the system, the reaction is completed, and the material is discharged to obtain N-n-propylphthalimide, which is a white crystal with a melting point of 70.8°C and a yield of 98 %, 99.6% purity.

[0045] During the distillation process, the tail gas was condensed and collected to obtain an aqueous solution of n-propylamine with a concentration of 42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com