A method for nano-deep surface activation of PTFE-based membranes

A surface activation and deep technology, applied in the direction of film/sheet adhesive, pressure-sensitive film/sheet, non-polymer organic compound adhesive, etc. The advantages of low surface tension performance are reduced, and it is unable to resist the adhesion of ice crystals, etc., to achieve the effects of UV aging resistance and long aging resistance, enhanced adhesive strength and adhesive peeling force, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

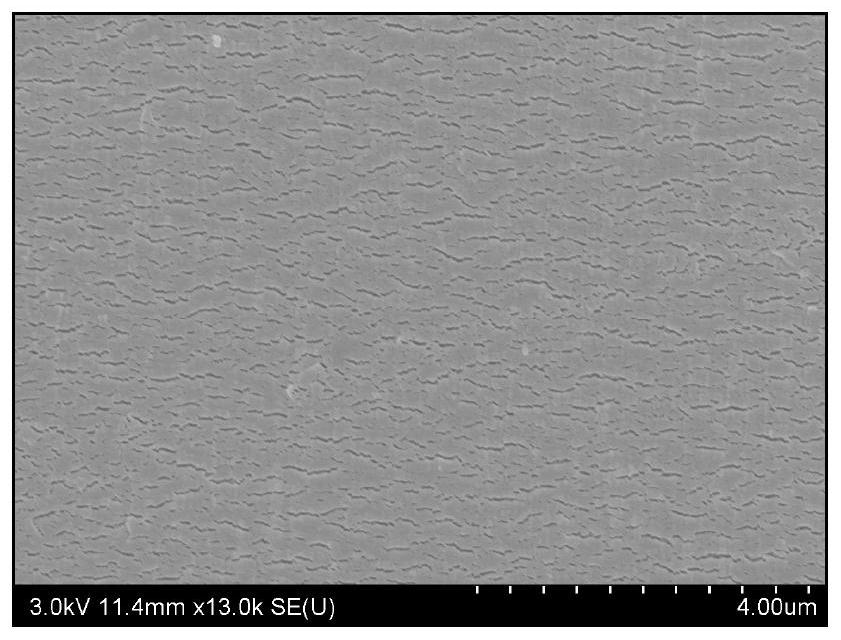

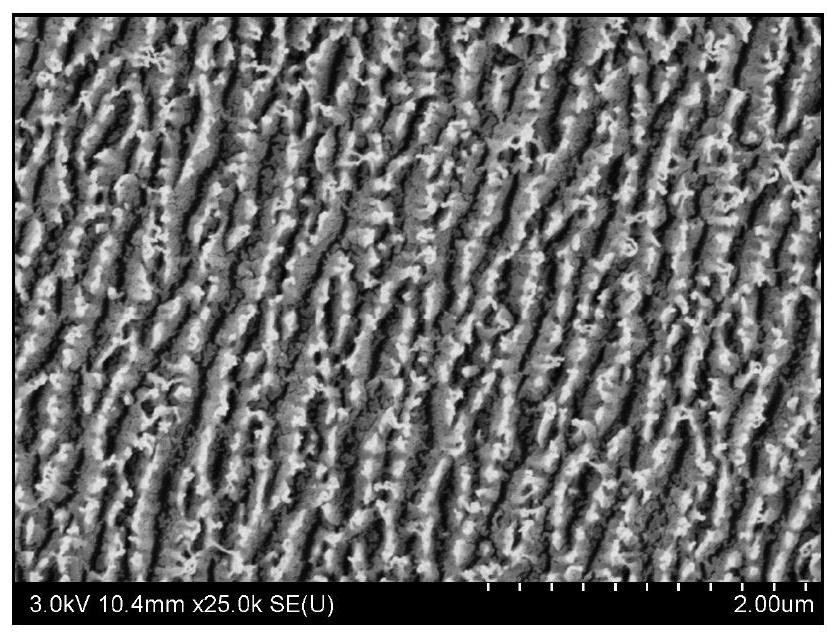

[0031] This embodiment provides a method for nano-deep surface activation based on PTFE membranes. The functional surface of PTFE nano-functional composite membranes with nano-scale and micron-scale concave-convex geometric shapes and ultra-microstructure morphology is covered with PE membranes. Finally, one side of the film to which the adhesive glue is applied is subjected to surface activation treatment at a speed of 3 m / min in a nitrogen-hydrogen mixed medium atmosphere lower than 40°C in a vacuum environment, so that the glued surface of the film has a nanometer depth. Activation of the structural layer; the high-toughness cold adhesive tape is migrated and compounded on the membrane surface of the PTFE-based nano-functional composite membrane with the activated structural layer through a mechanical sizing device, so that the characteristic groups of the glue and the activated structural layer of the membrane are chemically bonded Cooperate to form a glue-film complex.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com