Polyvinyl alcohol-bacterial cellulose sandwich structure type alkaline anion exchange membrane as well as preparation and application thereof

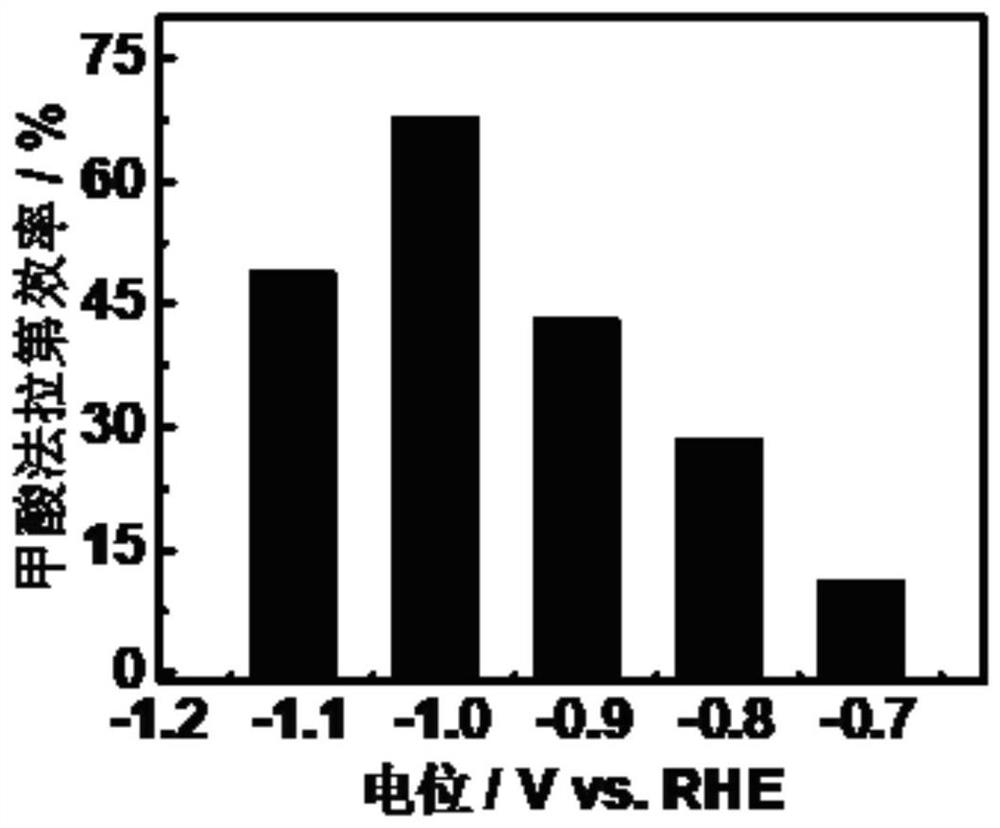

A technology of bacterial cellulose membrane and bacterial cellulose, applied in the field of polyvinyl alcohol/bacterial cellulose sandwich structure alkaline anion exchange composite membrane, can solve the problems of high cost and complicated preparation of alkaline anion exchange membrane, and achieve low cost , good CO2 electrochemical reduction performance and zinc-air battery charge and discharge performance, and the green effect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

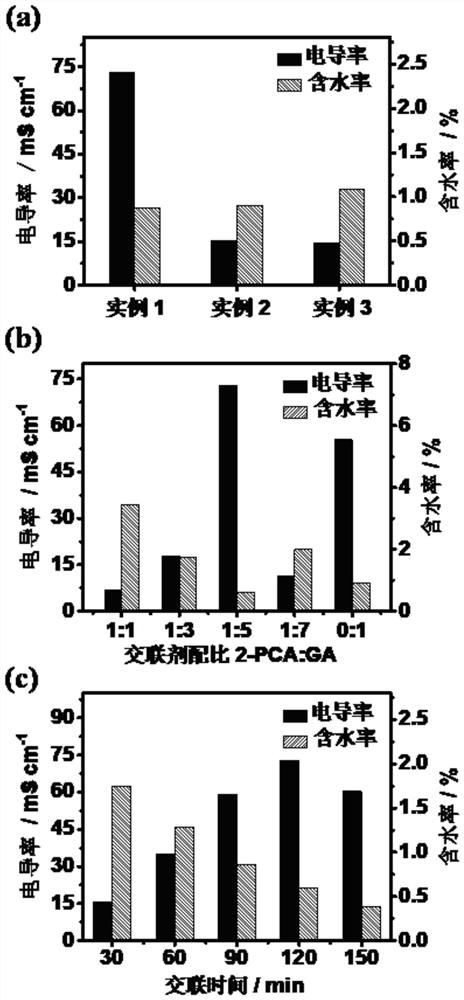

Embodiment 1

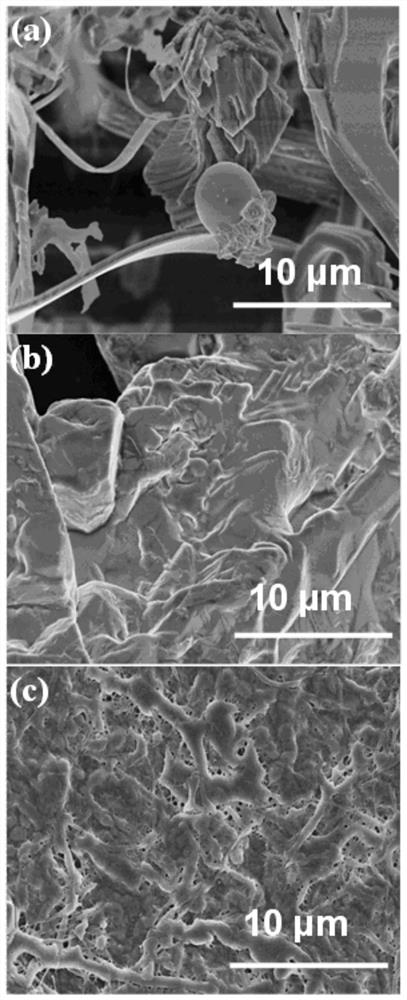

[0032] A kind of preparation method of basic anion exchange composite membrane of PVA-BC sandwich structure formula:

[0033] Step 1: Dissolve 5g of glucose, 0.5g of tryptone and 0.3g of yeast extract powder in 100mL of deionized water and stir to adjust the pH to 5.0-6.0 and evenly seal and distribute them in 5 petri dishes, then heat at 115°C Autoclave for 30 minutes, inoculate 1 mL of bacterial solution (number DHU-ATCC-1) into each petri dish (in the sterilization station), seal it again and place it in a constant temperature incubator at 30°C for constant temperature cultivation until the medium is completely absorbed , put it into 1wt.% NaOH solution for 2 days for purification to remove attached bacteria and excess nutrient solution to obtain BC film;

[0034]Step 2: Dissolve hydroxyl-containing PVA with a molecular weight LW of 89,000-98,000 in deionized water, stir at 80-95°C until a uniform and transparent solution is obtained, and dissolve the water-soluble polymer ...

Embodiment 2

[0039] A kind of preparation method of basic anion exchange composite membrane of PVA-BC sandwich structure formula:

[0040] Step 1: Dissolve 5g of glucose, 0.5g of tryptone and 0.3g of yeast extract powder in 100mL of deionized water and stir to adjust the pH to 5.0-6.0 and evenly seal and distribute them in 5 petri dishes, then heat at 115°C Autoclave for 30 minutes, inoculate 1 mL of bacterial solution (number DHU-ATCC-1) into each petri dish (in the sterilization station), seal it again and place it in a constant temperature incubator at 30°C for constant temperature cultivation until the medium is completely absorbed , put it into 1wt.% NaOH solution for 2 days for purification to remove attached bacteria and excess nutrient solution to obtain BC film;

[0041] Step 2: Dissolve hydroxyl-containing PVA with a molecular weight of 146,000-186,000 in deionized water, and stir at 80-95°C until a uniform and transparent solution is obtained, and the water-soluble polymer conta...

Embodiment 3

[0046] A kind of preparation method of basic anion exchange composite membrane of PVA-BC sandwich structure formula:

[0047] Step 1: Dissolve 5g of glucose, 0.5g of tryptone and 0.3g of yeast extract powder in 100mL of deionized water and stir to adjust the pH to 5.0-6.0 and evenly seal and distribute them in 5 petri dishes, then heat at 115°C Autoclave for 30 minutes, inoculate 1 mL of bacterial solution (number DHU-ATCC-1) into each petri dish (in the sterilization station), seal it again and place it in a constant temperature incubator at 30°C for constant temperature cultivation until the medium is completely absorbed , put it into 1wt.% NaOH solution for 2 days for purification to remove attached bacteria and excess nutrient solution to obtain BC film;

[0048] Step 2: Dissolve hydroxyl-containing PVA with a molecular weight HW of 205,000 in deionized water, stir at 80-95°C until a uniform and transparent solution is obtained, and chlorinate the water-soluble polymer con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap