A kind of high-strength wear-resistant brass alloy and its preparation method

A brass alloy, high-strength technology, applied in the field of metal alloy materials, can solve the problems of high corrosion rate, affecting alloy processing performance, mechanical properties, corrosion resistance and poor high temperature hot cracking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This embodiment provides a high-strength wear-resistant brass alloy, including:

[0075] Cu 58.5%;

[0076] Mn 2.7%;

[0077] CO 0.8%;

[0078] Si 3.2%;

[0079] Al 3.6%;

[0080] Ni 2.8%;

[0081] Fe 1.5%;

[0082] Pb 0.1%;

[0083] Zn and unavoidable impurities.

[0084] in,

[0085] f 1 =P Mn / P Co =3.375;

[0086] f 2 =4×P Si / 28+3×P Al / 27=23.6%;

[0087] f 3 =P Ni ×P Fe =0.42‰.

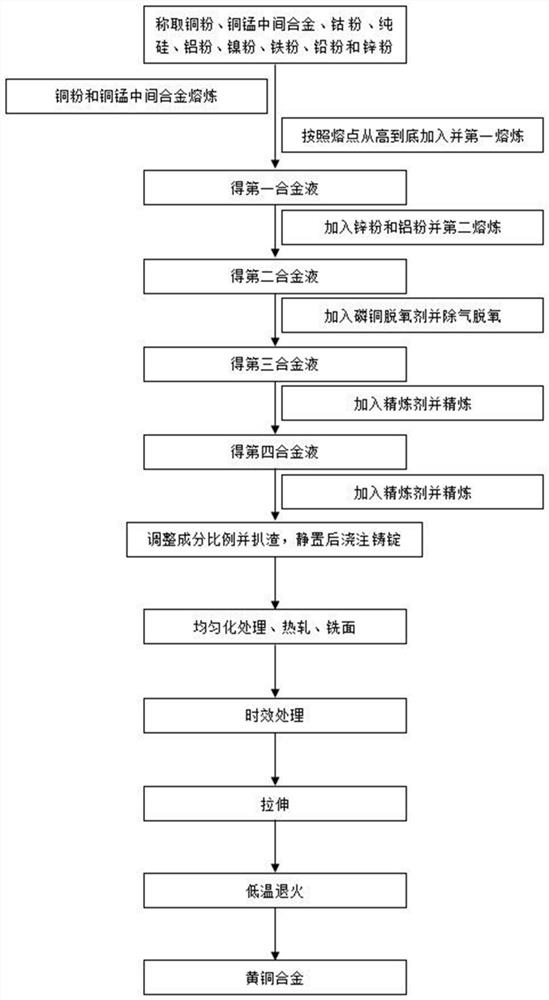

[0088]Weigh copper powder, copper-manganese master alloy, cobalt powder, pure silicon, aluminum powder, nickel powder, iron powder, lead powder and zinc powder according to the proportion; smelt copper powder and copper-manganese master alloy, after heating up, follow the melting point from Add various components from high to low and perform the first smelting to obtain the first alloy liquid; add zinc powder and aluminum powder to the first alloy liquid for second smelting to obtain the second alloy liquid; add phosphor copper deoxidizer to the second alloy liquid for...

Embodiment 2

[0106] Example 2 provides a series of brass alloys respectively, which are marked as 2# to 12#;

[0107] Table 1. Proportion content of brass alloy

[0108]

[0109] The series of brass alloys described in Examples 2# to 12# are all prepared by the same method as in Example 1, that is, the aging treatment temperature is 706°C, and the time is 120min; the stretching temperature is 680°C, and the stretching temperature The speed is 1 mm / min; the low temperature annealing temperature is 283°C.

Embodiment 3

[0111] Embodiment 3 provides a kind of high-strength wear-resistant brass alloy, denoted as 13#:

[0112] Cu 58.5%;

[0113] Mn 2.7%;

[0114] CO 0.8%;

[0115] Si 3.2%;

[0116] Al 3.6%;

[0117] Ni 2.8%;

[0118] Fe 1.5%;

[0119] Pb 0.1%;

[0120] Zn and unavoidable impurities.

[0121] in,

[0122] f 1 =P Mn / P Co =3.375;

[0123] f 2 =4×P Si / 28+3×P Al / 27=23.6%;

[0124] f 3 =P Ni ×P Fe =0.42‰.

[0125] Weigh copper powder, copper-manganese master alloy, cobalt powder, pure silicon, aluminum powder, nickel powder, iron powder, lead powder and zinc powder according to the proportion; smelt copper powder and copper-manganese master alloy, after heating up, follow the melting point from Add each component from high to low, perform the first melting at 1225°C for 20 minutes to obtain the first alloy liquid; add zinc powder and aluminum powder to the first alloy liquid, and perform the second melting at 1150°C for 15 minutes to obtain the second alloy liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com