A kind of liquid phase coating modification prepares the method for negative electrode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of capacity decay, consumption, cycle performance decline, etc., to prevent dissociation, high cycle efficiency, and improve cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing lithium-ion battery negative electrode materials by liquid-phase coating modification, comprising the following steps:

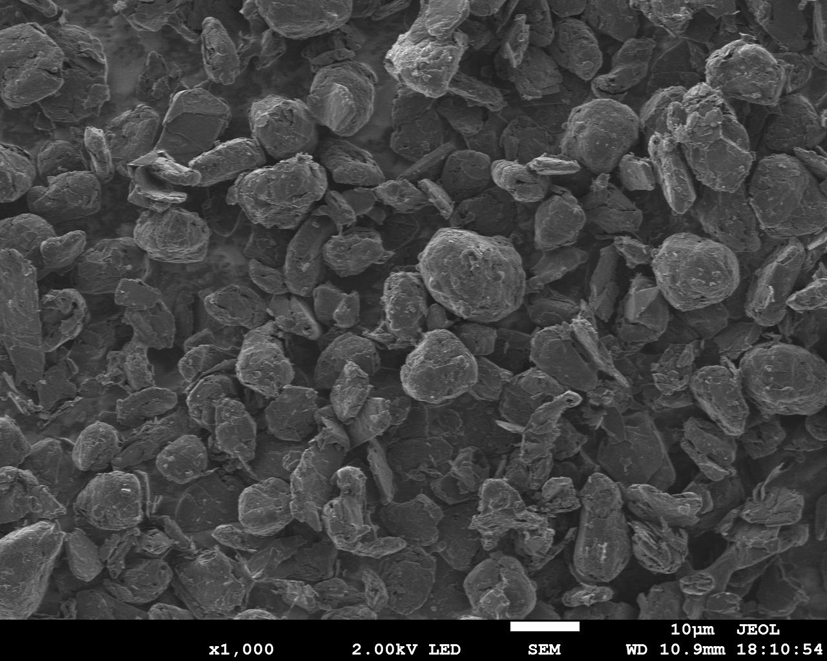

[0026] S1. Mechanically pulverize the natural flake graphite, and then classify the pulverized fine powder according to the particle size to obtain a natural flake graphite powder with a particle size of 5-20 μm and a purity of 99.5%;

[0027] S2. Weigh 3g of medium-temperature coal tar pitch and add it to 97g of toluene, stir at high speed (2000rad / min) for 20min to dissolve the pitch more fully, and prepare a medium-temperature coal tar pitch solution with a mass fraction of 3%; then, pour the prepared pitch solution Put it into a static settling tank and let it stand for 6 hours to make the insoluble matter in the solution fully settle and then take the supernatant to prepare the coating solution;

[0028] S3, add 10g of natural flake graphite powder prepared in step S1 into the impregnation kettle, vacuumize the impregnation...

Embodiment 2

[0033] A method for preparing lithium-ion battery negative electrode materials by liquid-phase coating modification, comprising the following steps:

[0034] S1. Mechanically pulverize the natural flake graphite, and then classify the pulverized fine powder according to the particle size to obtain a natural flake graphite powder with a particle size of 10-25 μm and a purity of 99.6%;

[0035] S2. Weigh 6g of high-temperature coal tar pitch and add it to 94g of pyridine, stir at high speed (1000rad / min) for 30min to dissolve the pitch more fully, and obtain a high-temperature coal tar pitch solution with a mass fraction of 6%; then, pour the prepared pitch solution Put it in a static settling tank and let it stand for 12 hours, after the insoluble matter in the solution is fully settled, take the supernatant liquid to prepare the coating liquid;

[0036] S3, add 10g of natural flake graphite powder prepared in step S1 into the impregnation kettle, vacuumize the impregnation ket...

Embodiment 3

[0041] A method for preparing lithium-ion battery negative electrode materials by liquid-phase coating modification, comprising the following steps:

[0042] S1. Mechanically pulverize the natural aphanitic graphite, and then classify the pulverized fine powder according to the particle size to obtain a natural aphanitic graphite powder with a particle size of 8-30 μm and a purity of 99.7%;

[0043] S2. Weigh 10g of high-temperature coal tar pitch and add it to 90g of quinoline, stir at high speed (1500rad / min) for 50min to dissolve the pitch more fully, and obtain a high-temperature coal tar pitch solution with a mass fraction of 10%; then, the prepared pitch solution Pour it into a static settling tank and let it stand for 24 hours to allow the insoluble matter in the solution to fully settle and then take the supernatant to obtain a coating solution;

[0044] S3. Add 10 g of natural aphanitic graphite powder prepared in step S1 into the impregnation kettle. After the impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com