Ceramic microsphere, diaphragm containing ceramic microsphere and lithium ion battery containing diaphragm

A technology of ceramic microspheres and microspheres, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of limited application, small voltage sensitive range, high cost, etc., and achieve the effect of improving safety performance and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] [Preparation method of ceramic microspheres]

[0042] As mentioned above, the present invention also provides a method for preparing the above-mentioned ceramic microspheres, the method comprising the following steps:

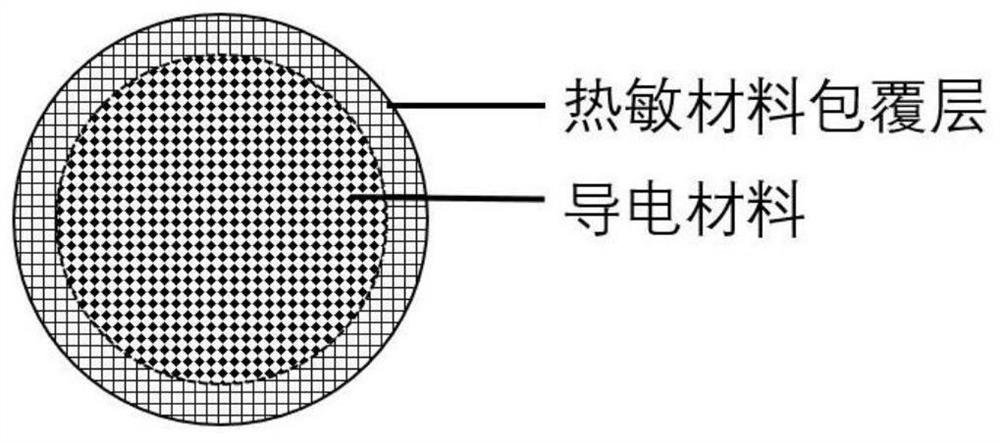

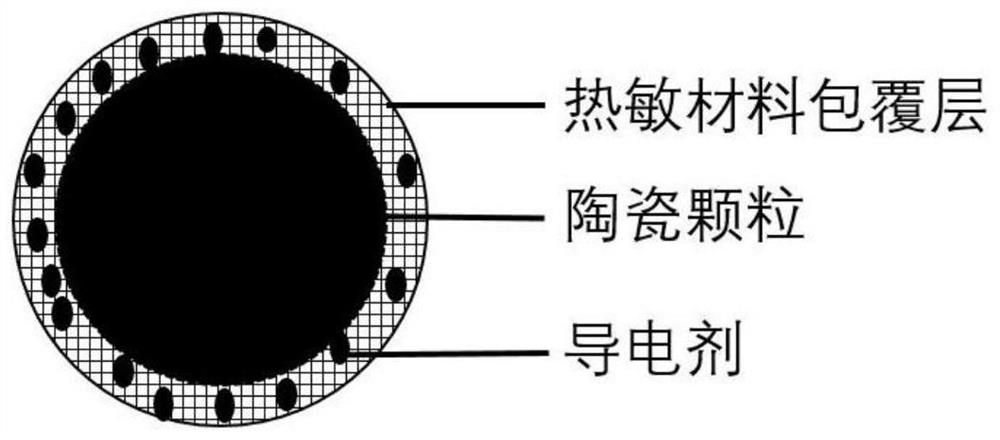

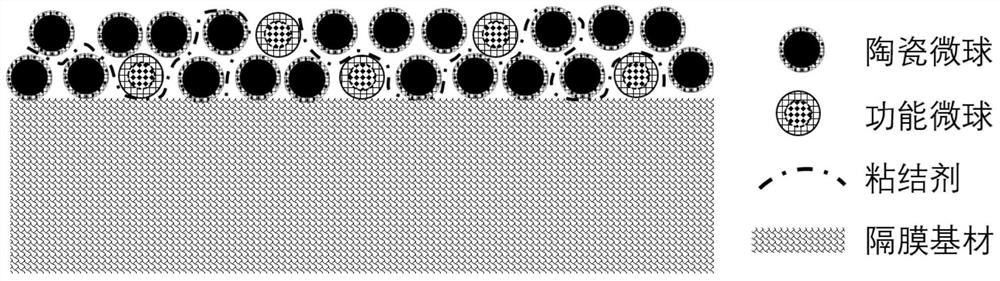

[0043] Using a liquid-phase coating method or a solid-phase coating method, coating a shell-forming material including a thermosensitive polymer and a conductive agent on the surface of a core-forming material including a ceramic material to prepare the ceramic microspheres; Wherein, the ceramic microsphere has a core-shell structure, that is, includes a shell layer and a core, the material forming the shell layer includes a thermosensitive polymer and a conductive agent, and the material forming the core core includes a ceramic material.

[0044] Exemplarily, in the case of using a liquid-phase coating method, the liquid-phase coating method includes the following steps:

[0045] The material forming the shell layer is dissolved in a solvent by stirrin...

Embodiment 1

[0103] 0.5g polyethylene terephthalate is dissolved in cresol by stirring mode, forms mixed solution, adds 50g to dope 20wt.% perfluoromethanesulfonic acid (CF 3 SO 3 H) Pyrolyzed polyvinyl alcohol, after stirring and mixing uniformly, the solvent in the mixture is removed by spray drying technology to obtain microspheres coated with conductive materials by thermosensitive polymers.

[0104] In the prepared conductive microspheres, the shell layer is polyethylene terephthalate, and the core is doped with 20wt.% perfluoromethanesulfonic acid (CF 3 SO 3 H) pyrolyzed polyvinyl alcohol; the mass ratio of the shell to the core is 0.5:50, the thickness of the shell is 1 nm, and the average particle size of the microspheres is about 0.01 μm.

[0105] Dissolve 0.2g polyethylene terephthalate and conductive carbon black (the mass ratio of thermosensitive polymer: conductive carbon black=100:1) in cresol by stirring to form a mixed solution, add 50g Boehm After stirring and mixing un...

Embodiment 2

[0110] 200g polystyrene was dissolved in benzene by stirring to form a mixed solution, and 60g doped with 30wt% tungsten hexafluoride (WF 6 ) of polyacetylene, after stirring and mixing evenly, the solvent in the mixture is removed by spray drying technology to obtain microspheres of thermosensitive polymer-coated conductive materials.

[0111] In the prepared conductive microspheres, the shell is polystyrene, and the core is doped with 30wt% tungsten hexafluoride (WF 6 ) of polyacetylene; the mass ratio of the shell to the core is 200:60, the thickness of the shell is 400nm, and the average particle diameter of the microspheres is about 10 μm.

[0112] 0.32g polystyrene and conductive agent Ketjen black (wherein thermosensitive polymer: the mass ratio of conductive agent Ketjen black=1000:1) are dissolved in benzene by stirring mode, form mixed solution, add 80g zirconium dioxide, After stirring and mixing evenly, the solvent in the mixture is removed by spray drying technol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com