Micro/nano hierarchical porous microspheres as well as preparation method and application thereof

A graded porous and nano-technology, applied in the fields of application, pharmaceutical formulation, pharmaceutical science, etc., can solve the problem of difficulty in improving the effect, and achieve the effect of reducing the possibility, not easy to slip off, and shortening the time of wound hemostasis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

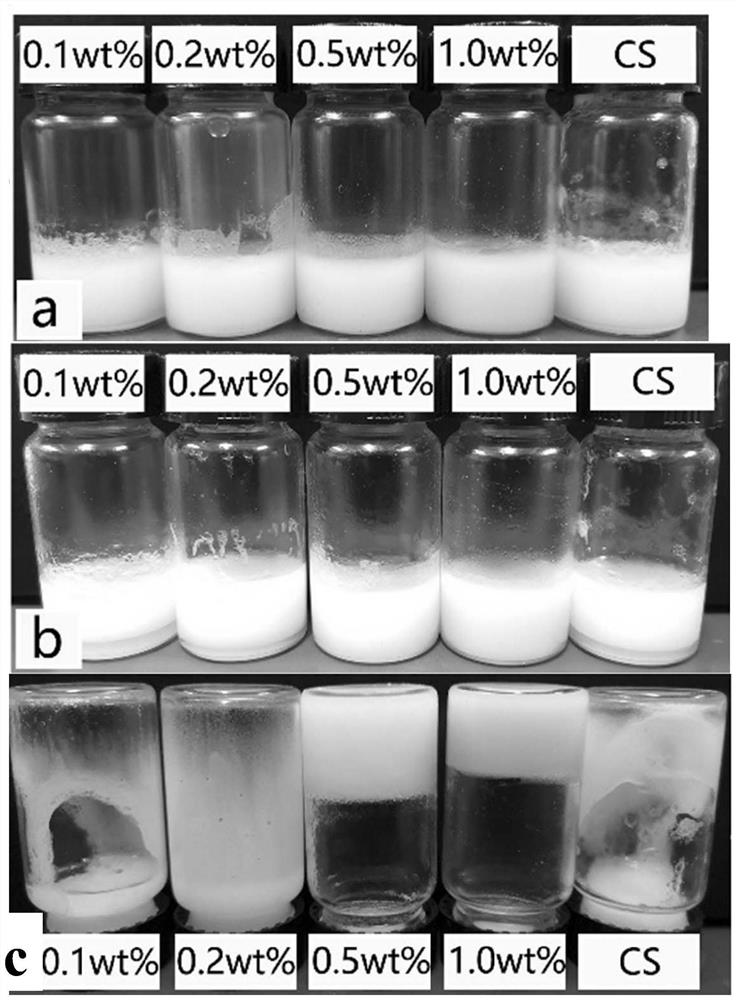

[0052] The preparation of the mixed solution (CS / Ch) of embodiment 1 chitin nanofiber and chitosan

[0053] Add a certain quality of chitin into ionized water to prepare chitin solutions with a concentration of 0wt%, 0.1wt%, 0.2wt%, 0.5wt%, and 1.0wt%, and add 1% acetic acid solution by volume to adjust the pH value to 3 ~4, Stir for 24 hours, grind with a grinder, the grinding pressure is 200MPa, the grinding times is 50times, and then dispersed by a high-speed homogenizer, the speed is 10000rpm, the homogenization time is 1h, and a stable and uniform suspension of chitin nanofibers is obtained . Take a certain amount of chitosan powder and add it into an acetic acid solution with a volume ratio of 1%. The concentration of the chitosan solution is 2.0 wt%, and mechanically stir until the chitosan is completely dissolved. The same volume of chitin nanofiber suspension and chitosan solution were taken, mixed, and homogenized by a high-speed homogenizer at a speed of 8000 rpm a...

Embodiment 2

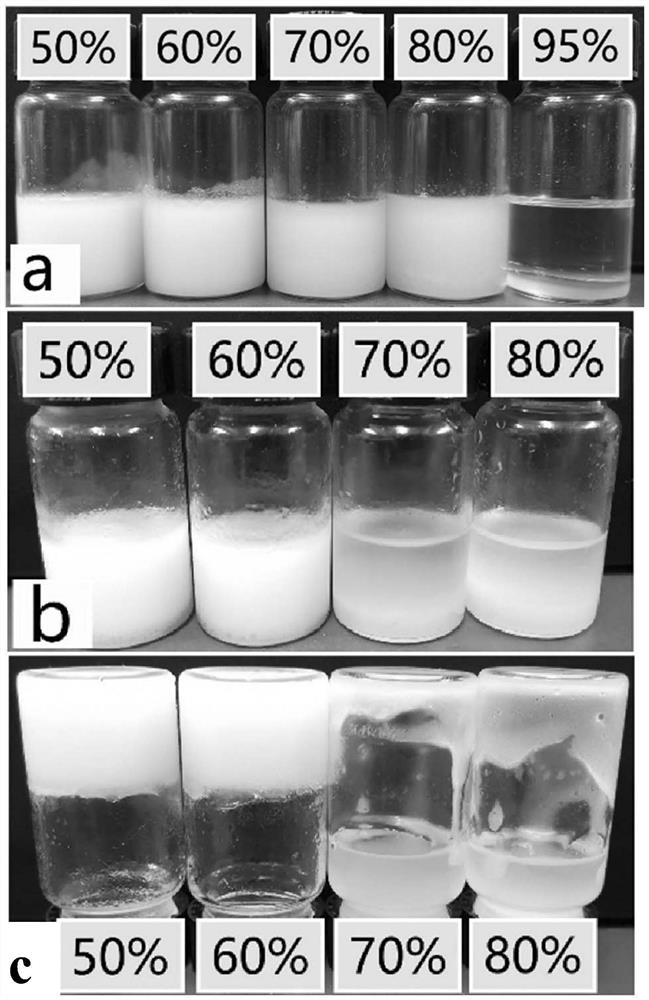

[0054] The preparation of the mixed solution of embodiment 2 chitin nanofibers and chitosan

[0055] Add a certain quality of chitin into ionized water to prepare a chitin solution with a concentration of 0.2wt%, add 1% acetic acid solution by volume to adjust the pH value to 3-4, stir for 24 hours, grind with a grinder, and the grinding pressure is 300MPa , the number of times of grinding is 30times, and then dispersed by a high-speed homogenizer with a rotating speed of 9000rpm and a homogenization time of 1.5h to obtain a stable and uniform suspension of chitin nanofibers (fiber length is 100nm). Take a certain amount of chitosan powder and add it into an acetic acid solution with a volume ratio of 2%, the concentration of the chitosan solution is 3.0 wt%, and mechanically stir until the chitosan is completely dissolved. The same volume of chitin nanofiber suspension and chitosan solution were taken, mixed, and homogenized by a high-speed homogenizer at a speed of 10,000 rp...

Embodiment 3

[0056] The preparation of the mixed solution of embodiment 3 chitin nanofibers and chitosan

[0057] Add a certain quality of chitin into ionized water to prepare a chitin solution with a concentration of 0.5wt%, add 1% acetic acid solution by volume to adjust the pH value to 3-4, stir for 24 hours, grind with a grinder, and the grinding pressure is 400MPa , the number of times of grinding is 40times, and then dispersed by a high-speed homogenizer with a rotating speed of 12000rpm and a homogenization time of 2h to obtain a stable and uniform suspension of chitin nanofibers (fiber length is 50nm). Take a certain amount of chitosan powder and add it into an acetic acid solution with a volume ratio of 2%, the concentration of the chitosan solution is 3.0 wt%, and mechanically stir until the chitosan is completely dissolved. The same volume of chitin nanofiber suspension and chitosan solution were taken, mixed, and homogenized by a high-speed homogenizer with a homogenization spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com