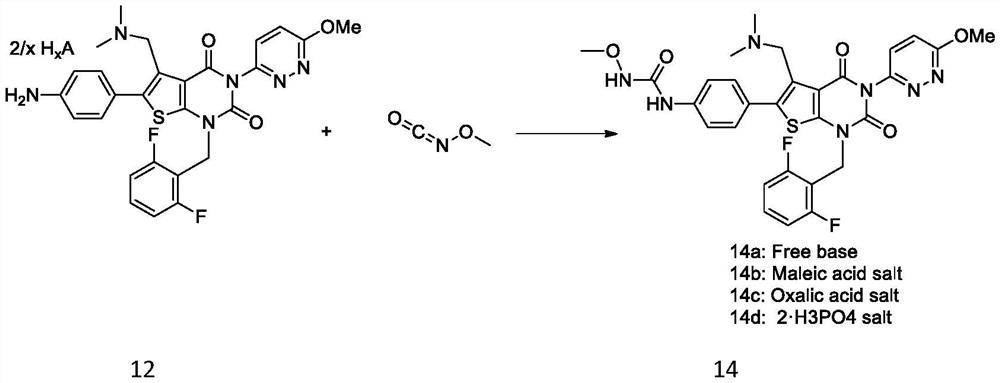

Synthesis method of relugolix or salt thereof

A synthetic method and compound technology, applied in the field of medicine and chemical industry, can solve the problems of difficult condensation reaction, high cost of enlarged production route, and too long route steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]

[0080] Add compound 1 (22.22g, 100mmol) and ethyl 2-cyanoacetoacetate 2a (11.88g, 105mmol) and ethanol (111mL) into the three-necked flask, stir and dissolve and drop diisopropylethylamine (25.85g, 200mmol ), adding sulfur powder (3.37g, 105mmol), stirring evenly and then heating to 75-80°C to react overnight. Add dilute hydrochloric acid (3%, 222mL) to quench the reaction at the end of the reaction, spin off part of the ethanol, add ethyl acetate for extraction and discard the organic phase, collect the water phase, add sodium bicarbonate solution to adjust the pH to 8-9, and precipitate a large amount of solid , and slowly cooled to crystallize, filtered and dried to obtain compound 3a (29.18g, 83.5%).

[0081] MS(ESI)m / z=350.1[M+H] +

[0082] 1 H NMR (500MHz, DMSO) δ8.23(d, J=8.8Hz, 2H), 7.79(d, J=8.8Hz, 2H), 7.60(s, 2H), 4.24(q, J=7.2Hz, 2H ),3.55(s,2H),2.07(s,6H),1.32(t,J=7.2Hz,3H).

[0083] In embodiment 1, 2-cyanoacetoacetate ethyl ester can be used 2-c...

Embodiment 2

[0085]

[0086]Add compound 1 (22.22g, 100mmol) and isopropyl 2-cyanoacetoacetate 2b (13.35g, 105mmol) and isopropanol (111mL) into the three-necked flask, stir and dissolve and drop diisopropylethylamine (25.85 g, 200mmol), add sulfur powder (3.37g, 105mmol), stir evenly and heat to 80-85°C to react overnight. Add dilute hydrochloric acid (3%, 222mL) to quench the reaction at the end of the reaction, spin off part of the isopropanol, add ethyl acetate to extract and discard the organic phase, collect the aqueous phase, add sodium bicarbonate solution to adjust the pH to 8-9, and precipitate A large amount of solid was crystallized by slow cooling, and filtered and dried to obtain compound 3b (30.71g, 84.5%).

[0087] MS(ESI)m / z=364.2[M+H] +

[0088] 1 H NMR (500MHz, DMSO) δ8.24 (d, J = 8.8Hz, 2H), 7.80 (d, J = 8.8Hz, 2H), 7.58 (s, 2H), 4.74-5.08 (m, 1H), 3.53 (s,2H),2.08(s,6H),1.18(d,J=6.4Hz,3H).

[0089] In embodiment 2, 2-cyanoacetoacetate isopropyl ester can use 2-...

Embodiment 3

[0091]

[0092] Compound 3a (34.94 g, 100 mmol) was added into a three-necked flask, and 175 mL of dichloromethane was added and stirred to dissolve. The reaction flask was cooled to 0-5°C in an ice bath, triethylamine (20.24g, 200mmol) was added, methyl chloroformate (10.39g, 110mmol) was slowly added dropwise, and after the addition was completed, the temperature was raised to room temperature for overnight reaction. Add water (349mL) at the end of the reaction, add 175mL dichloromethane to extract and discard the aqueous phase, collect the organic phase, wash with water, concentrate to a small volume, add n-heptane, slowly cool and crystallize, filter and dry to obtain compound 4a (35.90g, 88.1%). MS(ESI)m / z=408.1[M+H] + , 1 H NMR (400MHz, CDCl 3 )δ10.55(s,1H),8.26(d,J=8.8Hz,2H),7.72(d,J=8.8Hz,2H),4.30-4.56(m,2H),3.79(s,3H), 3.66(s,2H),2.12(s,6H),1.33(t,J=7.2Hz,3H).

[0093] In Example 3, methyl chloroformate can be replaced by ethyl chloroformate, isopropyl chlorof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com