Photocatalytic cement mortar containing boron, carbon and nitrogen and preparation method thereof

A technology of cement mortar and boron carbon nitrogen, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Problems such as the contact area of the light source and the production method of photocatalytic cement mortar have not been seen, so as to achieve the effect of promoting large-scale application, improving lubricity, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

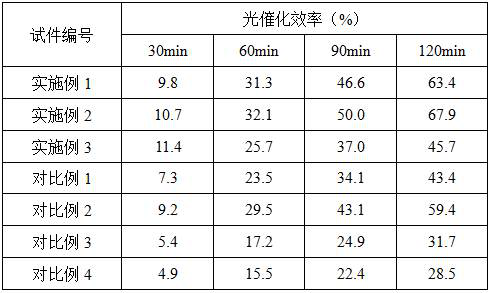

Embodiment 1

[0044]In this embodiment, the raw material ratio of the cement mortar by weight is: 4 parts of cement, 10 parts of machine-made sand, 0.004 part of boron carbon nitrogen, 0.005 part of nano-montmorillonite, and 2 parts of deionized water.

[0045] In the present embodiment, the preparation method of photocatalytic cement mortar is carried out as follows:

[0046] Step 1: adding nano-montmorillonite to tap water, using a disperser to stir at a speed of 6000r / min for 30 minutes to obtain a film-attached liquid; the volume of the tap water is 0.5 times the volume of the machine-made sand;

[0047] Step 2: Stir the machine-made sand with a washing bucket for 5 minutes, put it on the mesh screen to dry for 25 minutes, and then place it in an oven to heat and dry; add the dried machine-made sand to the film-attached liquid and stir for 5 minutes, then Pour it into a tray and place it in an oven to heat and dry it, so that the nano-montmorillonite adheres to the surface of the machin...

Embodiment 2

[0052] In this embodiment, the raw material ratio of the cement mortar by weight is: 5 parts of cement, 15 parts of machine-made sand, 0.005 part of boron carbon nitrogen, 0.006 part of nano-montmorillonite, and 2.5 parts of deionized water.

[0053] In the present embodiment, the preparation method of photocatalytic cement mortar is carried out as follows:

[0054] Step 1: adding nano-montmorillonite to tap water, using a disperser to stir at a speed of 5500r / min for 40 minutes to obtain a film-attached liquid; the volume of the tap water is 0.52 times the volume of the machine-made sand;

[0055] Step 2: Stir the machine-made sand with a washing bucket for 5.5 minutes, put it on a mesh screen to dry for 30 minutes, and then place it in an oven to heat and dry; add the dried machine-made sand to the film-attached liquid and stir for 6 minutes, then Pour it into a tray and place it in an oven to heat and dry it, so that the nano-montmorillonite adheres to the surface of the ma...

Embodiment 3

[0060] In this embodiment, the raw material ratio of the cement mortar by weight is: 8 parts of cement, 25 parts of machine-made sand, 0.015 parts of boron carbon nitrogen, 0.011 parts of nano-montmorillonite, and 4.5 parts of deionized water.

[0061] In the present embodiment, the preparation method of photocatalytic cement mortar is carried out as follows:

[0062] Step 1: adding nano-montmorillonite to tap water, using a disperser to stir at a speed of 7000r / min for 30 minutes to obtain a film-attached liquid; the volume of the tap water is 0.6 times the volume of the machine-made sand;

[0063] Step 2: Stir the machine-made sand with a washing bucket for 6 minutes, put it on a mesh screen to dry for 35 minutes, and then place it in an oven to heat and dry; add the dried machine-made sand to the film-attached liquid and stir for 6.5 minutes, then Pour it into a tray and place it in an oven to heat and dry it, so that the nano-montmorillonite adheres to the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com