Method for recovering cefuroxime acid from cefuroxime acid waste residue liquid

A technology of cefuroxime acid and waste residue liquid, which is applied in the direction of organic chemistry, can solve the problems of low production cost, and achieve the effects of low production cost, simple reaction process and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of polymer supported catalyst in the embodiment is as follows:

[0030] Immerse 5-6g of polymer material in 50ml of absolute ethanol for 2-3 hours, under the protection of nitrogen, add 2-3g of Lewis acid to reflux for 2-2.5 hours, cool to room temperature, filter with suction to remove the solvent, and wash the filter cake with acetone , drying at room temperature, prepared. Where the Lewis acid is TiCl 4 , AlCl 3 or BBr 3 ; The polymer material is one or both of polyvinyl chloride or polystyrene.

Embodiment 1

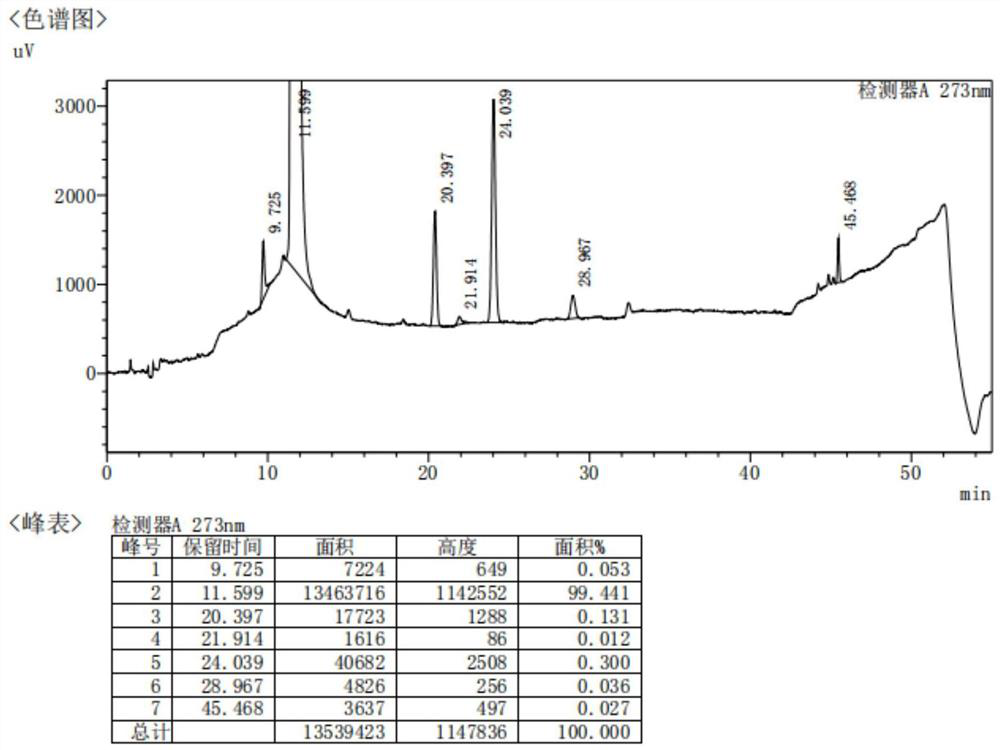

[0032] 40g cefuroxime acid waste residue liquid (HPLC detection trans isomer peak area ratio is 6%) was dissolved in 200ml water, filtered to obtain a clear solution, adding polymer-loaded catalyst PVC-AlCl in the clear solution 3 , PVC-AlCl 3 % of the total mass of the clarified solution, stirred and reacted at 20° C. for 5 h, and distilled under reduced pressure to obtain 15 g of cefuroxime acid product. The cefuroxime acid product is detected by HPLC, and its chromatogram is as follows: figure 1 Shown: the peak area ratio of the trans isomer is 0.131%. Based on the total mass of cefuroxime acid waste residue liquid, the yield of cefuroxime acid product was 37.5%, and the purity was 99.441%.

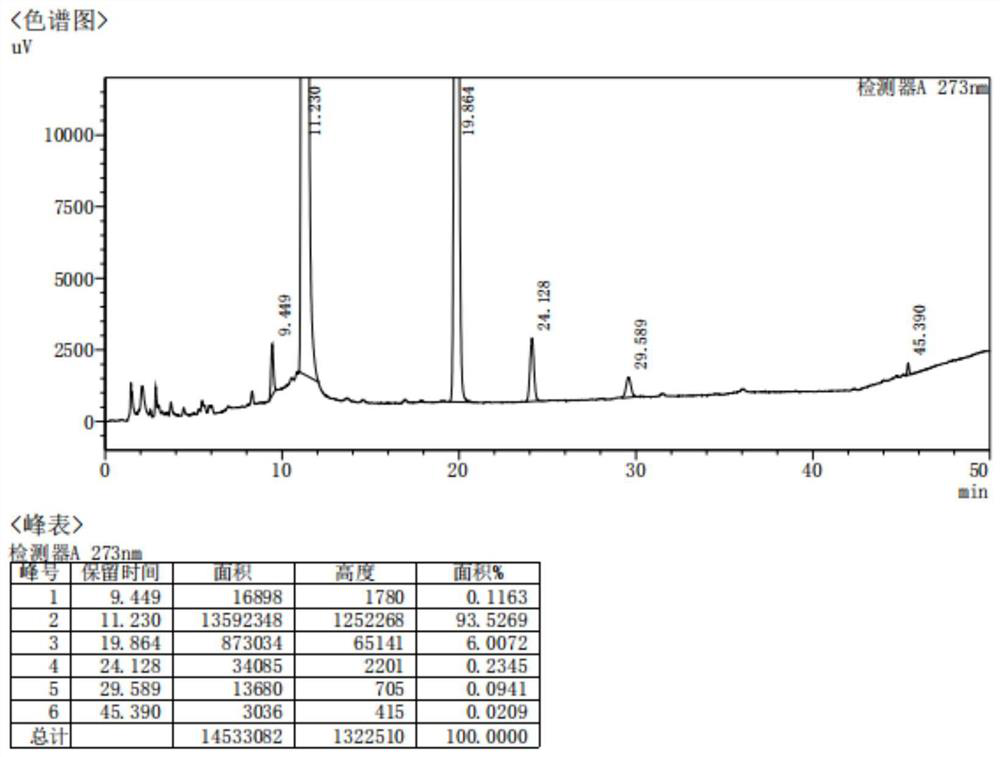

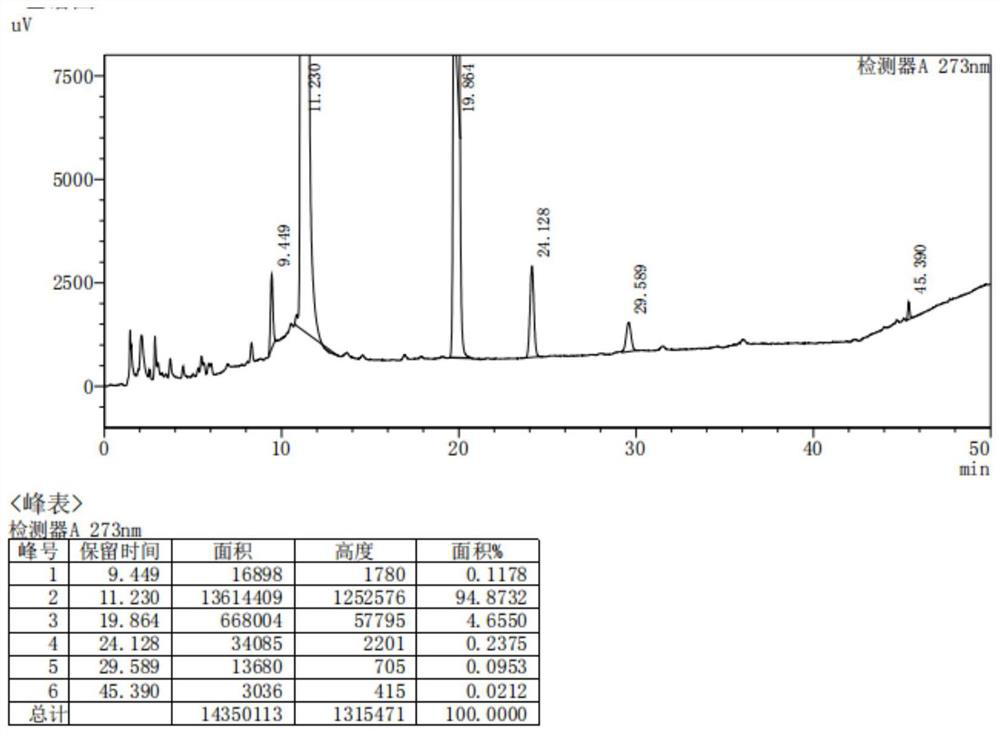

Embodiment 2~7

[0034] The process of reclaiming cefuroxime acid from the cefuroxime acid waste residue liquid is the same as in Example 1, adjusting the reaction temperature, the reaction time, the consumption of the cefuroxime acid waste residue liquid, the type and amount of the solvent, the type and the amount of the polymer-loaded catalyst, specifically The data are shown in Table 1.

[0035] The data sheet in the embodiment 2~7 of table 1

[0036]

[0037]

[0038] The cefuroxime acid products in Examples 1-7 were tested for quality. The products obtained in Examples 1-7 were all white crystalline powders, all of which met the product requirements, and the content of trans isomers was all less than 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com