High-activity mercury removal adsorbent and preparation method thereof

An adsorbent and high-activity technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high energy consumption and waste gas treatment, and achieve the goal of increasing reaction rate, reducing preparation cost, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

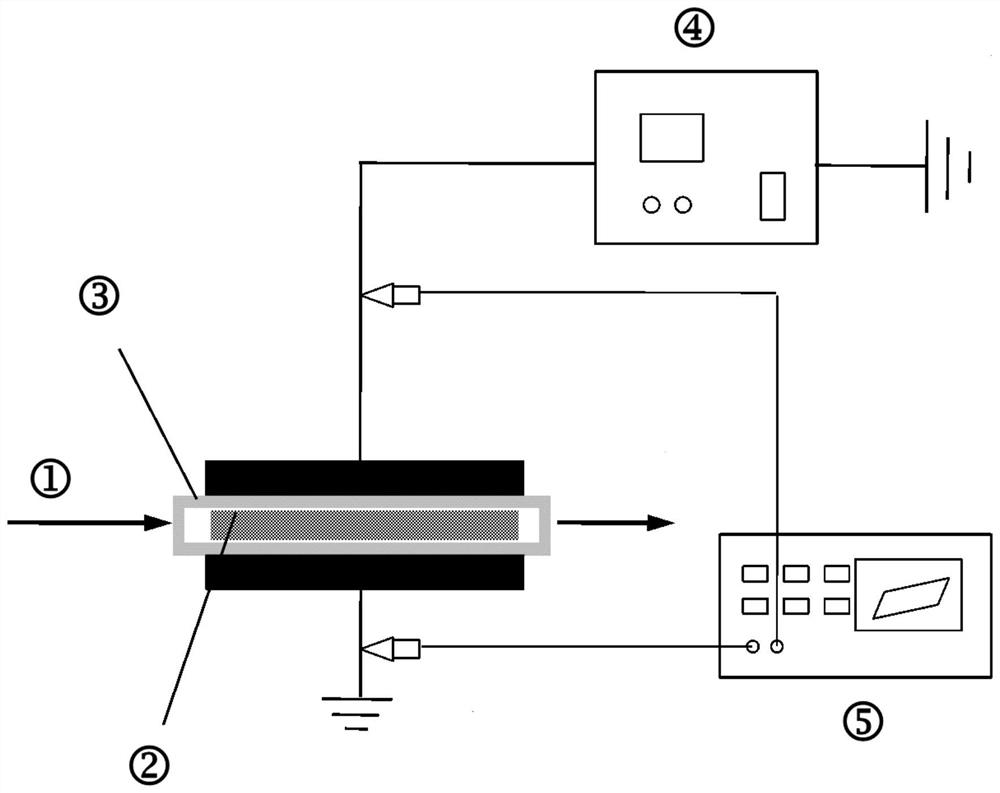

[0034] figure 1 It is a diagram of the preparation device of the highly active mercury-removing adsorbent used in the preferred embodiment of the present invention. The elemental sulfur is heated at 500°C to generate sulfur-containing vapor. The volume concentration of elemental sulfur in the sulfur-containing vapor is 10%, and the balance gas is nitrogen . The sulfur-containing steam is passed into the quartz reactor 3 through the sulfur-containing steam inlet 1 at a flow rate of 100 ml / min, and the adsorbent carrier 2 is placed in the quartz reactor 3 . When the sulfur-containing vapor fills the quartz reactor 3, turn on the plasma power supply 4, adjust the output voltage of the plasma generator to 30kV, and the frequency to 15kHz (read by the oscilloscope 5). After reacting at 26° C. for 2 minutes, a highly active mercury-removing adsorbent can be obtained in the quartz reactor 3 .

[0035] The obtained highly active mercury-removing adsorbent was placed on a fixed-bed b...

Embodiment 2

[0037] Heating elemental sulfur at 600°C generates sulfur-containing vapor, and the volume concentration of elemental sulfur in the sulfur-containing vapor is 100%. The sulfur-containing vapor is passed into the quartz reactor 3 through the sulfur-containing vapor inlet 1 at a flow rate of 1 ml / min, and the adsorbent carrier 2 is placed in the quartz reactor 3 . When the sulfur-containing vapor fills the quartz reactor 3, turn on the plasma power supply 4, adjust the output voltage of the plasma generator to 40kV, and the frequency to 20kHz (read by the oscilloscope 5). After reacting at 23° C. for 3 minutes, a highly active mercury-removing adsorbent can be obtained in the quartz reactor 3 .

[0038] Take 10 mg of highly active mercury removal adsorbent and place it on a fixed bed bench for mercury adsorption test. The initial mercury concentration in the adsorption test was 90 μg / m 3 , the adsorption temperature is 110℃, the carrier gas (N 2 ) The flow rate is 1L / min. Th...

Embodiment 3

[0040] Heating elemental sulfur at 550°C generates sulfur-containing vapor, and the volume concentration of elemental sulfur in the sulfur-containing vapor is 20%. The sulfur-containing steam is passed into the quartz reactor 3 through the sulfur-containing steam inlet 1 at a flow rate of 200ml / min, and the adsorbent carrier 2 is placed in the quartz reactor 3 . When the sulfur-containing vapor fills the quartz reactor 3, turn on the plasma power supply 4, adjust the output voltage of the plasma generator to 35kV, and the frequency to 10kHz (read by the oscilloscope 5). After reacting at 27° C. for 5 minutes, a highly active mercury-removing adsorbent can be obtained in the quartz reactor 3 .

[0041] Take 10 mg of highly active mercury removal adsorbent and place it on a fixed bed bench for mercury adsorption test. The initial mercury concentration in the adsorption test was 90 μg / m 3 , the adsorption temperature is 110℃, the carrier gas (N 2 ) The flow rate is 1L / min. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com