Vegetable organic fertilizer and preparation method thereof

A technology for organic fertilizers and vegetables, applied in the field of vegetable organic fertilizers and its preparation, can solve problems such as lack of fertility, achieve lasting fertility, increase specific surface area and reaction performance, and improve surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

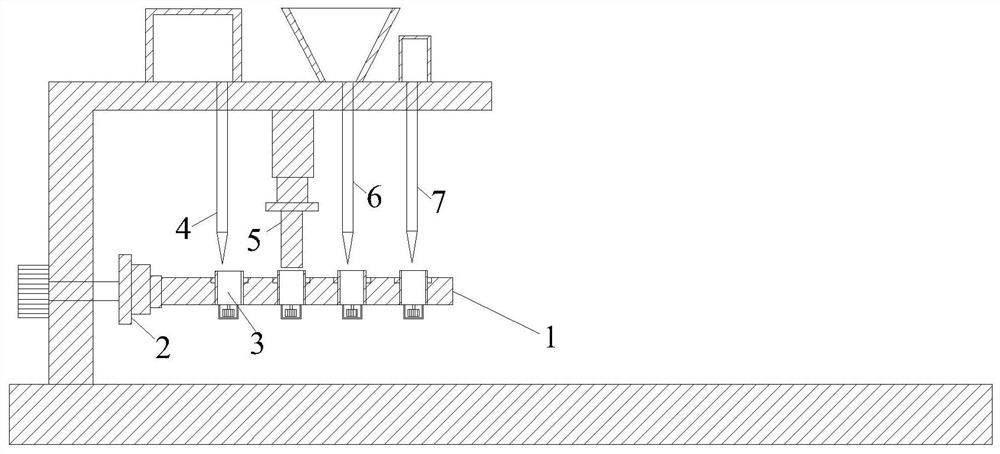

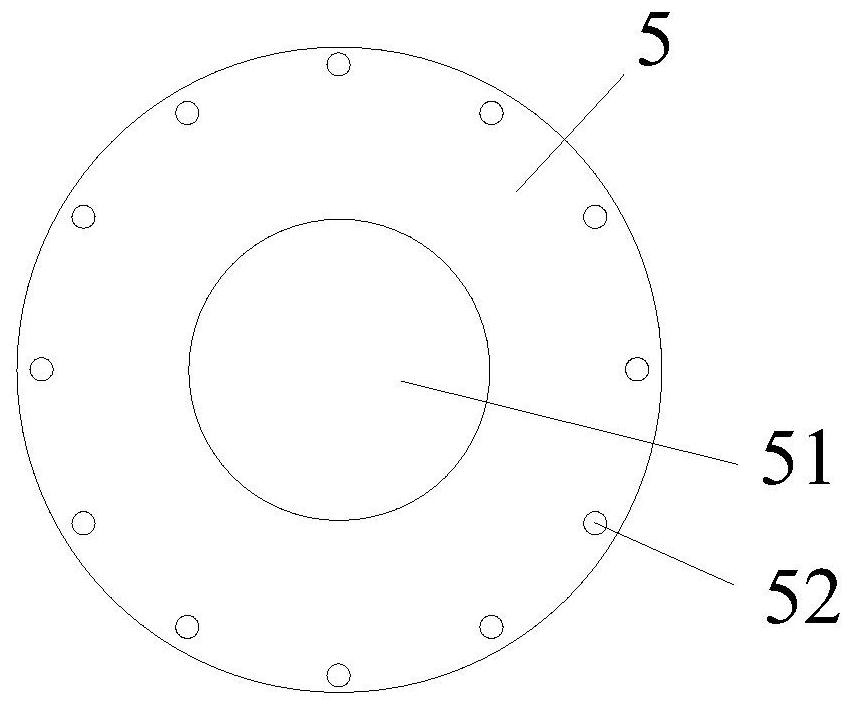

Image

Examples

Embodiment 1

[0039] A kind of preparation method of vegetable organic fertilizer provided by the present embodiment comprises the following steps:

[0040] S101. Pretreatment of crop stalks, using corn stalks as crop stalks;

[0041] Air-dry the corn stalks first and crush them into powder, then place the corn stalk powder in a steam environment at 85°C for 15 minutes of moist heat treatment, then ultrasonically pretreat the corn stalk powder for 10 minutes before adding liquid organic fertilizer, ultrasonic The frequency is 40kHz, the power is 300W, and the temperature is raised to 80°C, reacted for 30 minutes, cooled to room temperature, and dried to obtain pretreated cornstalk powder;

[0042] S102, composting and fermenting the animal manure to obtain an organic fertilizer base fertilizer, which is dried and pulverized, and mixed with the pretreated crop straw powder to obtain a mixed fertilizer, which is set aside;

[0043] S103. Coating the mixture of the organic fertilizer base fer...

Embodiment 2

[0046] S101. Pretreatment of crop stalks, the crop stalks are selected from wheat stalks;

[0047] Air-dry the wheat stalks first and crush them into powder, then place the wheat stalk powder in a steam environment at 100°C for 15 minutes of moist heat treatment, then ultrasonically pretreat the wheat stalk powder after the heat treatment for 15 minutes, then add liquid organic fertilizer, ultrasonic The frequency is 40kHz, the power is 300W, the temperature is raised to 70°C, after 50 minutes of reaction, it is cooled to room temperature, and dried to obtain the pretreated wheat straw powder;

[0048] S102, composting and fermenting the animal manure to obtain an organic fertilizer base fertilizer, which is dried and pulverized, and mixed with the pretreated crop straw powder to obtain a mixed fertilizer, which is set aside;

[0049]S103. Coating the mixture of the organic fertilizer base fertilizer and the pretreated crop straw powder as a core material inside the capsule wa...

Embodiment 3

[0051] A kind of preparation method of vegetable organic fertilizer provided by the present embodiment comprises the following steps:

[0052] S101. Pretreatment of crop stalks, the crop stalks are selected from wheat stalks;

[0053] Air-dry the crop straws first and crush them into powder, then place the crushed crop straws in a steam environment at 80°C for 10 minutes of moist heat treatment, and then ultrasonically pretreat the moist heat treated crop straws for 20 minutes before adding liquid organic fertilizer. The liquid organic fertilizer is liquid organic fertilizer rich in trace elements; ultrasonic pretreatment with ultrasonic frequency 40kHz, power 300W, heating up to 75°C, reacting for 40min, cooling to room temperature, drying, and obtaining pretreated crop straw powder;

[0054] S102. According to the different nutrient requirements of vegetables in different growth periods, adjust the mixing ratio of organic fertilizer base fertilizer and trace elements in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com