Composite adsorbent with 3DOM structure as well as preparation method and application thereof

A composite adsorption and 3DOM technology, applied in the direction of separation methods, chemical instruments and methods, silicon compounds, etc., can solve the problem of limited adsorption capacity of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

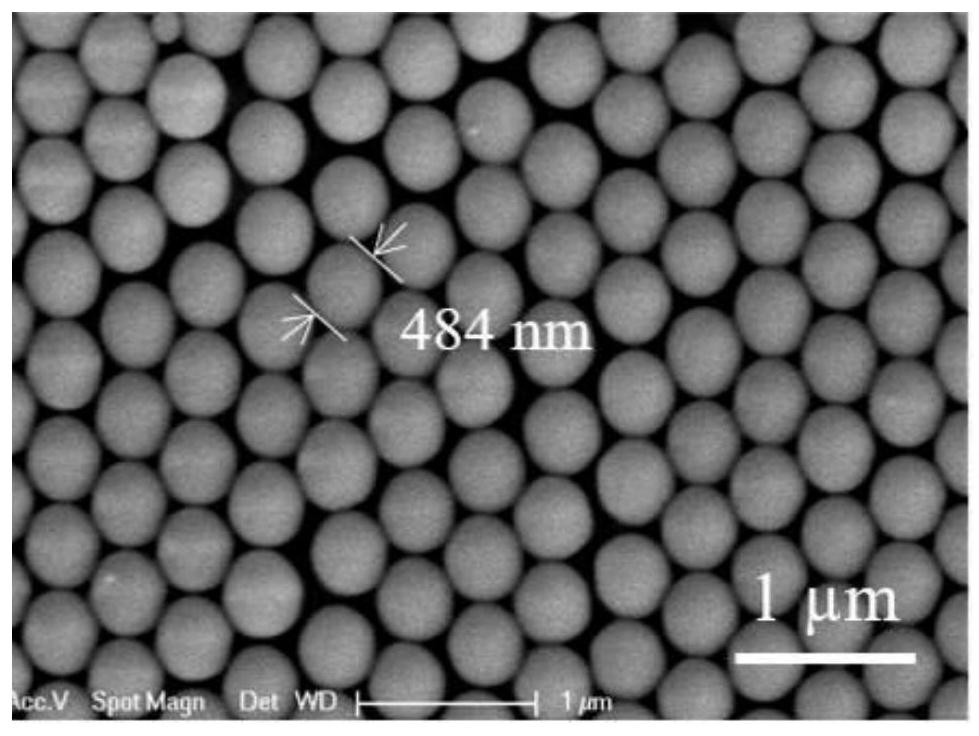

[0046] The preparation method of the 3DOM structure composite adsorbent of the present invention comprises the following steps:

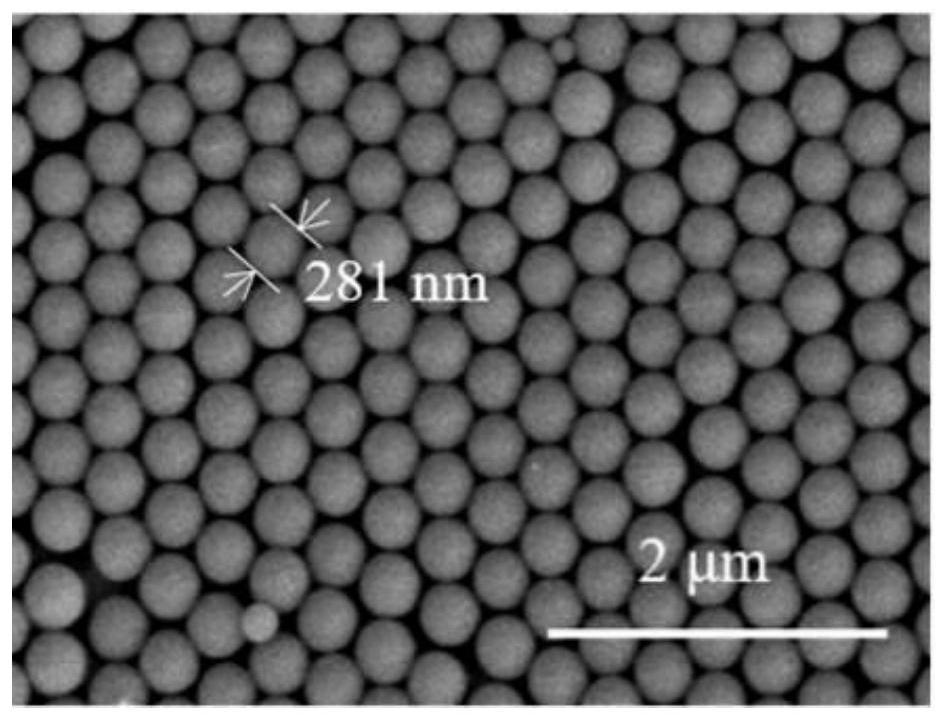

[0047] (1) Preparation of colloidal crystal template

[0048] Use neutral / basic alumina chromatography column to treat styrene / methyl methacrylate for 1-5 times to de-inhibitor. After treatment, use soap-free emulsion polymerization to prepare submicron with different diameters (100-300nm) grade colloidal crystal microspheres.

[0049] (2) Preparation of precursor solution

[0050] The mass ratio of the metal oxide in the composite adsorbent to the total adsorbent is calculated as 30%-100%, and a certain amount of Fe source and Zn source are weighed and dissolved in a mixed solution of alcohol to prepare a metal salt of 0.5-2mol / L solution. Add citric acid to the above solution according to the ratio of 1-2 times the amount of metal salt substance, heat, mix and stir to obtain a metal solution chelated by citric acid. Weigh a certain amount of s...

Embodiment 1

[0058] The preparation process of the present embodiment 3DOM structure composite adsorbent comprises the following processes:

[0059] Preparation of PS colloidal crystal template microspheres:

[0060] The styrene solution was treated with a polymerization inhibitor, and the neutral alumina (specially used for chromatography) dried at 105°C for 12 hours was used as a packed column, and the styrene solution was dropped into the neutral alumina chromatography column drop by drop, and passed through the The styrene monomer that has been removed from the polymerization inhibitor is processed by the column analysis. Add 300ml of deionized water into a 500ml three-necked flask, connect the mechanical stirring device, gas communication device and condenser tube, and feed 50ml / minN 2 , while raising the temperature to 70°C and stirring continuously for 1h. Pour 6ml of styrene monomer into a three-necked flask. After 20min, add the corresponding amount of initiator dropwise (K 2 ...

Embodiment 2

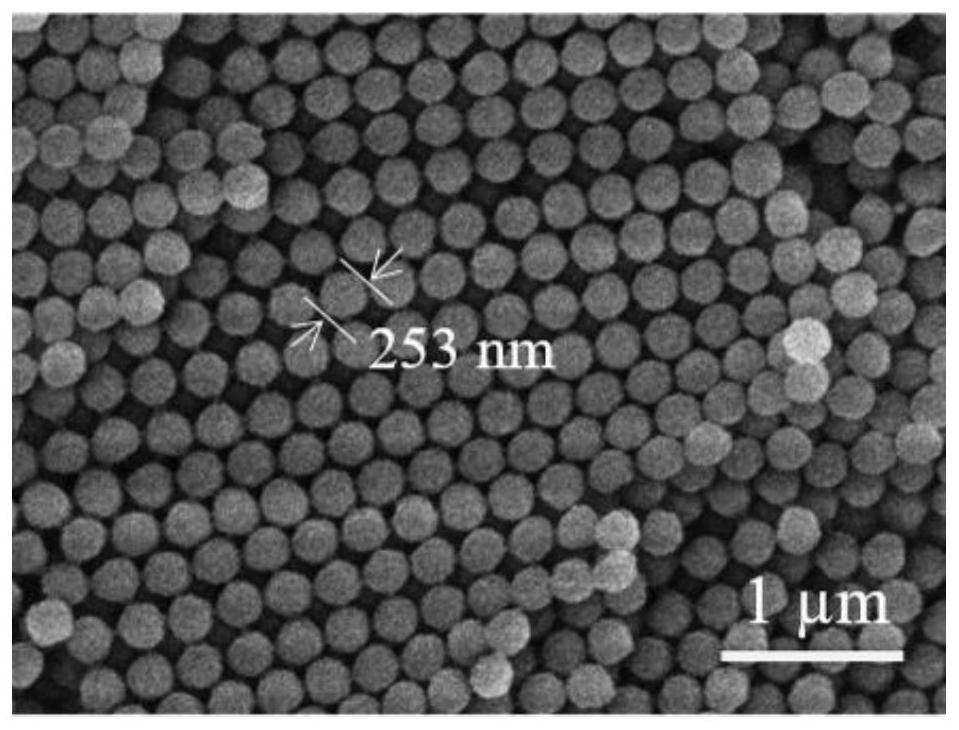

[0067] Preparation of PMMA colloidal crystal template microspheres:

[0068] The methyl methacrylate solution is treated with a polymerization inhibitor, and the basic alumina (special for chromatography) that has been dried at 105°C for 12 hours is loaded into the packed column, and the methyl methacrylate solution is dropped into the chromatography column drop by drop. , to obtain the methyl methacrylate monomer having removed the polymerization inhibitor. Add 300ml of deionized water into a 500ml three-necked flask, connect the mechanical stirring device, gas communication device and condenser tube, and feed 50ml / minN 2 , while raising the temperature to 70°C and stirring continuously for 1h. Pour 22.5 mL of MMA monomer containing 0.03 wt % p-hydroxybenzoic acid into a three-necked flask. After continuous stirring for 20 min, 10 mL of 100 g / mL KPS aqueous solution was added dropwise to initiate the polymerization reaction. After 1 h, the polymerization reaction was compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com